PERC battery piece back electrode silver paste suitable for high-temperature sintering and preparation method of PERC battery piece back electrode silver paste

A high-temperature sintering, back electrode technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

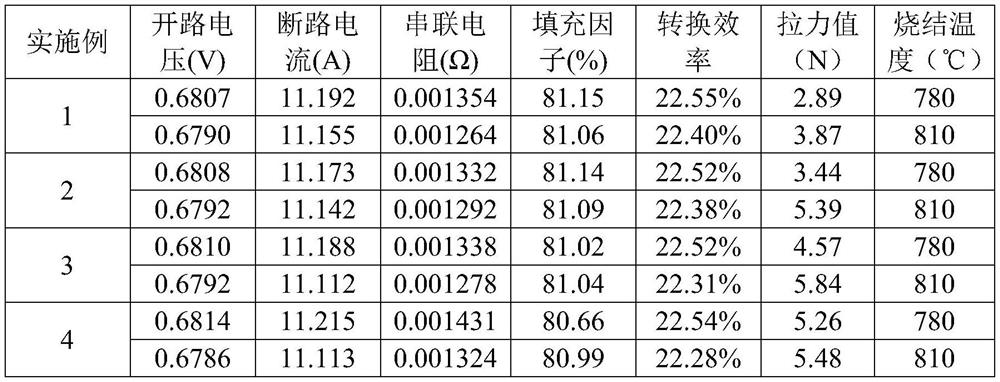

Embodiment 1

[0038] A silver paste suitable for high-temperature sintering PERC cell back electrode, the composition is as follows by weight percentage:

[0039] Spherical silver powder 65.4%, glass powder A 1.1%, glass powder B 0.5%, organic vehicle 33.0%.

[0040] Among them, the spherical silver powder has a particle size D10 of 0.5-1.5 μm, a D50 of 1.0-2.0 μm, a D90 of 2.0-3.0 μm, and a tap density of 3.5-5.5 g / cm by a laser particle size distribution analyzer. 3 ; Specific surface area 1.0-2.0m 2 / g.

[0041] The softening point of glass powder A is 650-750°C, and the composition is as follows in parts by weight: Bi 55%; Si 10%; Ti 5%; B 3%; Mg 10%; Ag 2%; Ca 15%; glass powder B The softening point is 450-600°C, and the composition is as follows in parts by weight: Pb 45%, Bi 15%, Si 15%, Ti 5%, Cu 6%, Mn 14%.

[0042]The preparation method of glass powder A is as follows: mix the components of glass powder A evenly, bake at 1400°C until the glass liquid is clear and transparent, t...

Embodiment 2

[0048] A silver paste suitable for high-temperature sintering of the back electrode of the PERC cell, which is the same as in Example 1, except that the glass powder A is 0.9%, and the glass powder B is 0.7%.

[0049] The preparation method of the back electrode silver paste is the same as in Example 1.

Embodiment 3

[0051] A silver paste suitable for high-temperature sintering of the back electrode of PERC cells, which is the same as that in Example 1, except that the glass powder A is 0.7%, and the glass powder B is 0.9%.

[0052] The preparation method of the back electrode silver paste is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com