Efficient extraction device for oil-containing wastewater grease in sewage treatment

A sewage treatment and extraction device technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of serious secondary pollution, long treatment time, poor working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

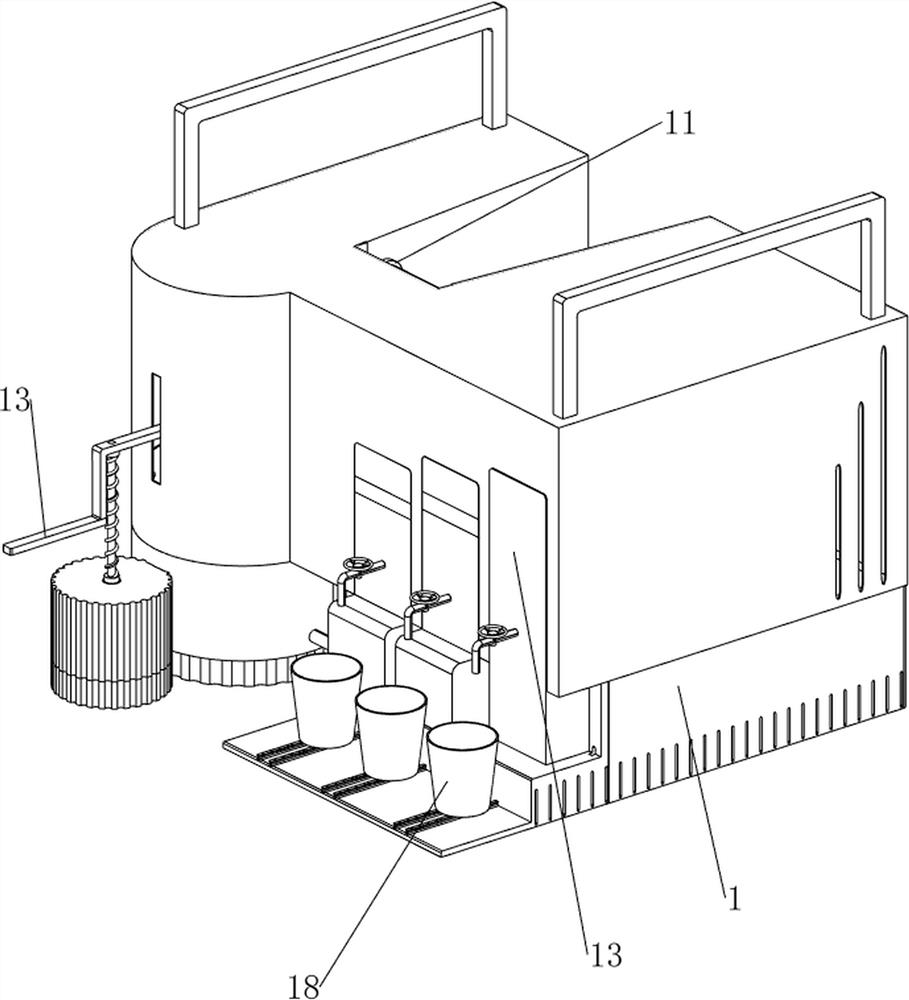

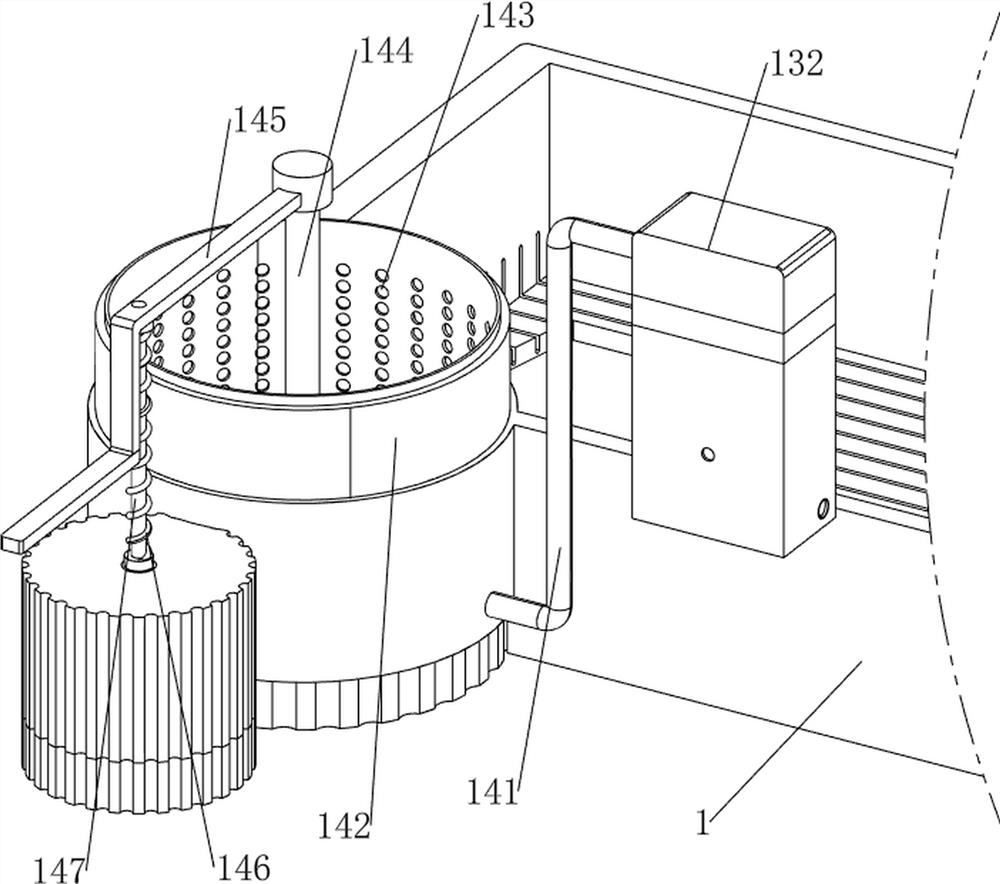

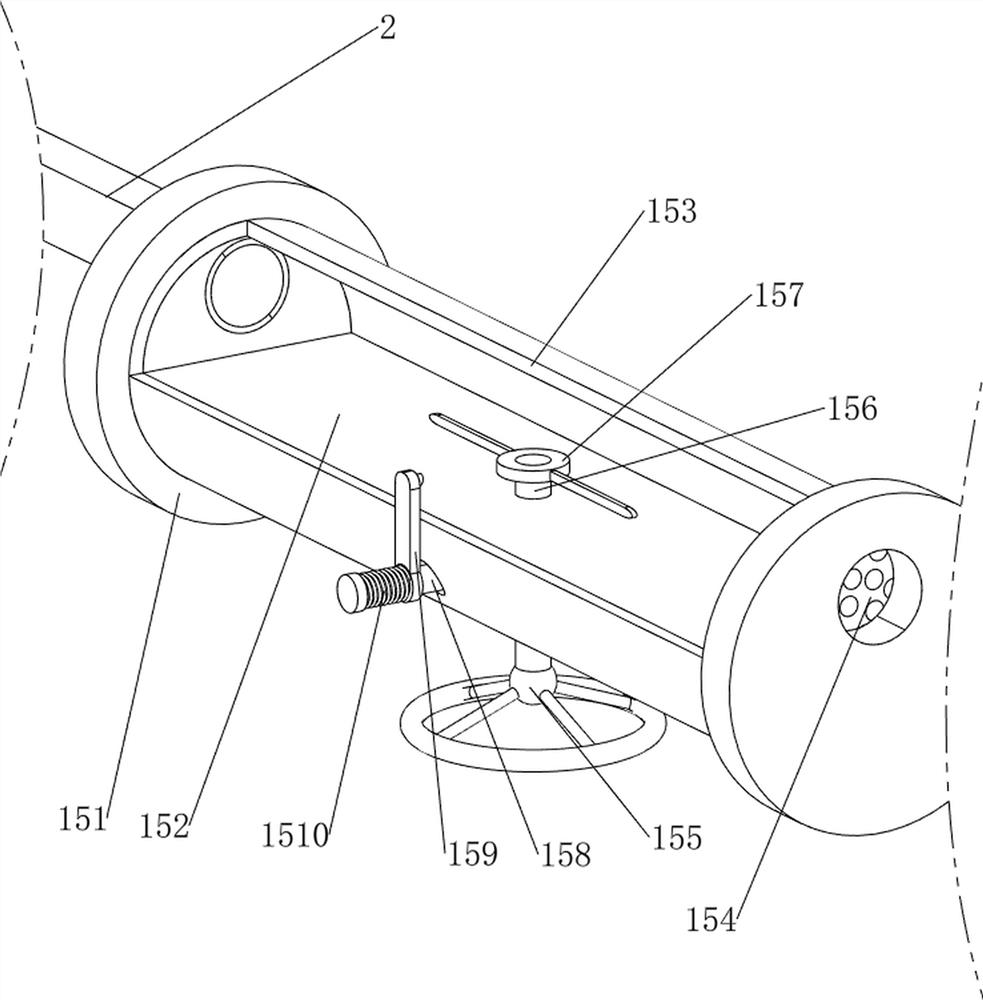

Embodiment 1

[0090] Sewage treatment of oil-containing wastewater oil high efficiency extraction device, such as Figure 1-7 As shown, including a box body 1, a first air circular tube 2, an elliptical precipitate box 3, a first fixing post 4, a first rotating shaft 5, a rotating water wheel 6, a belt 7, a second axis 8, a second fixed column 9 , The bevel gear 10, the third rotating shaft 11, the first two leaf turntable 12, the separation mechanism 13, the solidification mechanism 14, and the filter mechanism 15, the outermost portion of the casing 1 is provided with a first fixed post 4, the first fixed column The upper portion is provided with an elliptical precipitate box 3, and the upper side of the elliptical precipitate box 3 and the upper left wall of the casing 1 are provided with the first air circular tube 2, and the bottom portion of the elliptical precipitate box 3 is rotated between the bottom of the first fixed column 4. The third rotating shaft 11 is provided, and the second fi...

Embodiment 2

[0099] On the basis of Example 1, such as figure 1 , figure 2 , Figure 8 , Figure 9 and Figure 10As shown, it is also included, and a wiper material 16 is further included, the wiper material 16 includes a first connecting rod 161, a fourth fixed post 162, a second connecting rod 163, a fifth fixing post 164, a fifth axis 165, a motor 166, and The six-fixing column 167, the rotary turntable 168, the seventh fixing post 169, the slide jacket 1610, the third spring 1611 and the eighth fixing post 1612, the rear end of the pressure rod 145 is provided with a first connecting rod 161, and the bottom left center of the casing 1 The fifth fixation column 164 is provided, and a second connecting rod 163 is provided with a second connection rod 163. The second connection rod 163 is provided with a fourth fixed post 162, and the top end of the fourth fixed post 162 is connected to the first connection. The rod 161 is connected, and the upper portion of the fifth fixing post 164 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com