Puffed fish feed and production method thereof

A production method and fish feed technology, applied in feed, animal feed, animal feed and other directions, can solve the problems of increasing the complexity of the equipment, reducing the crushing effect, and occupying the lever, so as to reduce the crushing workload, and the puffing operation is sufficient and difficult. The effect of accidental flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

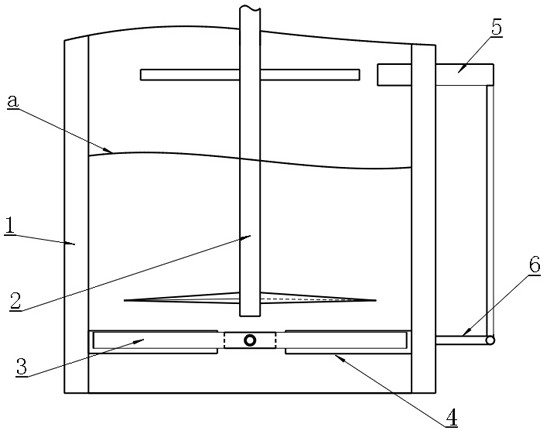

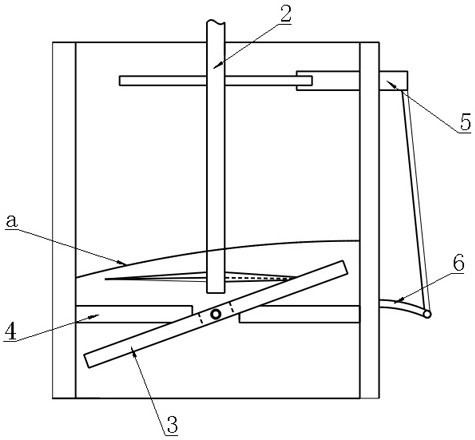

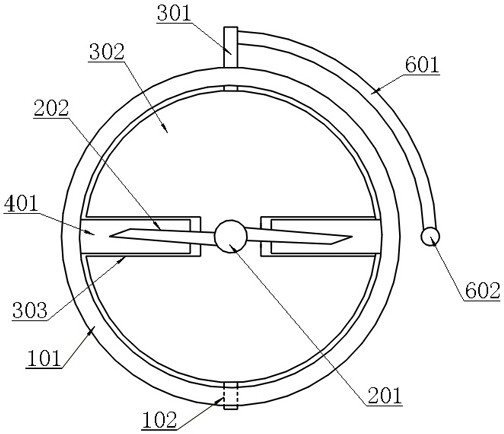

[0039] Example: as attached Figure 1-6 As shown, a kind of extruded fish feed includes soybean meal powder, peanut meal powder and cottonseed meal powder, the particle diameter of the soybean meal powder is 0.1-0.5mm, and the particle diameter of the peanut meal powder is 0.2-0.7mm. The particle size of cottonseed meal powder is 0.05-0.3mm.

[0040] In this example, the combination of soybean meal, peanut meal, and cottonseed meal ensures that various nutrients such as oil, protein, sugar, vitamins, and mineral elements are rich in types and sufficient in content, and according to the different types of the three types of meal Difficulty of puffing, the three different particle size ranges mentioned above are determined to ensure that the subsequent puffing operation is thorough and the crushing workload is as small as possible.

[0041] The soybean meal powder, peanut meal powder and cottonseed meal powder are respectively obtained by a rotary feeding type pulverizer, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com