Underground rock clear oil drying system capable of collecting heat through double-pipe-groove type solar energy and using method of underground rock clear oil drying system

A technology of solar heat collection and solar heat collector, which is applied in the direction of solar heating system, solar heat collector, solar heat collector safety, etc., can solve the problems of non-energy saving, prolong service life, ensure safety, and increase life span Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

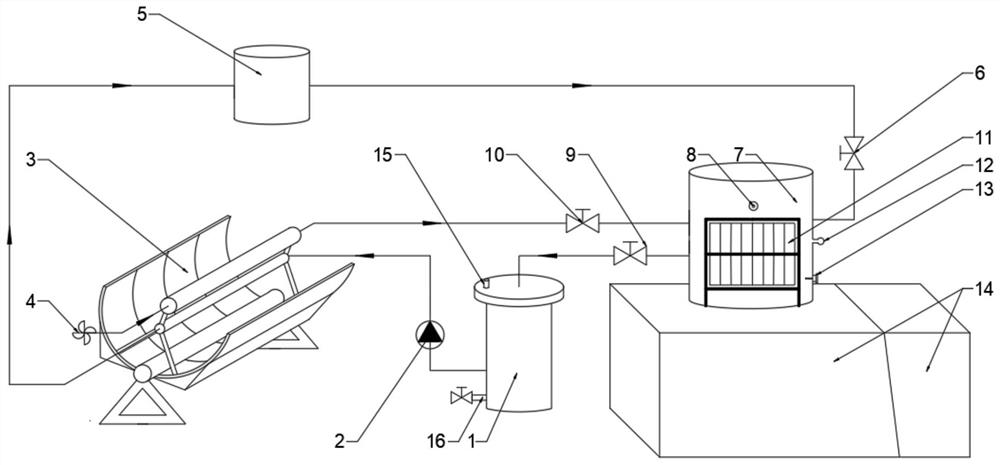

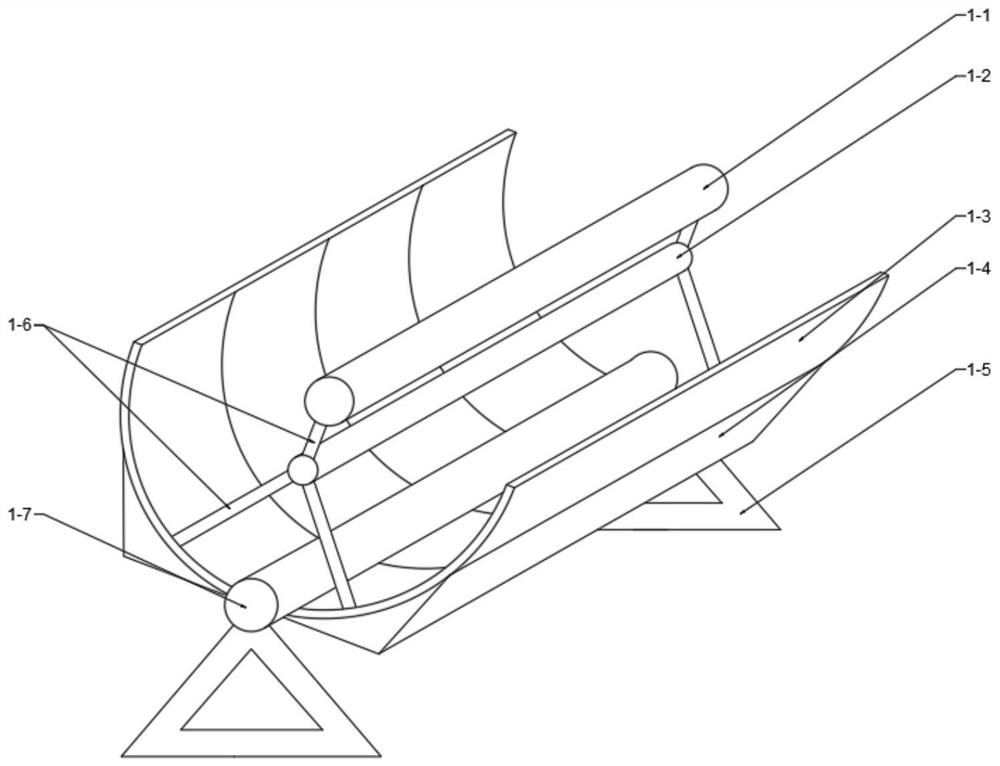

[0029] With reference to the accompanying drawings, a further description will be made of a double-pipe trough type solar heat collecting system for clearing oil and drying underground rock formations.

[0030] Such as figure 1 As shown, the present invention provides a system for clearing oil and drying underground rock formations with double-pipe trough solar heat collection, comprising an organic solvent storage chamber 1, and the bottom of the side wall of the organic solvent liquid storage chamber 1 is sequentially connected with a double-pipe trough solar collector. The second heat collecting tube 1-2 of the heater 3, the condensation chamber 5 and the material cleaning box 7, the blower fan 4 are connected with the double-pipe trough type solar heat collector 3, and the material cleaning box 7 successively. In this embodiment, the organic solvent storage The liquid chamber 1 is connected to the inlet of the second heat collecting tube 1-2 of the double-pipe trough solar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com