High-efficiency air-cooling forced heat dissipation brake pad and manufacturing method thereof

A brake pad and high-efficiency technology, which is applied in the field of automobile brake pads, can solve the problems of poor braking ability of brake pads, complex ternary structure technology, and brittle edges and corners, etc., and achieve smooth braking, low noise, and forced The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the invention.

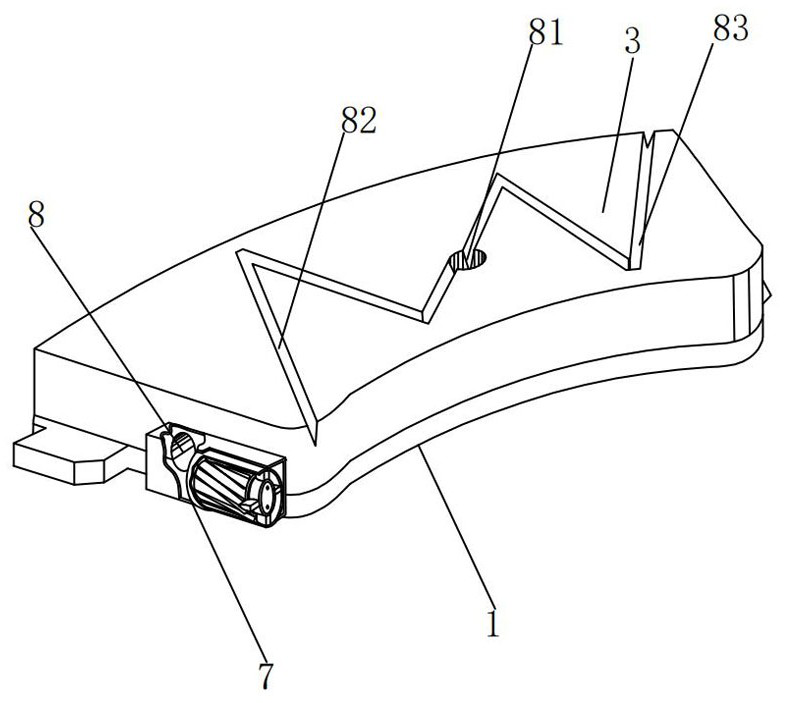

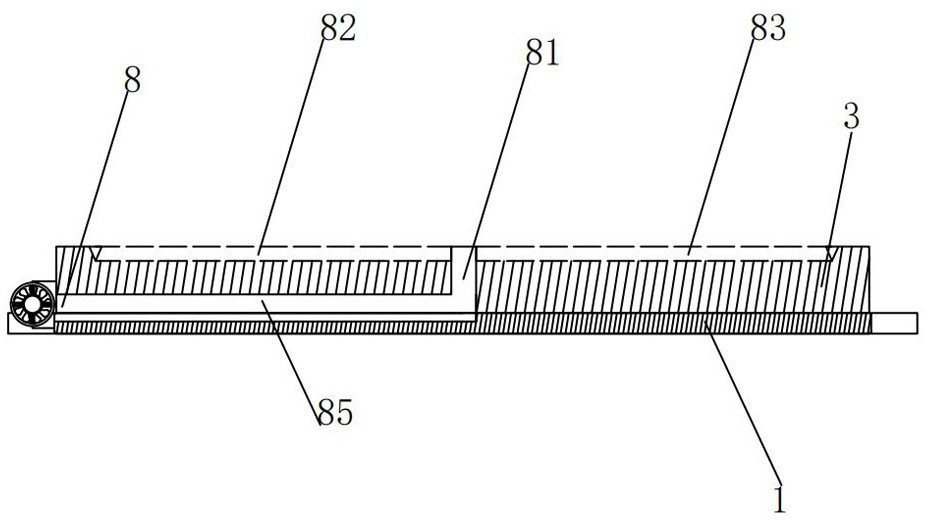

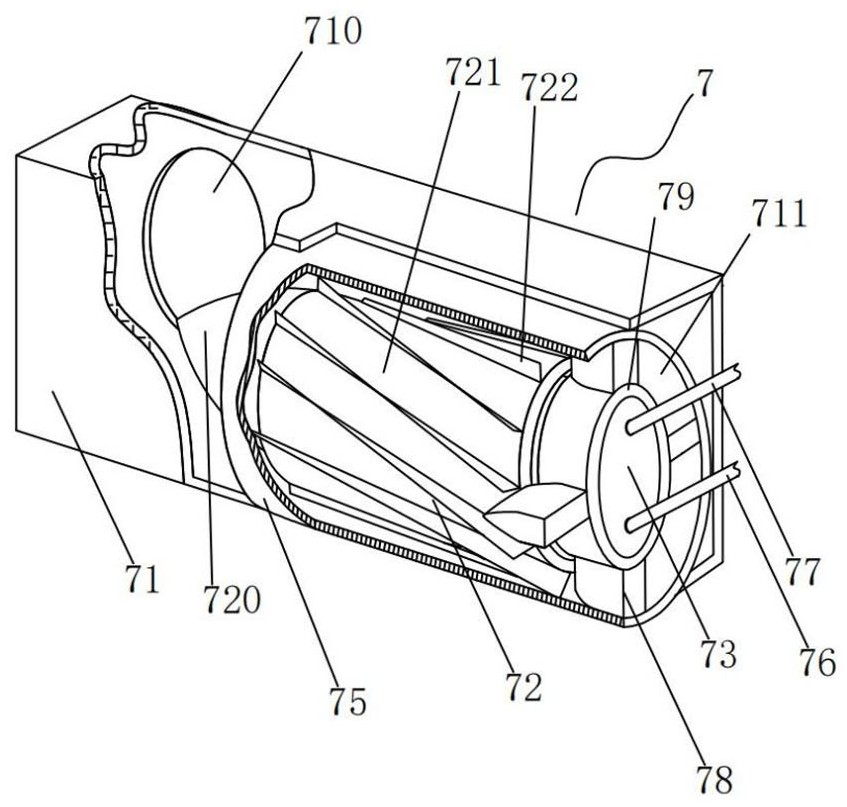

[0027] Such as figure 1 , 2 , 3, 4, a high-efficiency air-cooled forced heat dissipation brake pad and its manufacturing method, the brake pad includes a back plate 1, and the back plate 1 is provided with a friction material 3, characterized in that: the friction material 3 There is a vertical heat dissipation well 81 in the middle, and a heat dissipation channel 85 is arranged horizontally inside the friction material 3. The vertical heat dissipation well 81 communicates with one end of the heat dissipation channel 85. The outer part of the friction material is provided with a heat dissipation outlet 3, and the heat dissipation outlet 3 communicates with the other end of the heat dissipation channel 85, the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com