Steel rail acoustic emission signal rapid high-precision reconstruction method based on compressed sensing

An acoustic emission signal, compressed sensing technology, applied in instruments, complex mathematical operations, calculations, etc., can solve the problems of poor real-time performance, low signal reconstruction accuracy, long reconstruction time, etc., to improve efficiency, improve dictionary performance, improve The effect of reconstruction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

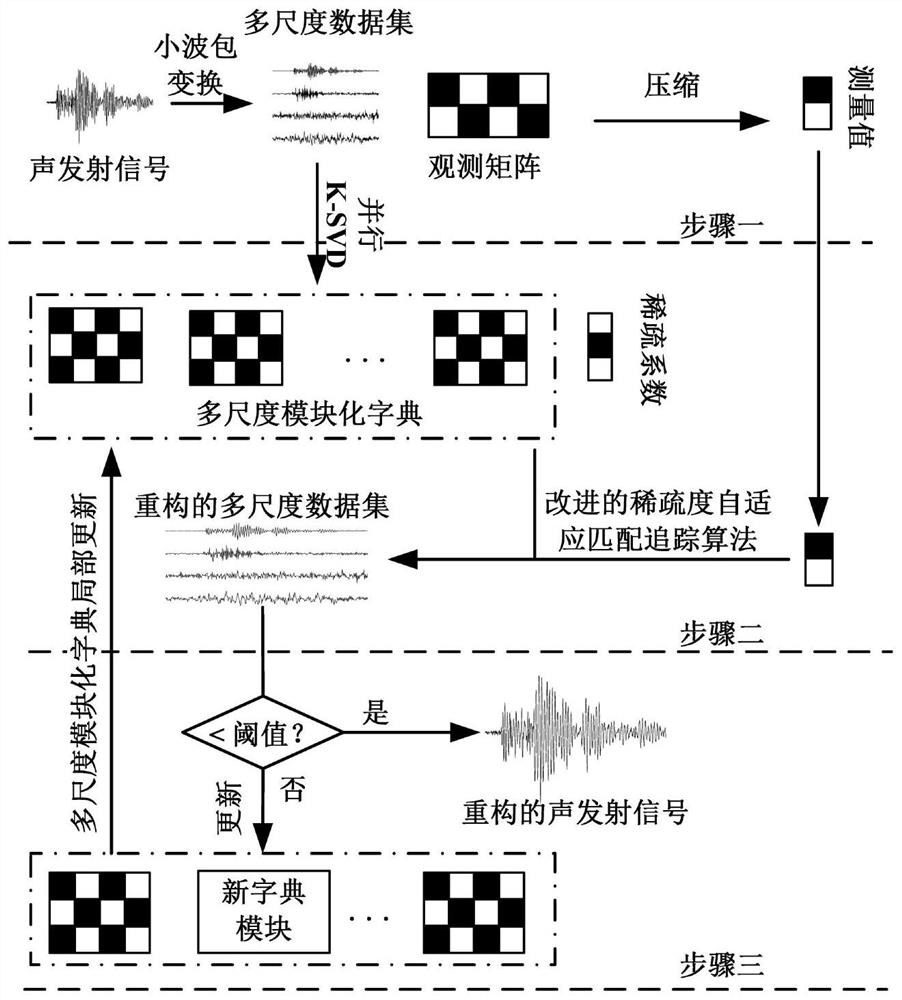

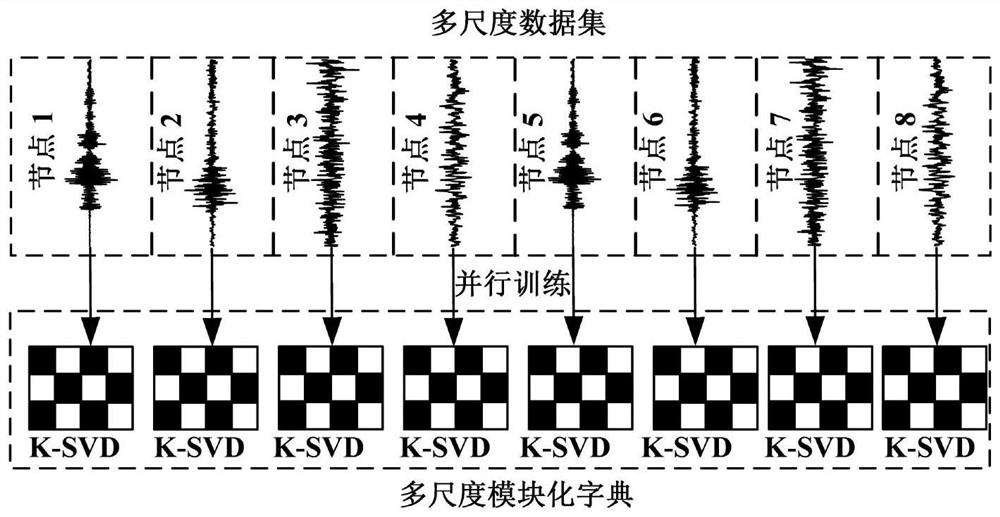

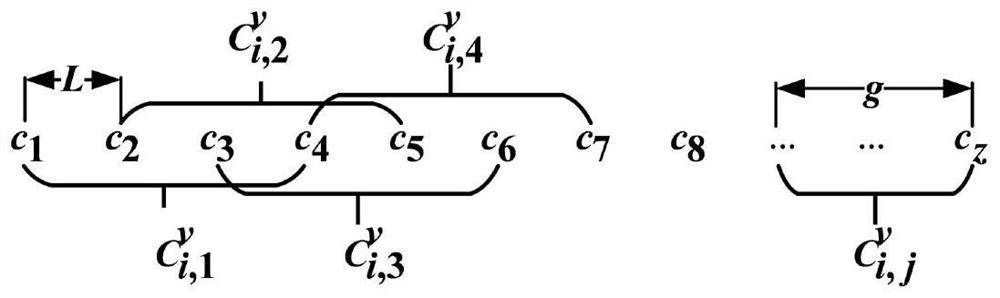

Method used

Image

Examples

specific Embodiment approach

[0105] The acoustic emission dataset was generated from tensile tests of rails in service. The rail tensile test is mainly composed of rail samples, Zwick Z100 tensile fracture machine and VallenAE signal acquisition system. Experimental equipment such as Figure 5shown. In the experiments, the specimens were made of U75V steel of the rails in use. A tensile machine is used to apply increasing tension to both ends of the rail specimen until the specimen breaks completely. During the tensile process of the rail sample, the material changes from the elastic stage to the plastic stage, and the crack of the sample gradually grows from initiation to expansion until it is completely broken. Among them, the acoustic emission signal is generated along with the crack growth. In the test, a Vallen VS900-RIC AE sensor and a VallenAMSY-6ASIP-2 / A acquisition system were used to continuously acquire signals. In addition, due to the high frequency band of the track crack signal, the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com