Automatic current applying method for composite copper foil equipment

A technology of composite copper foil and current application, applied in the direction of sustainable manufacturing/processing, parallel operation of DC power supply, climate sustainability, etc., can solve the problems of long time consumption, film breakage, fluctuations, etc. The effect of staff workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

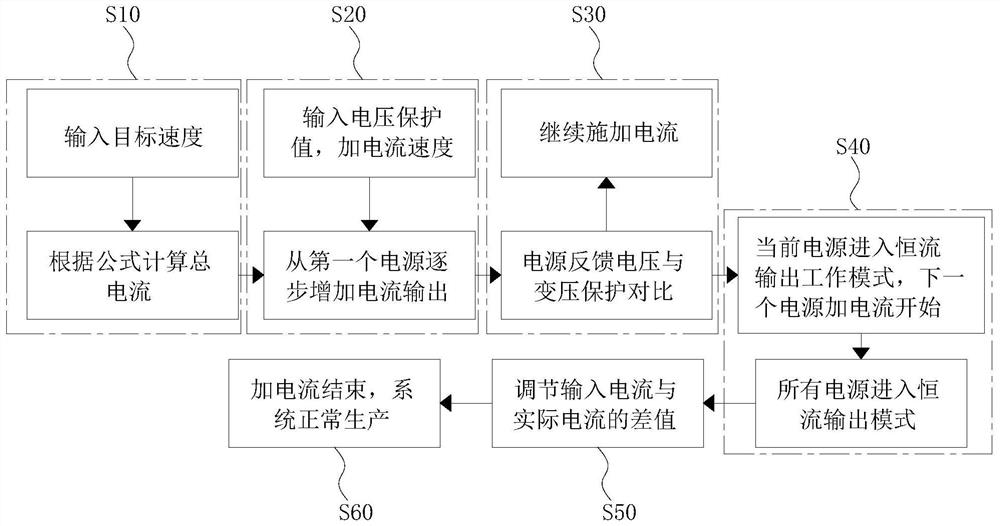

[0027] refer to figure 1 As shown, the present invention discloses an automatic current application method for composite copper foil equipment, which changes the manual current application method in the continuous coating process to the automatic current application method, and realizes the automatic sharing of the total current output by each power supply. Specifically, the method includes the following steps:

[0028] S10, calculating the total current, determining the line speed of the composite copper film operation, and calculating the total current to be applied by the entire copper plating production line;

[0029] In the production process of acid electroplating copper with composite conductive film, the current applied to the entire line can be calculated according to the empirical formula for each copper layer plated with a thickness of one micron. The total current I = constant N * line speed * product width, in In the segmental continuous coating process, the high...

Embodiment 2

[0042] refer to figure 1 As shown, the present invention discloses an automatic current application method for composite copper foil equipment, which changes the manual current application method in the continuous coating process to the automatic current application method, and realizes the automatic sharing of the total current output by each power supply. Specifically, the method includes the following steps:

[0043] S10, calculating the total current, determining the line speed of the composite copper film operation, and calculating the total current to be applied by the entire copper plating production line;

[0044] In the production process of acid electroplating copper with composite conductive film, the current applied to the entire line can be calculated according to the empirical formula for each copper layer plated with a thickness of one micron. The total current I = constant N * line speed * product width, in In the segmental continuous coating process, the high...

Embodiment 3

[0056] The present invention also provides an embodiment, and the difference between this embodiment and the above two embodiments is only in step S50 and the value of the constant N, the constant N of this embodiment is 1.5, in this embodiment, the step The content of S50 is as follows:

[0057] S50, adjusting the difference between the input current and the actual current;

[0058] If the applied current is greater than the calculated total current, the power supply of the whole line will reduce the current in order from back to front, and the minimum value allowed to be reduced can be set to reduce the current, so that the current output of each power supply will gradually decrease, and finally reach the actual applied current. The current reaches the calculated total current.

[0059] In addition, it should be noted that, in this embodiment, step S50 can be replaced by:

[0060] S50, adjusting the difference between the input current and the actual current;

[0061] If ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com