Control method of refrigerator

A control method and refrigerator technology, which are applied in household refrigerators, ice making, refrigerators, etc., can solve the problems of large air supply resistance and cooling loss, extremely high flow accuracy requirements, and aesthetic discounts, etc., and achieve reduced size. / Volume, good control consistency, and the effect of improving the cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

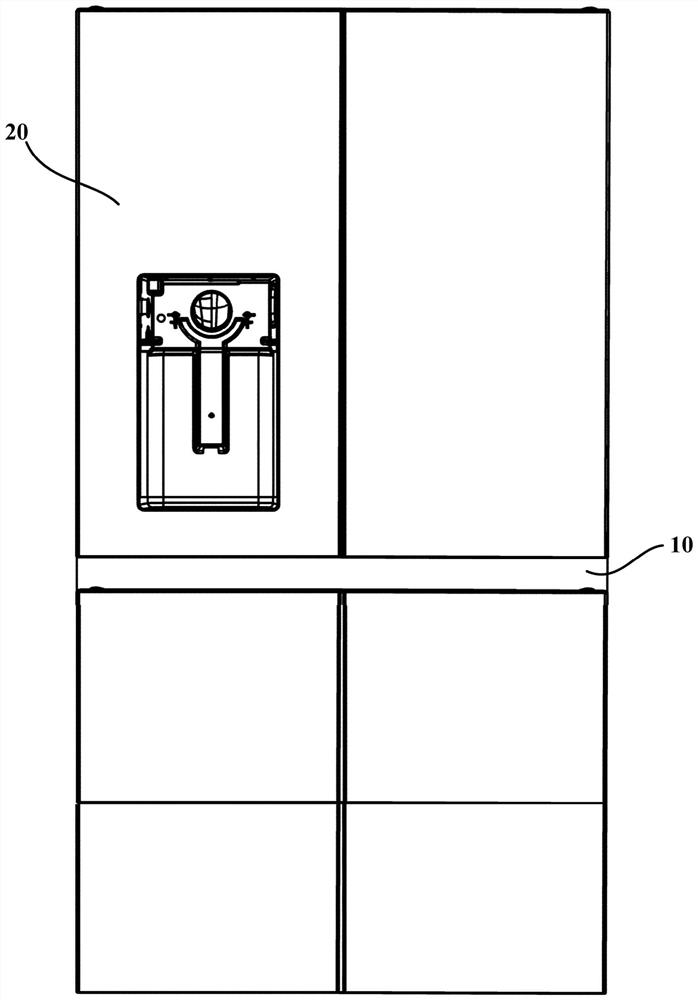

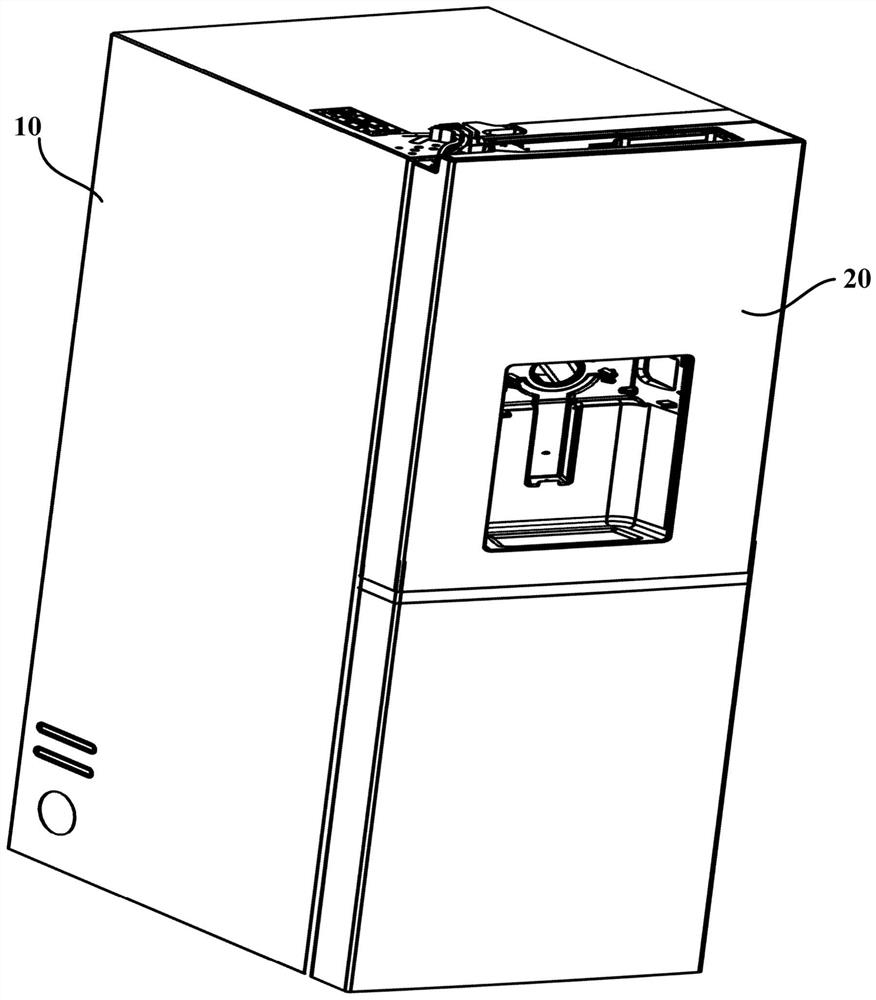

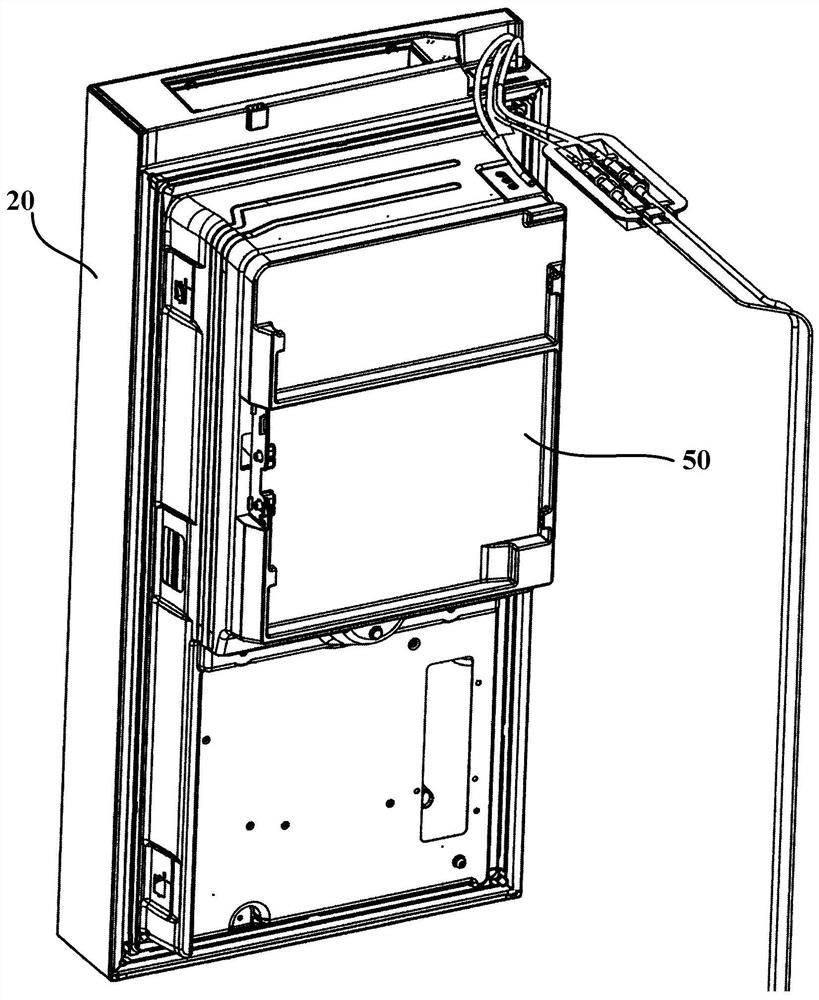

[0039] figure 1 is a schematic structural diagram of a refrigerator according to an embodiment of the present invention. Such as figure 1 shown and refer to Figure 2 to Figure 7 , The embodiment of the present invention provides a refrigerator. The refrigerator includes a box body 10, a door body 20 and a refrigeration system. The box body 10 is provided with storage compartments, such as a first storage compartment, a second storage compartment and a third storage compartment. The first storage compartment may be a refrigerated compartment, and the storage temperature is generally between 2°C and 10°C, preferably between 3°C and 8°C. The second storage compartment can be a freezer compartment, and the temperature range is generally -14°C to -22°C. The third storage compartment can be a temperature-changing compartment, and the temperature inside it can be adjusted according to demand, so as to store suitable food. The door 20 is configured to open and close the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com