Lead positioning device for processing organic thin-film capacitor and assembling method

A capacitor processing, organic thin film technology, applied in the direction of thin film/thick film capacitors, fixed capacitor terminals, fixed capacitor shell/package, etc. Improve potting quality, shorten production cycle, avoid potting interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings:

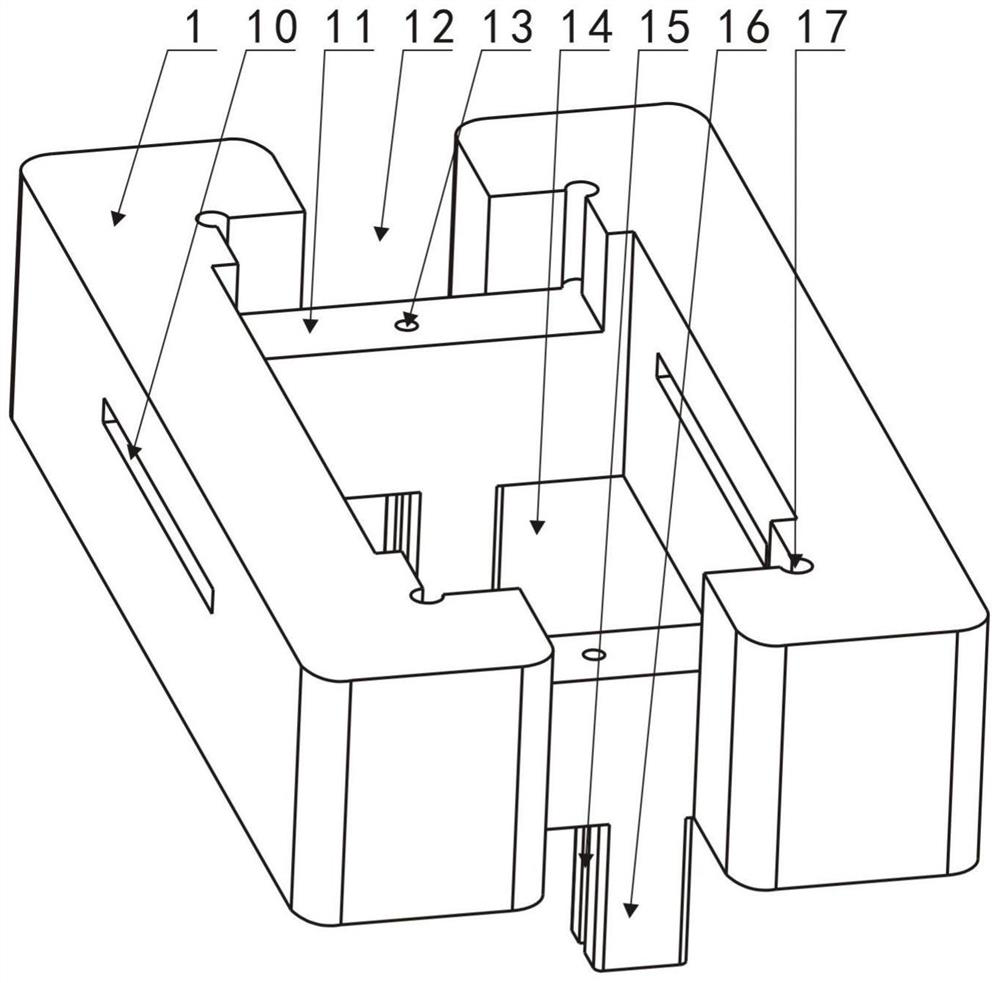

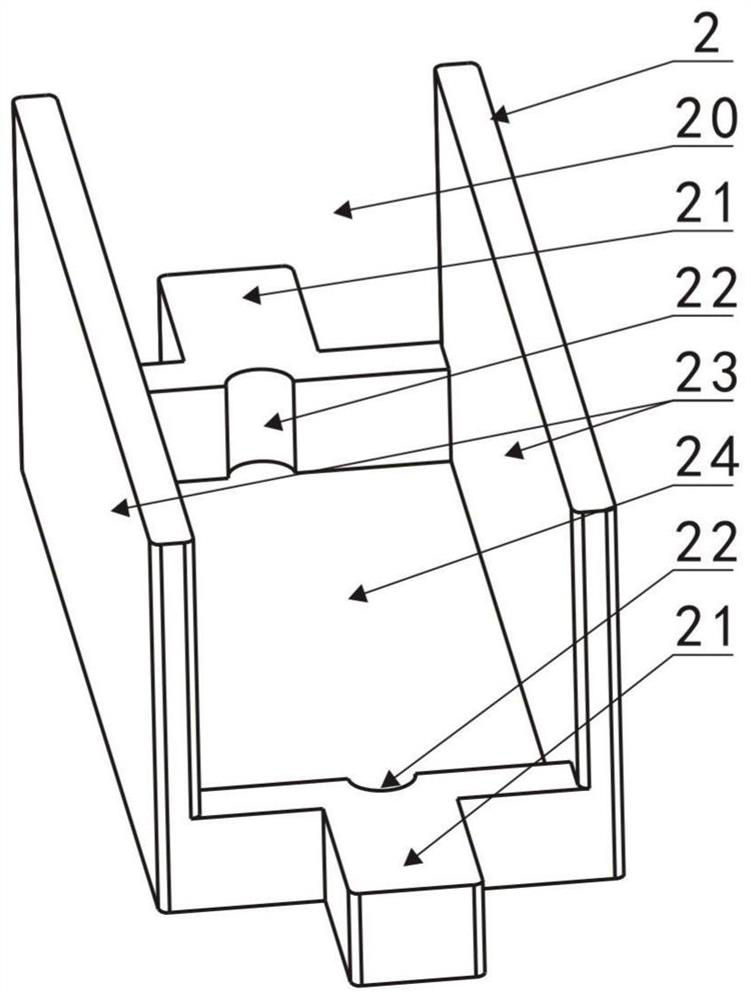

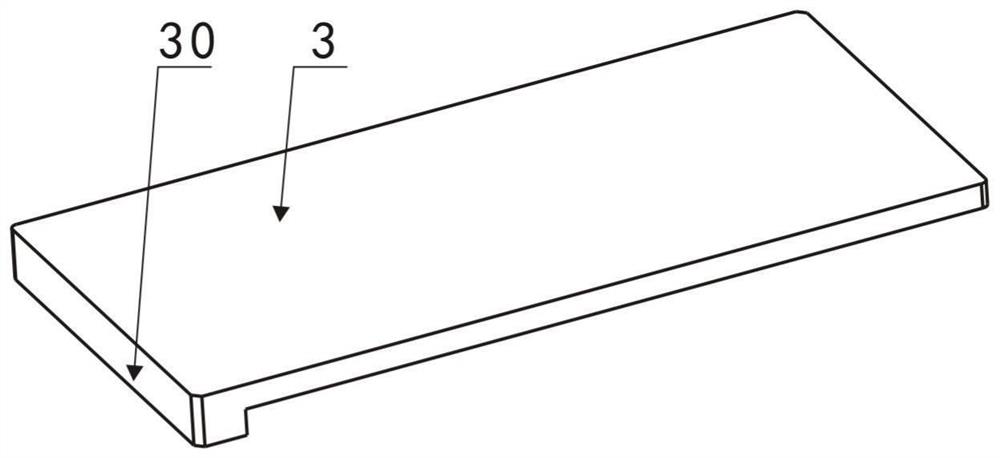

[0043] Such as Figure 1 - Figure 5 As shown, the organic thin film capacitor of the present invention includes a capacitor housing 6, a capacitor core set 4, and a lead 5, the lead positioning device for the organic thin film capacitor processing includes a first positioning tool body 1, a second positioning The tooling body 2 and the positioning tablet 3, the first positioning tool body 1 is a rectangular shape and is provided in the longitudinal direction of the lateral direction to be X-direction, the lateral direction is Y, the first positioning tool body 1 is provided with a first vertical In the through hole 14, the first positioning tool body 1 is located at a position other than the X to both ends of the first vertical via hole 14, and the two sub-sink platform 11 are commonly formed for mounting capacitor. The housing mounting space of the outer casing 6 (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com