Remote centralized system of aircraft engine hydraulic product test equipment and control method

A product test and test equipment technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of difficulty in editing automatic control programs and high technical level requirements for test operators, and achieve simple design, The effect of avoiding security risks and simplifying the editing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

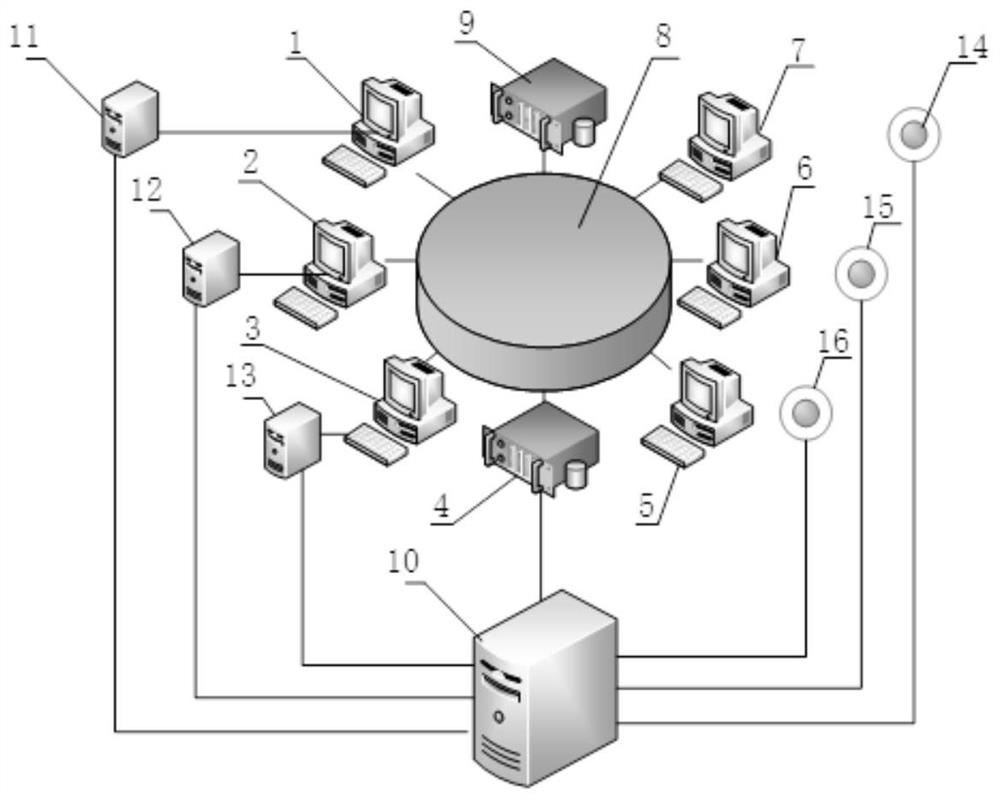

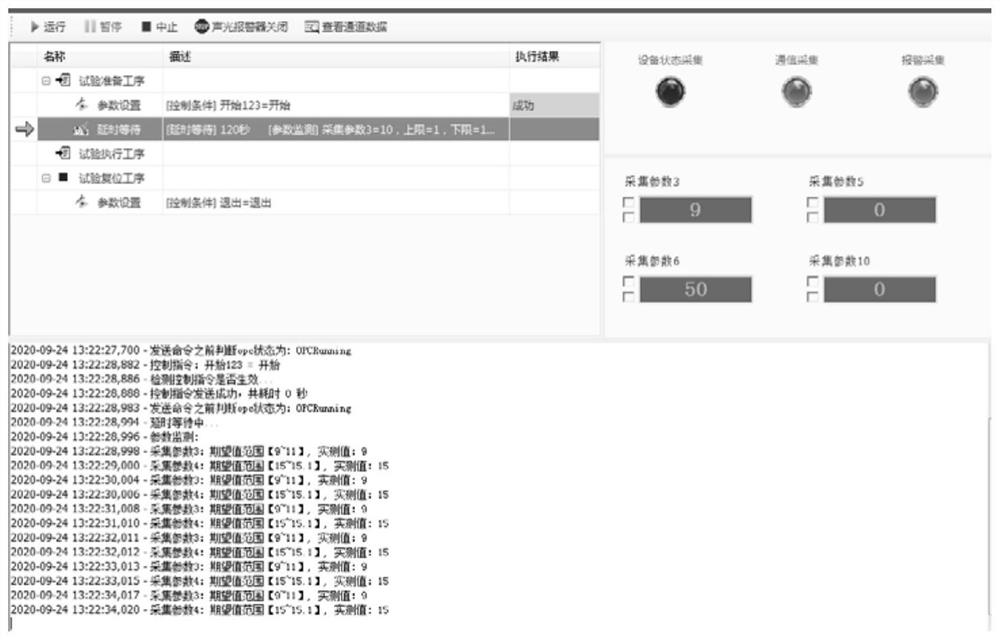

[0035] Example 1. A remote centralized system for Hangfa hydraulic product test equipment, which is composed of Figure 1-3 As shown, it consists of test equipment industrial computer Ⅰ1, test equipment industrial computer Ⅱ2, test equipment industrial computer Ⅲ3, centralized control system operation server 4, remote control computer Ⅰ5, remote control computer Ⅱ6, remote control computer Ⅲ7, centralized control system storage server 8 It consists of central switch 9, emergency stop PLC master station 10, emergency stop PLC slave station I11, emergency stop PLC slave station II12, emergency stop PLC slave station III13, emergency stop button I14, emergency stop button II15, and emergency stop button III16. All test equipment industrial computers, remote control computers and servers in the system are connected through the central switch 9 to realize free matching of any remote control computer to any test equipment. The remote control computers 5, 6, and 7 are equipped with ...

Embodiment 2

[0050] Example 2. A network-based remote centralized control system for turboshaft turboprop engine mechanical hydraulic product test equipment, which consists of Figure 1-3 shown, including:

[0051] The industrial control module of the test equipment is used to execute the test steps of the automated process documents;

[0052] Centralized control system operation server for system operation management;

[0053] The remote control module is used to compile the automation process file and send the command to execute the automation process file after logging in the centralized control system operation server;

[0054] The remote emergency stop button is used to realize the remote emergency stop of the test industrial control module;

[0055] The central switch is used for data interaction between the industrial control module of the test equipment, the operation server of the centralized control system and the remote control module;

[0056] The emergency stop PLC master ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com