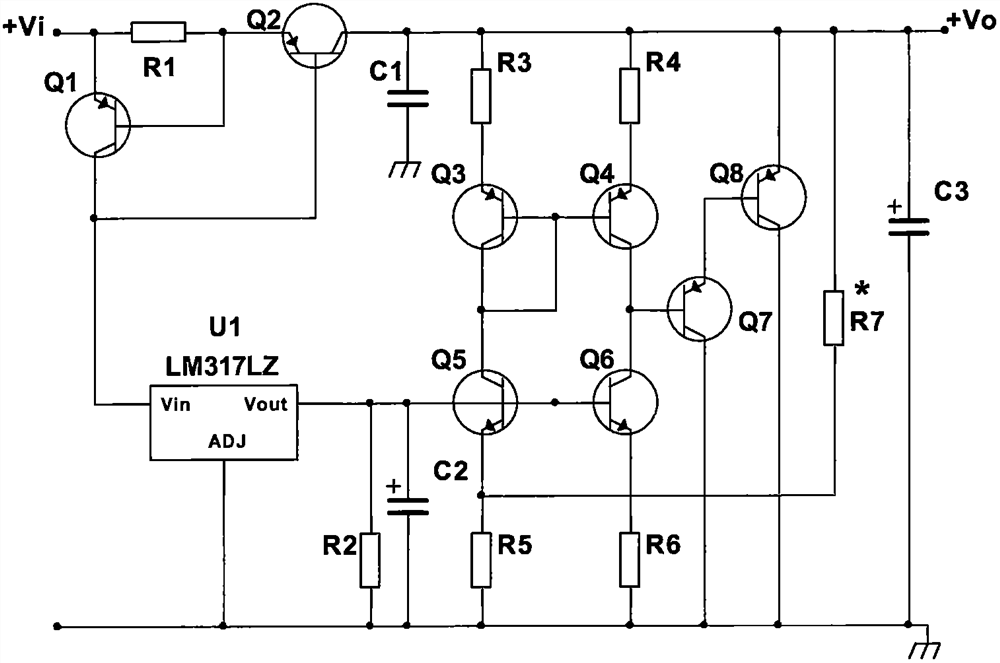

Power supply circuit with emitter current negative feedback

A technology of power supply circuit and negative feedback, which is applied in the direction of conversion equipment, electrical components, and adjustment of electrical variables without intermediate conversion to AC. It can solve the problems of low operating frequency and slow transmission speed of differential circuits, and achieve speed and frequency improvement. Solve the effect of time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] This circuit takes the Vi of the attached drawing as the input terminal, and its circuit connection method is: Vi→Q1 emitter, collector→U1 Vin terminal (ADJ grounded)→Vout terminal→R2 (the other terminal grounded)→Q5, Q6 base , Vi→R1→Q2 emitter, collector→R3→Q3 emitter, collector (collector→Q3, Q4 base)→Q5 collector, emitter→R5→ground, Q2 collector→R4→Q4 emitter Pole, collector→Q7 base→Q6 collector, emitter→R6→ground, Q2 collector→Q8 emitter, collector→ground, Q8 base→Q7 emitter, collector→ground, Q2 collector→ R7→R5 upper end. Q2 collector → Vo terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com