Submerged-arc welding molten drop collection and arc plasma characterization device and method

A technology of arc plasma and submerged arc welding, which is applied in the field of submerged arc welding to achieve the effect of in-situ spectral analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

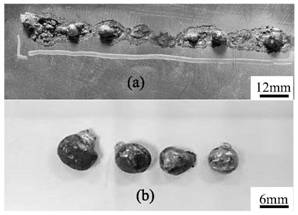

Examples

Embodiment 1

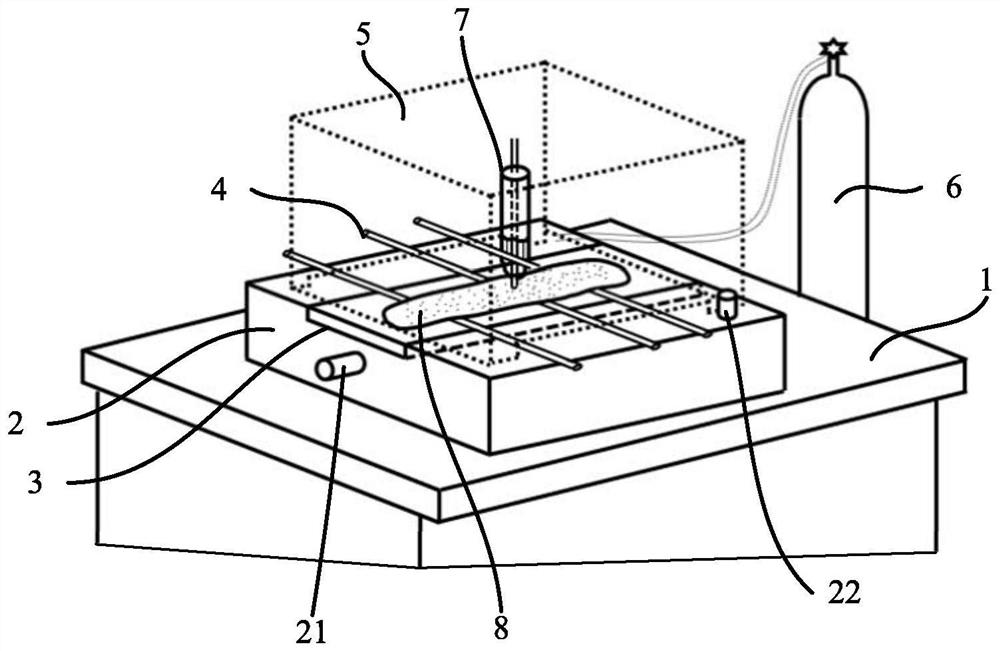

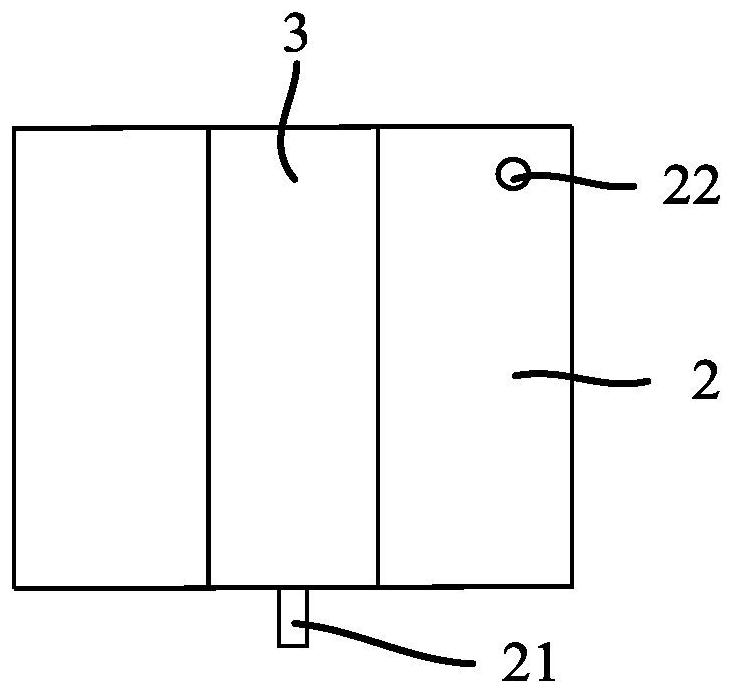

[0046] see figure 1 with figure 2 As shown, the embodiment of the present application provides a device for submerged arc welding droplet collection and arc plasma characterization, including: a translation mechanism 1, a cooling component 2, a metal conductive component 3 and a plurality of spectral signal guiding components 4;

[0047] Wherein, the cooling member 2 is arranged on the translation mechanism 1, the metal conductive member 3 is arranged on the cooling member 2, and the translation mechanism 1 is used to drive the cooling member 2 to move along the welding direction;

[0048] A plurality of spectral signal guiding members 4 are all arranged on the metal conductive member 3 , and are sequentially arranged at intervals along the length direction of the metal conductive member 3 ; the spectral signal guiding member 4 is formed with a conduction channel.

[0049] According to the structure described above, it can be seen that the use process of the device for subme...

Embodiment 2

[0081] Embodiment 2 of the present application also provides a method for submerged arc welding droplet collection and arc plasma characterization, based on the device for submerged arc welding droplet collection and arc plasma characterization described in Embodiment 1 above, and thus, has the All the beneficial technical effects of the device for submerged arc welding droplet collection and arc plasma characterization, the same technical features and beneficial effects will not be repeated.

[0082] In this embodiment, preferably, as figure 1 As shown, the method for submerged arc welding droplet collection and arc plasma characterization includes the following steps:

[0083] Place solder 8 on the metal conductive member 3, and the solder 8 extends along the length direction of the metal conductive member 3;

[0084] Place the conductive tip 7 of the welding machine above the flux 8;

[0085]Start the welding machine, and use the translation mechanism 1 to drive the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com