Open caisson type tower crane foundation capable of being quickly assembled

A caisson type and tower crane technology, which is applied in infrastructure engineering, caisson, construction, etc., can solve the problems of long waiting period for concrete curing, inability to achieve timely construction, and long construction period, and achieve easy hoisting and assembly, saving construction. Time, the effect of simplifying the steps of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

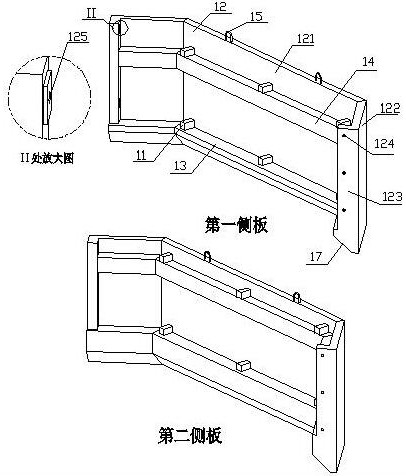

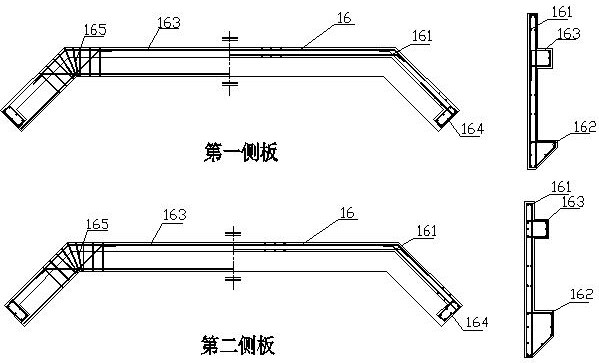

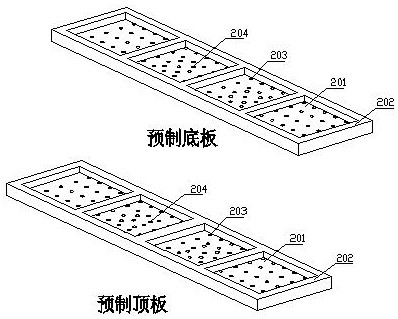

[0026] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0027] In the description of the present invention, it is to be noted that the terms "within", "outside", "horizontal", "longitudinal", "height", "width", "bottom surface", "horizontal plane", "cross section", The orientation or positional relationship of "longitudinal section", "upper surface", "lower surface", "corner" indication is based on the orientation or positional relationship shown in the drawings, is only for ease of describing the invention and simplified description...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com