Pipe piece hoisting system and hoisting method

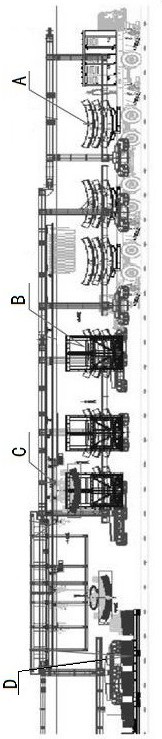

A segment and segment crane technology, which is applied to earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problem of not being suitable for large-slope segment hoisting and transportation, so as to improve segment hoisting efficiency and construction safety factor, The effect of reducing risk and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

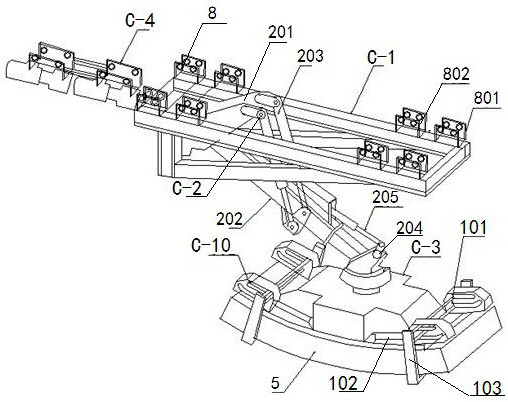

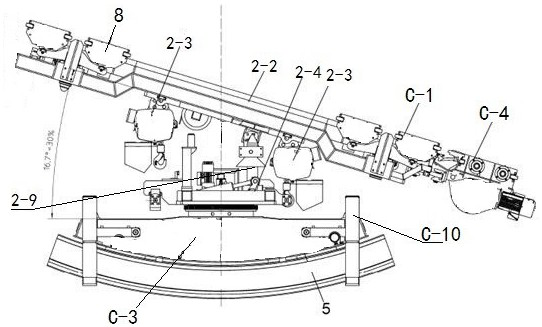

Examples

Embodiment 6

[0077] Embodiment 6: A lifting method of the large-slope segment lifting system as described in Embodiment 5, the steps are as follows:

[0078] S1: The rubber wheel transportation device A adjusts the transported segment by rotating the leveling mechanism, so that the transported segment is always in a horizontal state during the transportation process; to complete the efficient transportation of the segment in the construction of a large slope tunnel.

[0079] S2: The rubber tire transport device A transports the segment to the working position of the segment quick unloading device B, and the segment quick unloading device B prepares for unloading the segment on the rubber tire transport device A; adjusts the automatic adjustment according to the slope of the tunnel leveling mechanism, so that the chassis assembly is always in a vertical state; specifically, one end of the leveling cylinder is connected to the trailer, and the other end is connected to the chassis assembly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com