Shield underground bedrock boulder blasting method

An underground foundation and boulder technology, applied in blasting and other directions, can solve the problems of ground deformation and poor blasting effect, and achieve good blasting effect, increase safety and blasting uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0045] The invention provides a method for blasting underground bedrock and boulders with shield tunneling, which includes the following steps:

[0046] S1: Through on-the-spot survey of the blasting area at the construction site, comprehensively consider the terrain, lithology and surrounding environmental conditions of the blasting area;

[0047] S2: According to the relevant technical requirements of the engineering department for blasting operations, it is advisable to adopt the differential control blasting method during blasting to reasonably disperse the explosive energy;

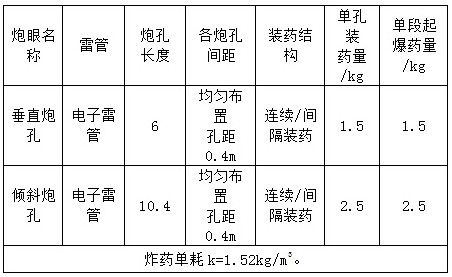

[0048] S3: drilling arrangement;

[0049] Step 1: Due to the impact of the transformer on the drilling work, in order to ensure the bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com