Non-grain type monogastric animal feed and preparation method thereof

An animal feed, non-grain technology, applied in the direction of animal feed, animal feed, animal feed molding or processing, etc., to achieve the effects of alleviating severe shortages, reducing energy consumption, and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

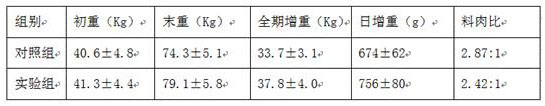

Examples

preparation example Construction

[0039] The preparation method of the non-grain type monogastric animal feed of the present invention is prepared by uniformly mixing the raw materials in the formula ratio.

[0040] The present invention will be further described below with specific implementation case:

Embodiment 1

[0042] raw material preparation

[0043] S1. Shade-dried ingot maple leaves are crushed and passed through a 60-mesh sieve;

[0044] S2. Shade-dried, sun-dried or dried leaf-eating grasses are pulverized and passed through a 60-mesh sieve;

[0045] S3. The dried Eupatorium adenophorum and grain amaranth were pulverized respectively, and passed through a 10mm sieve.

[0046] S4. Fill the crushed Eupatoria adenophorum into the steam explosion device, and explode it instantly after maintaining the pressure for 50 seconds under the pressure of 1.9MPa to obtain Eupatoria adenophorum with a removal rate of 98.9% of the toxic component Euptox A, and further dry it , crushed, and passed through a 60-mesh sieve.

[0047] S5. Fill the pulverized grain amaranth into the steam explosion device, and blast it instantly after maintaining the pressure for 70 seconds at a pressure of 1.8 MPa. The obtained grain amaranth is further dried, pulverized, and passed through a 60-mesh sieve.

[00...

Embodiment 2

[0050] raw material preparation

[0051] S1. Shade-dried Yuanbao maple leaves are crushed and passed through a 60-mesh sieve

[0052] S2. Shade-dried, sun-dried or dried leaf-eating grasses are crushed and passed through a 60-mesh sieve

[0053] S3. The dried Eupatorium adenophorum and grain amaranth are respectively pulverized and passed through a 10mm sieve.

[0054] S4. Fill the crushed Eupatorium adenophorum into the steam explosion device, and explode instantly after maintaining pressure for 20 seconds under a pressure of 3.0 MPa. Obtain the Eupatorium adenophorum toxic component Euptox A removal rate of 100%, further dry, pulverize, pass through 60 mesh sieves.

[0055] S5. Fill the pulverized grain amaranth into the steam explosion device, and explode instantly after maintaining the pressure for 40 seconds under the pressure of 2.5 MPa. The grain amaranth obtained is further dried, pulverized, and passed through a 60-mesh sieve.

[0056] Product processing 800 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com