Circulating type bidirectional power generation system and use method thereof

A power generation system, circulation technology, applied in hydropower, engine components, machines/engines, etc., can solve problems such as insufficient power generation and small water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

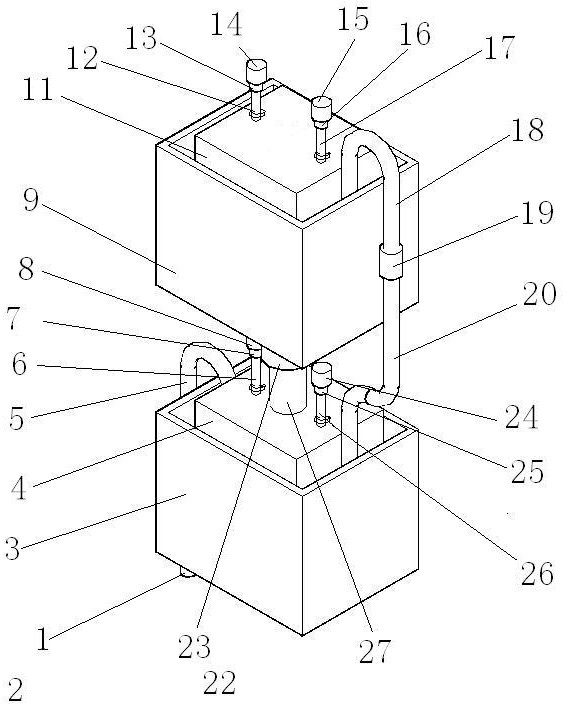

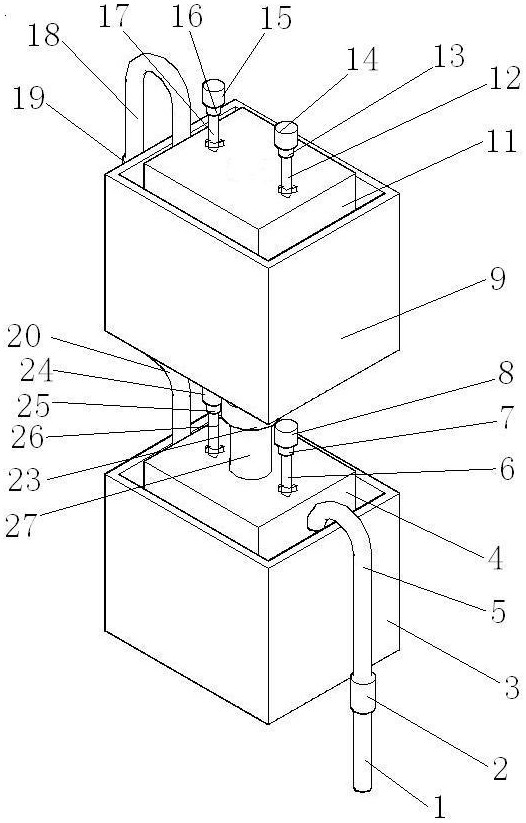

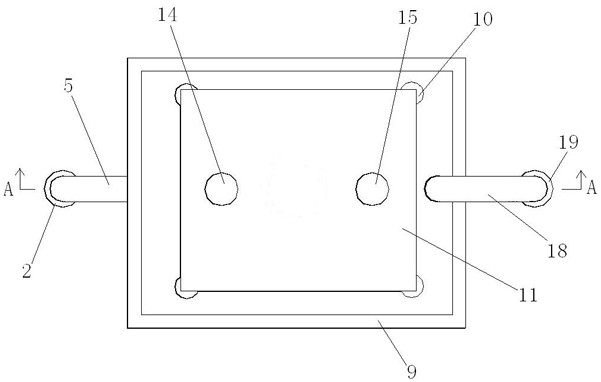

[0023] A circulating bidirectional power generation system of the present invention is characterized in that the water outlet pipe 5 and the water inlet pipe B20 are respectively inserted into the left and right sides of the reservoir A3, the water outlet pipe 5 is connected to the water pump A2, the water pump A2 is connected to the water inlet pipe A1, and the water inlet pipe B20 is connected to Water pump B19, water pump B19 is connected to outlet pipe B18, air storage chamber A4 is installed in the middle of reservoir A3 through support column B28, air inlet pipe A6 and suction pipe B26 are respectively installed at both ends of air storage chamber A4, and air inlet pipe A6 is connected to the air motor A7, the air motor A7 is connected to the generator A8, the suction pipe B26 is connected to the air motor D25, the air motor D25 is connected to the generator E24, and the middle part of the gas storage chamber A4 is installed with a downpipe B27, and the downpipe B27 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com