Self-cleaning fine spectrum water body parameter measuring device and method based on turbidity correction

A parameter measurement and self-cleaning technology, which is applied in measurement devices, scattering characteristic measurement, material analysis by optical means, etc., can solve the problems of low accuracy of multi-parameter synchronous monitoring of water bodies, and difficulty in cleaning and suppressing sediments in optical windows. Achieve the effect of avoiding the decline in detection accuracy, reducing after-sales costs, and having strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

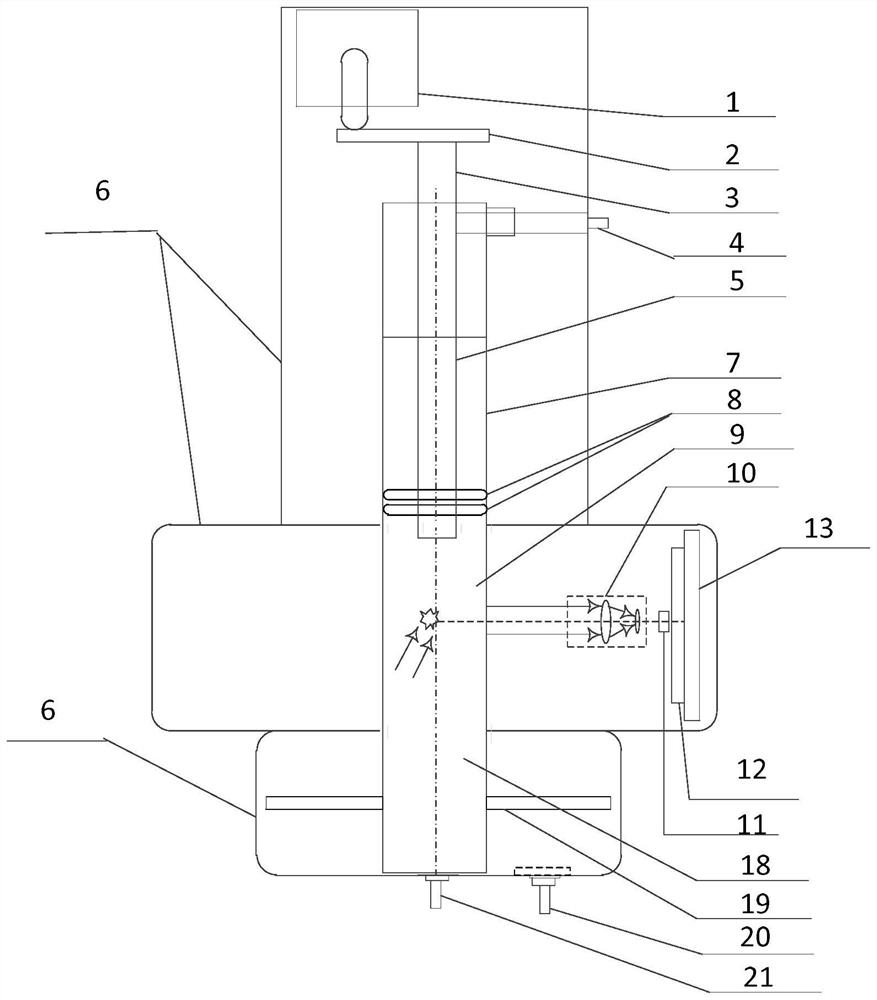

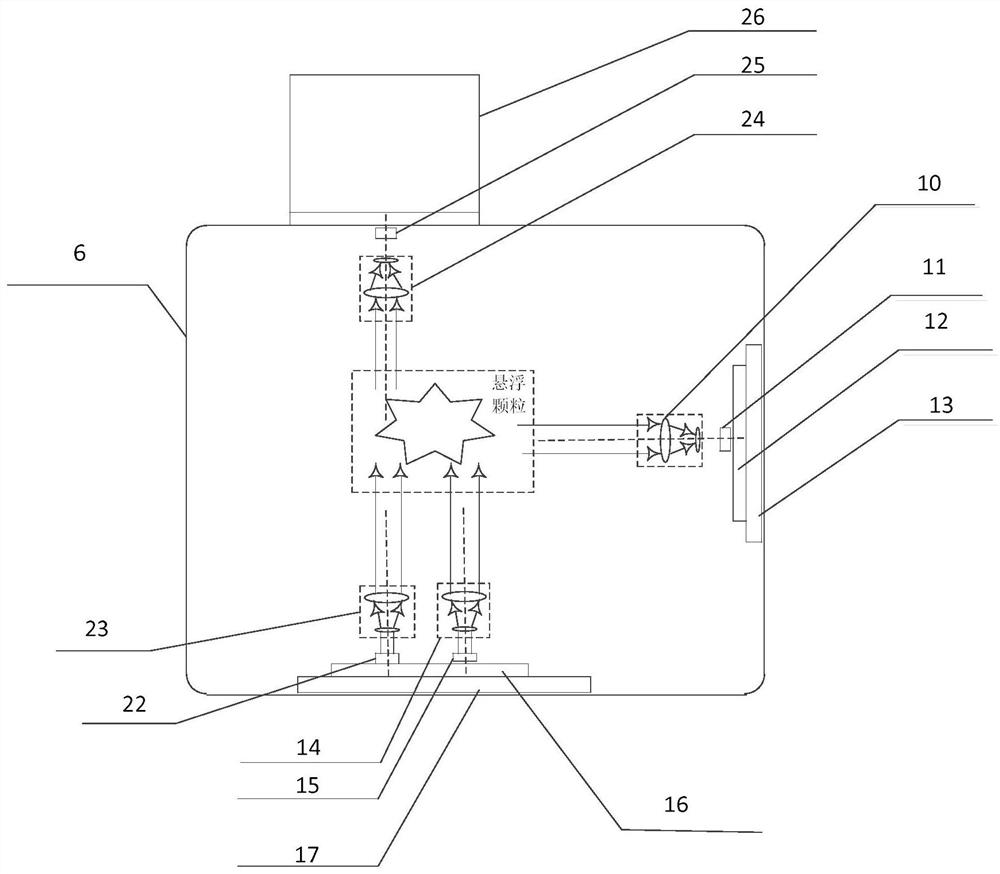

[0055] see figure 1 and figure 2 , the present embodiment provides a self-cleaning fine-spectrum water body parameter measurement device based on turbidity correction, the device includes a housing 6, a water holding tube arranged in the housing 6, a driving module, a drainage module, and a detection module And signal processing output module.

[0056] The lower end of the casing 6 is provided with a water inlet 21, and the casing 6 has a water body containing pipe surrounded by metal plates. The inside of the water body containing pipe is hollow and has a transition chamber 7, a scattering chamber 9 and The buffer chamber 18, the transition chamber 7, the scattering chamber 9 and the buffer chamber 18 have the same cross-sectional size perpendicular to the extension direction of the water body holding pipe and are rectangular in shape; the upper end of the transition chamber 7 is connected to the drainage module, and the lower end of the buffer chamber 18 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com