Wet and soft soil foundation self-drainage dynamic compaction treatment method and self-drainage dynamic compaction equipment

A technology for foundation treatment and dynamic compaction equipment, applied in soil protection, infrastructure engineering, construction, etc., can solve problems affecting construction efficiency, and achieve the effect of improving construction efficiency and construction quality, and optimizing water level control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

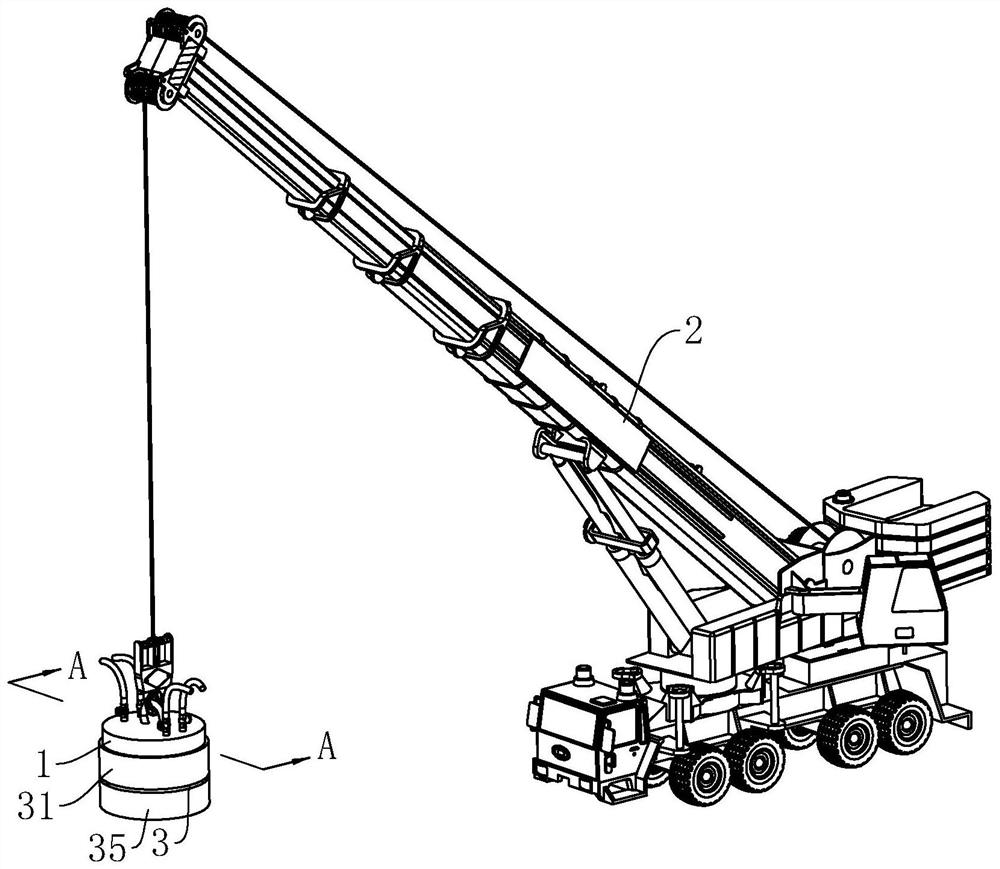

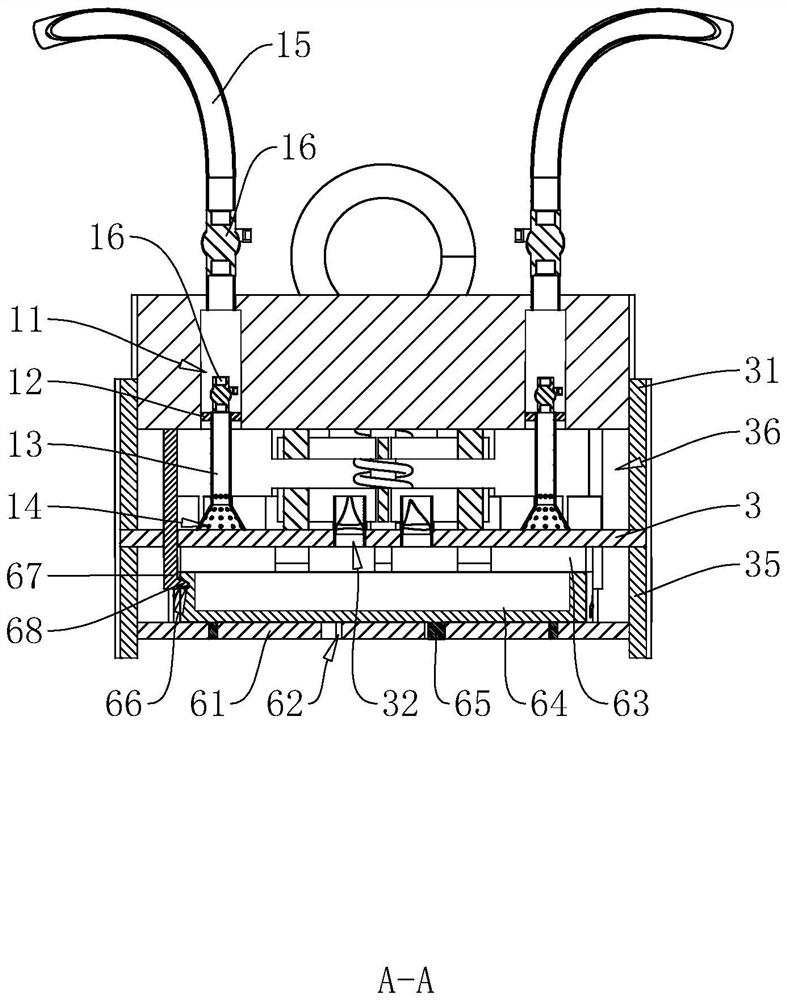

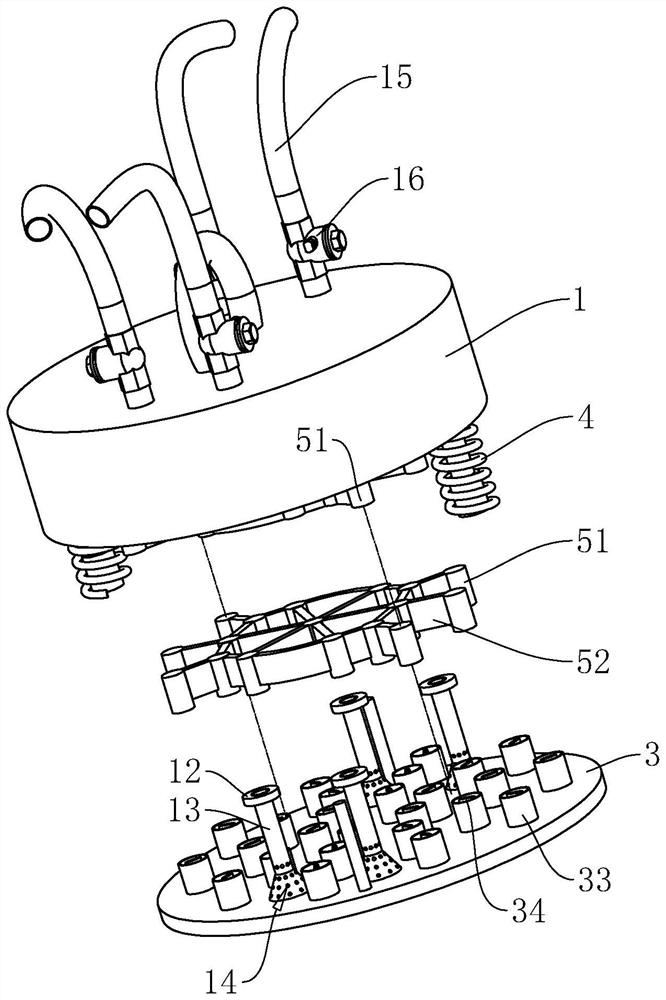

[0050] Contraction below Figure 1-5 Further detailed description of the present application.

[0051] The present application discloses a self-discharged power of a wet soft soil treatment. Refer figure 1 and figure 2 , The self-drainage power of the wet soft soil, including a hammer 1, a lifting device 2 for lifting the hammer 1, wherein the lifting device 2 can be a hiking machine, a hoisting machine or a crane, a tamper 1 is cylindrical; The bottom interval between the hammer 1 is provided with a hobby plate 3, and the hobby plate 3 is also a circular plate shape, and the hobby plate 3 is connected between the hit plate 3 and the hammer 1, and the elastic reset member 4 is provided with a plurality of and set as a spring. Further, in the middle of the elastic reset member 4, a telescopic rod can also be laid, and the telescopic rod is fastened to the bottom wall of the hammer 1, and the other end is solid to the hobby plate 3. At the same time, the sniper plate 3 is fixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com