Enhanced thixotropic lubricant and gypsum mortar containing same

A technology of thixotropic lubricant and gypsum mortar, which is applied in the field of building materials, can solve the problems of low strength of gypsum mortar and large water consumption, and achieve good ash leveling, large thixotropy, good flexural and compressive properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

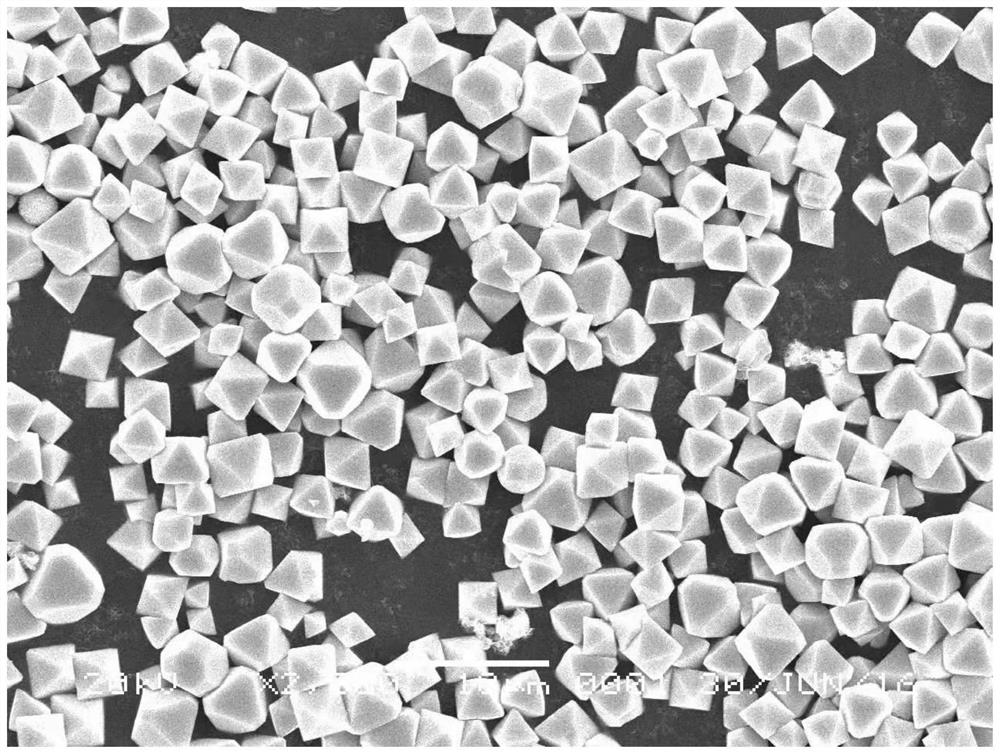

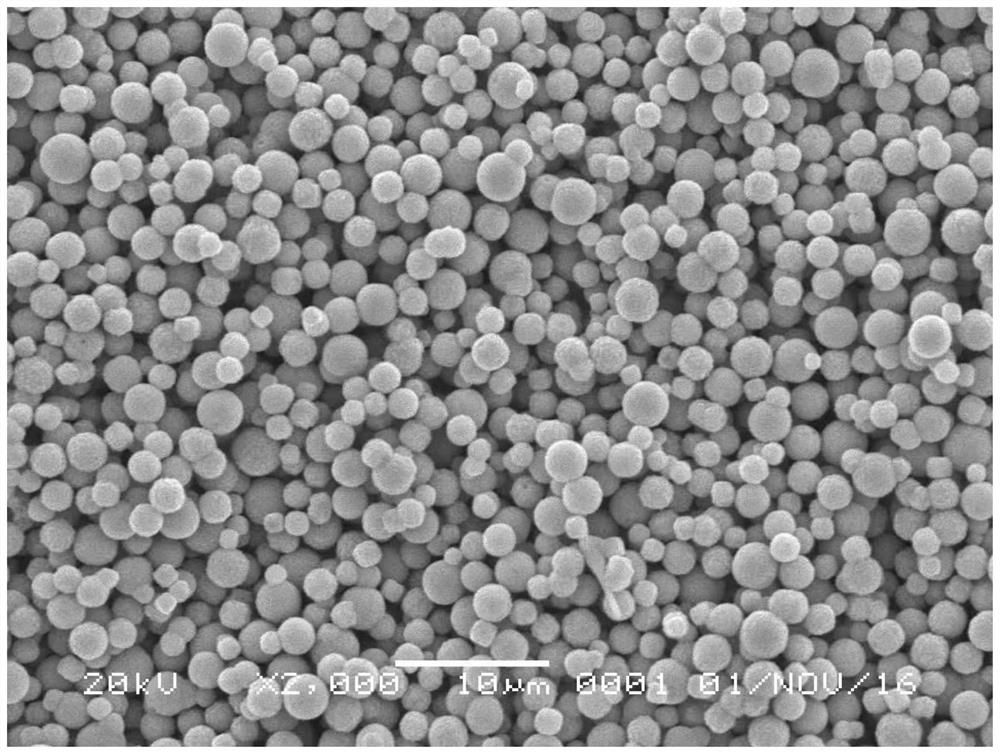

Image

Examples

Embodiment 1

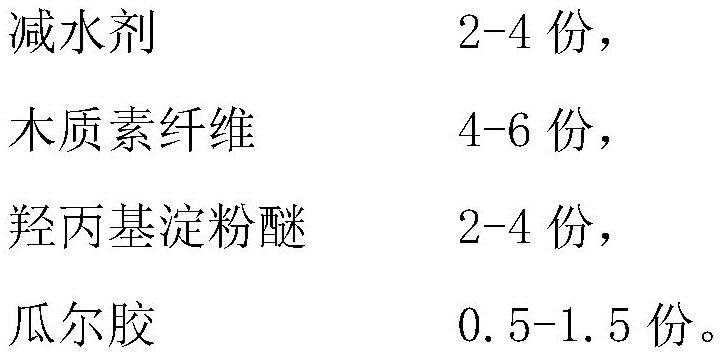

[0029] 3 parts of sodium melamine formaldehyde resin sulfonate, 5 parts of lignin fiber, 3 parts of hydroxypropyl starch ether, and 1 part of guar gum are uniformly stirred to obtain a finished gypsum-enhanced thixotropic lubricant.

Embodiment 2

[0031] 2 parts of sodium melamine formaldehyde resin sulfonate, 4 parts of lignin fiber, 2 parts of hydroxypropyl starch ether, and 0.5 part of guar gum are evenly stirred to obtain a finished gypsum-enhanced thixotropic lubricant.

Embodiment 3

[0033] 4 parts of sodium melamine formaldehyde resin sulfonate, 6 parts of lignin fiber, 4 parts of hydroxypropyl starch ether, and 1.5 parts of guar gum are uniformly stirred to obtain a finished gypsum-enhanced thixotropic lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com