Foamed aluminum production line based on blowing foaming

A technology of blowing and foaming aluminum foam, which is applied in the field of aluminum foam production, can solve the problems of aluminum liquid addition control, manual work, and high heat loss, and achieve the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

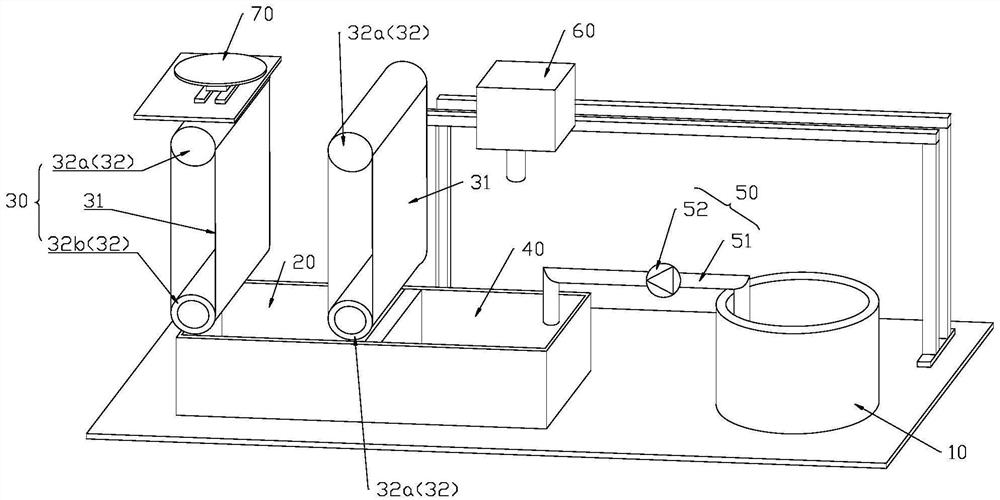

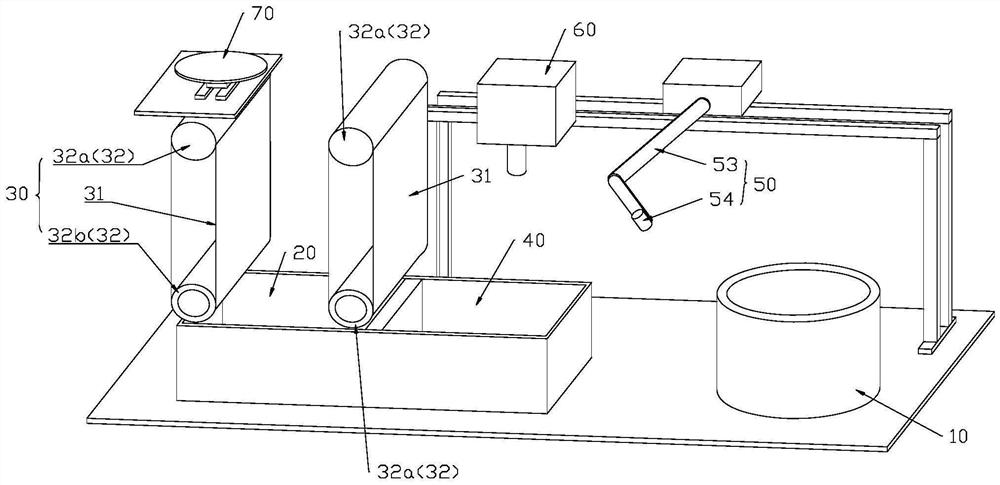

[0042] In the present invention, the function of the vertical cooling and pulling device 30 is to pull the generated aluminum liquid foam upwards, and cool it to make it solidify. As a specific implementation of the vertical cooling and pulling device 30, the The vertical cooling and pulling device 30 includes two conveyor belts 31 spaced in parallel and extending vertically. The conveyor belts 31 are made of thin steel plates or stainless steel wire mesh. Each conveyor belt 31 is stretched by conveyor rollers 32 positioned at its upper and lower ends. tight;

[0043] The first conveying roller 32a located at the upper end of the conveying belt 31 is in transmission connection with the driving unit, and the driving unit can drive the first conveying roller 32a to rotate and drive the conveying belt 31 to convey the molten aluminum foam upward;

[0044] The second conveying roller 32b located at the lower end of the conveying belt 31 is designed as a hollow structure, and a cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com