Stalk wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite material and straw, which is applied in the field of straw-wood-plastic composite material and its preparation, can solve the problem that the application of straw is not so common, achieve improved processing performance and mechanical properties, excellent mechanical properties, increase bending strength and Effect of Flexural Modulus of Elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

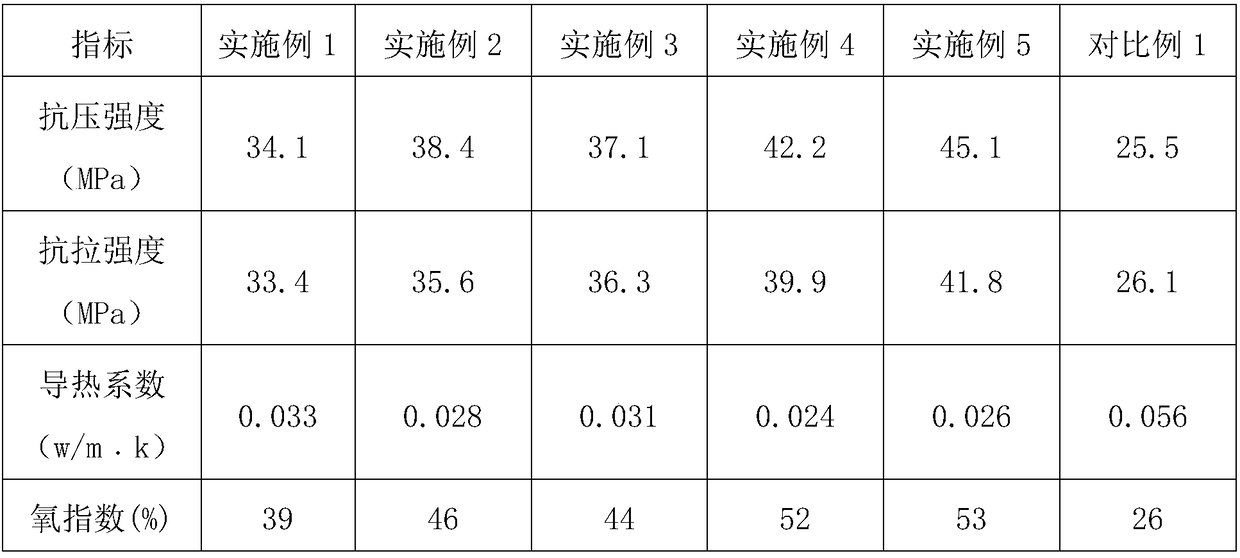

Examples

Embodiment 1

[0031] A straw wood-plastic composite material, comprising the following raw materials in parts by weight:

[0032] 25 parts of straw, 10 parts of sawdust, 30 parts of waste polyethylene foam, 3 parts of maleic anhydride grafted polyethylene, 5 parts of castor oil, 4 parts of activated carbon, 2 parts of graphite, 6 parts of bentonite, 5 parts of calcium carbonate, aromatic 1 part of fiber, 4 parts of feldspar powder, 2 parts of nano-zinc oxide, 1.2 parts of flame retardant, 0.4 part of foaming agent, and 0.7 part of antioxidant.

[0033] The foaming agent is composed of azodicarbonamide and sodium bicarbonate in a mass ratio of 4:1.

[0034] The flame retardant is decabromodiphenylethane.

[0035] The antioxidant is composed of polyolefin pentaerythritol ester, diphenyldecyl phosphite and phosphite in a mass ratio of 5:2:1.

[0036] The preparation method of the straw wood-plastic composite material in this embodiment specifically includes the following steps:

[0037] (1)...

Embodiment 2

[0046] A straw wood-plastic composite material, comprising the following raw materials in parts by weight:

[0047]35 parts of straw, 18 parts of sawdust, 40 parts of waste polyethylene foam, 7 parts of maleic anhydride grafted polyethylene, 10 parts of castor oil, 9 parts of activated carbon, 5 parts of graphite, 12 parts of bentonite, 10 parts of calcium carbonate, aromatic 4 parts of fiber, 9 parts of feldspar powder, 5 parts of nano-zinc oxide, 1.8 parts of flame retardant, 0.8 parts of foaming agent, and 1.5 parts of antioxidant.

[0048] The foaming agent is composed of azodicarbonamide and sodium bicarbonate in a mass ratio of 4:1.

[0049] The flame retardant is decabromodiphenyl ether.

[0050] The antioxidant is composed of polyolefin pentaerythritol ester, diphenyldecyl phosphite and phosphite in a mass ratio of 5:2:1.

[0051] The preparation method of the straw wood-plastic composite material in this embodiment specifically includes the following steps:

[0052...

Embodiment 3

[0061] A straw wood-plastic composite material, comprising the following raw materials in parts by weight:

[0062] 28 parts of straw, 13 parts of sawdust, 33 parts of waste polyethylene foam, 4 parts of maleic anhydride grafted polyethylene, 6 parts of castor oil, 5 parts of activated carbon, 3 parts of graphite, 8 parts of bentonite, 6 parts of calcium carbonate, aromatic 2 parts of fiber, 5 parts of feldspar powder, 3 parts of nano-zinc oxide, 1.4 parts of flame retardant, 0.5 parts of foaming agent, and 0.9 parts of antioxidant.

[0063] The foaming agent is composed of azodicarbonamide and sodium bicarbonate in a mass ratio of 4:1.

[0064] The flame retardant is melamine cyanurate.

[0065] The antioxidant is composed of polyolefin pentaerythritol ester, diphenyldecyl phosphite and phosphite in a mass ratio of 5:2:1.

[0066] The preparation method of the straw wood-plastic composite material in this embodiment specifically includes the following steps:

[0067] (1) W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com