Special-shaped H-shaped steel beam suitable for pitched roof ridge and connecting joint and construction method of special-shaped H-shaped steel beam

A technology of H-shaped steel and sloping roofs, which is applied in the direction of roofs, joists, girders, etc., which can solve the problems of difficulty in laying roof panels, environmental protection, unfavorable roof panel laying, etc., and achieve light weight, easy assembly, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

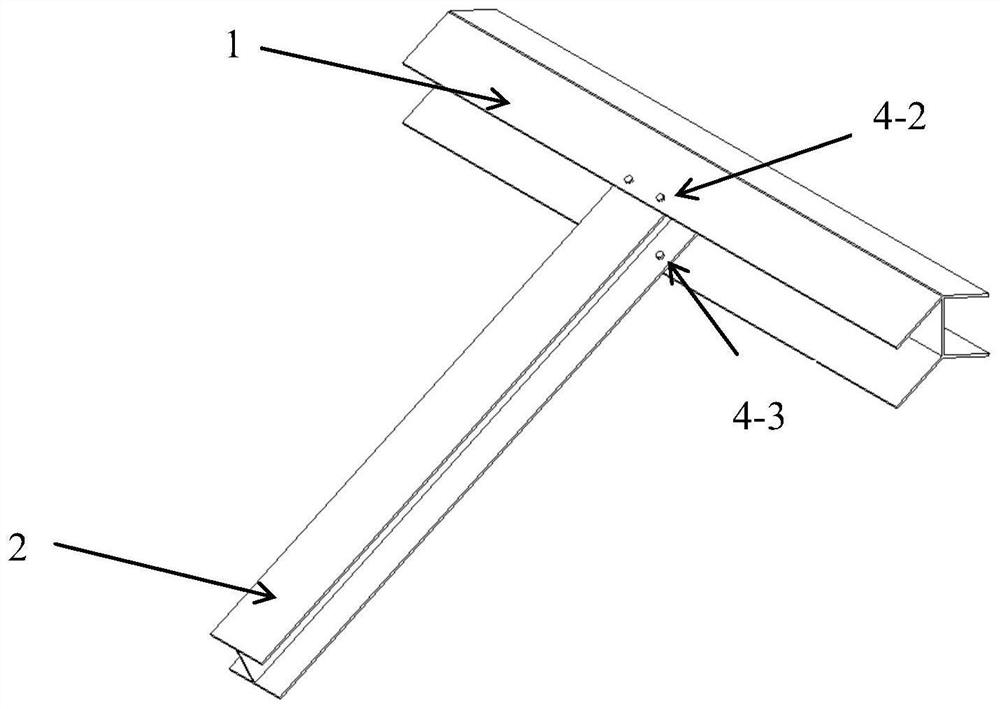

[0020] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

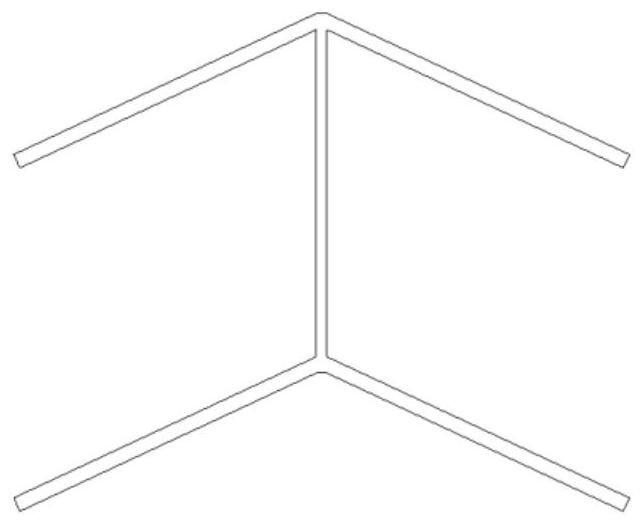

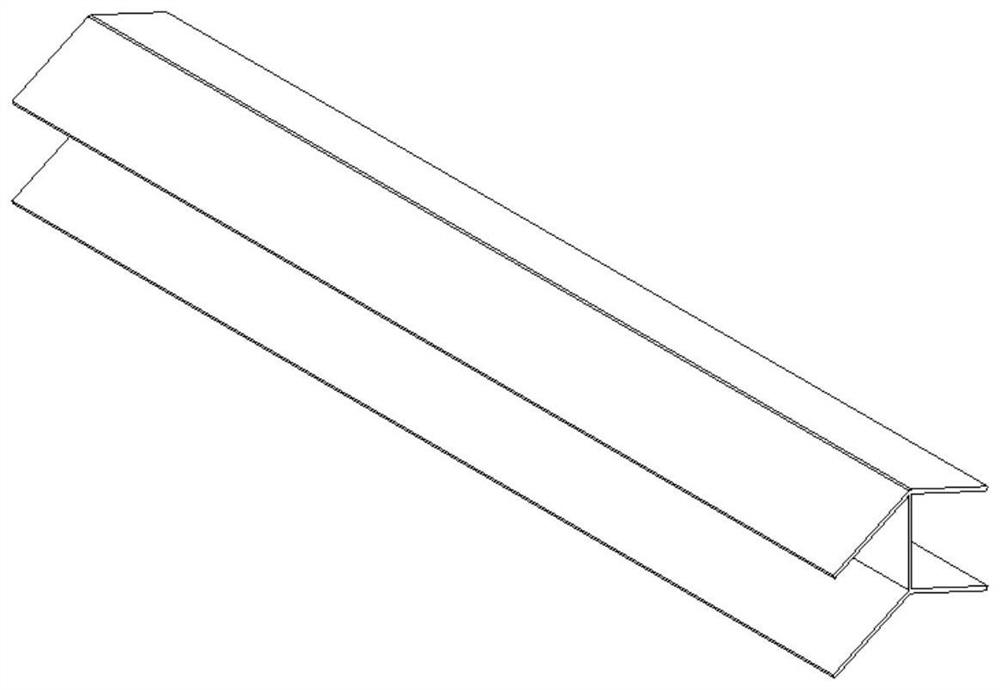

[0021] see Figure 1 to Figure 2 , a special-shaped H-shaped steel beam suitable for the ridge of the sloping roof, the special-shaped H-shaped steel beam 1 is made of cold-formed thin-walled special-shaped H-shaped steel, and the upper and lower flanges of the special-shaped H-shaped steel are provided with The inclination angle that matches the start angle.

[0022] When the starting angles of the front and rear slopes of the pitched roof are the same, the cross-section of the special-shaped H-shaped steel beam 1 is axisymmetric about the center line of the web.

[0023] In this embodiment, the special-shaped H-shaped steel beam 1 has a web thickness of 2-5mm and a flange thickness of 2-5mm, and is light in weight. When in use, it can be transported an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com