Quantitative collection device for extracting starch by breaking skin of waxy corn

A quantitative collection, waxy corn technology, applied in the preparation of test samples, grain processing and other directions, can solve the problems of single structure, poor practicability, low accuracy of detection data, etc., to improve feeding speed, improve grinding ability, and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

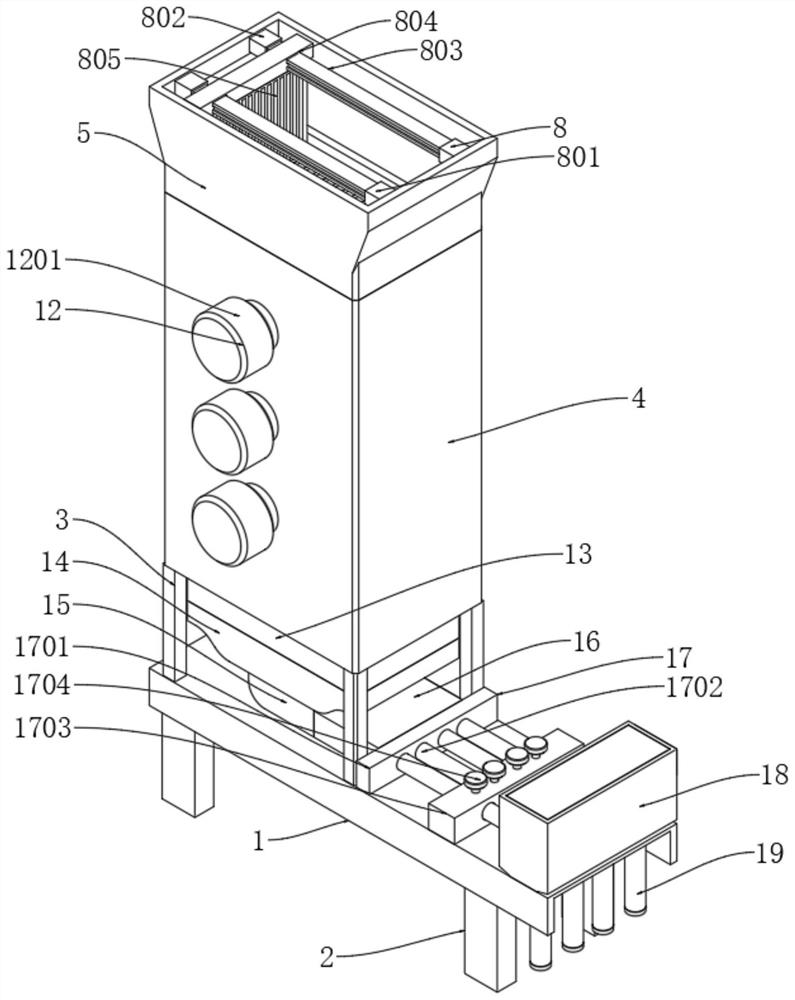

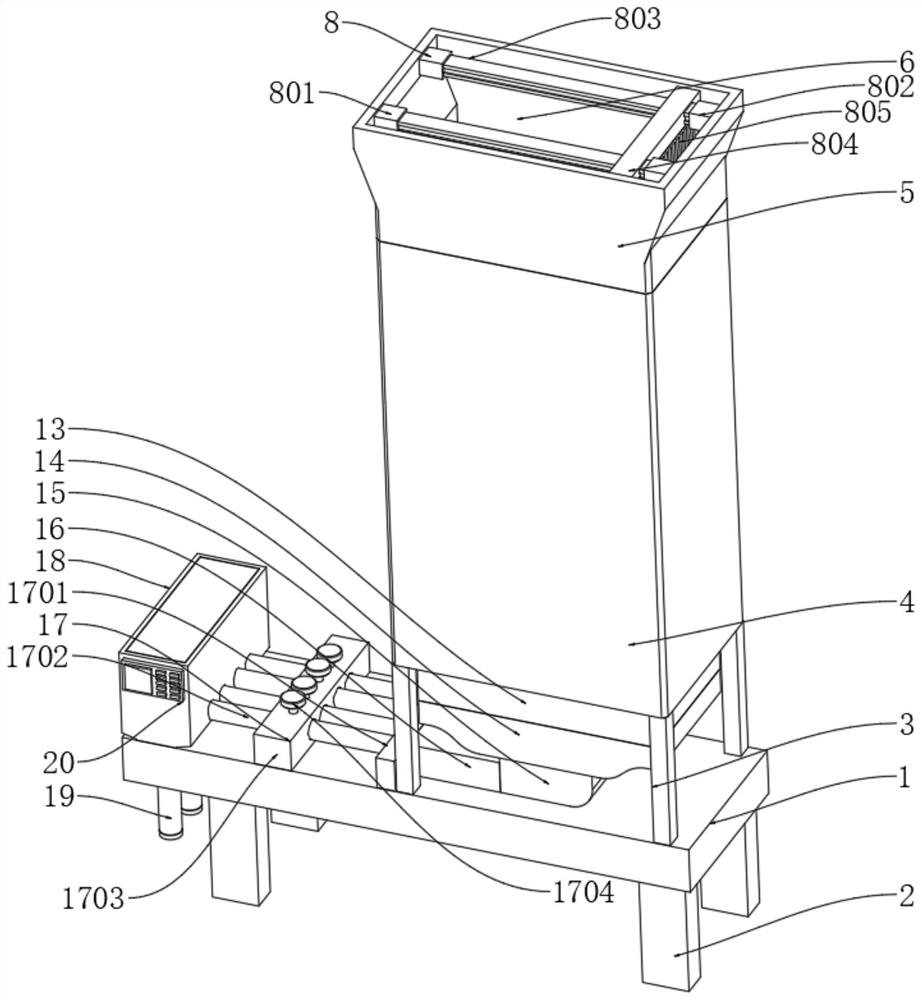

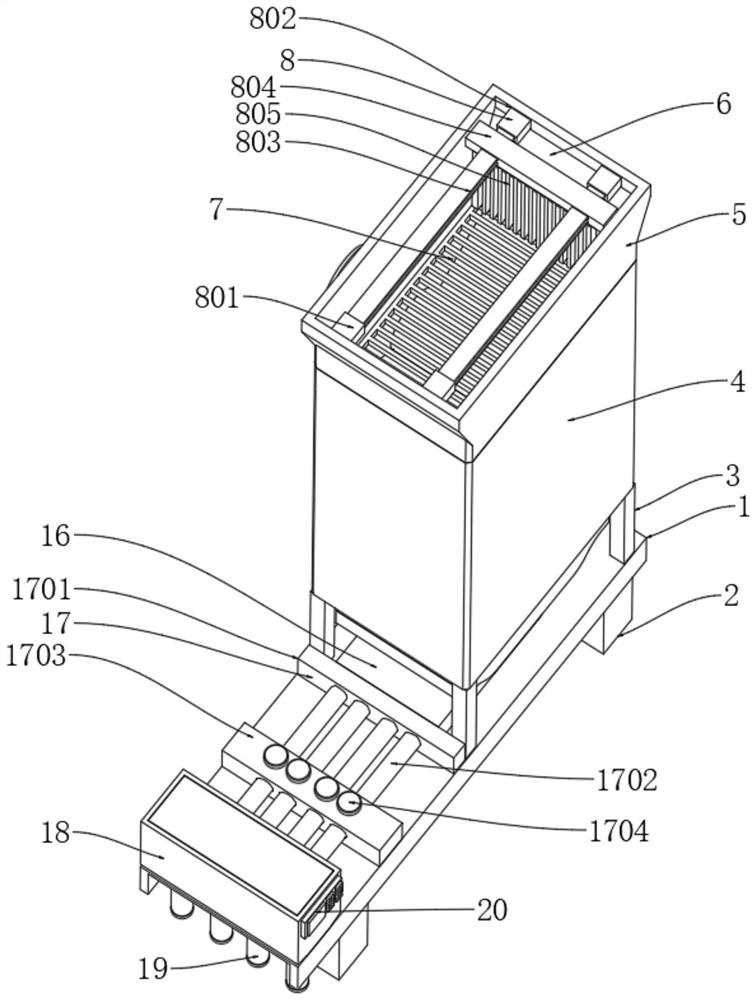

[0033] Example 1: See Figure 1-8 , a quantitative collection device for extracting starch from waxy corn, comprising a base plate 1, a bottom support column 2 is fixedly installed on the bottom of the base plate 1, a top support column 3 is fixedly installed on the top of the base plate 1, and a top support column 3 is fixed on the top of the top support column 3 A broken skin crushing box 4 is fixedly installed, and a feed box 5 is fixedly installed on the top of the broken skin crushing box 4. A feeding tank 6 is provided on the top of the feeding tank 5, and a feeding port is provided at the bottom end of the feeding tank 6. 7. A feeding mechanism 8 is provided inside the feeding tank 6;

[0034] The inside of the broken skin crushing box 4 is successively installed with inner broken leather case one 9, inner broken leather case two 10 and inner broken leather case three 11 from top to bottom, and inner broken leather case one 9, inner broken leather case two 10 and inner ...

Embodiment 2

[0040] Embodiment 2: the skin breaking assembly 12 includes a driving motor 1201, a bearing block 1202, a rotating shaft 1203, a skin breaking roller 1204 and a skin breaking groove 1205, the driving motor 1201 is fixedly installed on the back side of the skin breaking box 4, and the bearing block 1202 is fixedly installed On the front and back sides of the inner broken leather case one 9, the inner broken leather case two 10 and the inner broken leather case three 11, the rotating shaft 1203 is rotatably connected to the inside of the bearing seat 1202, and the outer side of the rotating shaft 1203 is fixedly equipped with a broken skin roller 1204, The bottom of broken leather case one 9, inner broken leather case two 10 and inner broken leather case three 11 is provided with a broken leather groove 1205;

[0041] Inner broken suitcase 1 9, inner broken suitcase 2 10 and inner broken suitcase 3 11 have the same specifications, inner broken suitcase 1 9, inner broken suitcase ...

Embodiment 3

[0043] Embodiment 3: The conveying assembly 17 includes installation seat 3 1701, communication pipe 1 1702, installation seat 4 1703 and control valve 1704, installation seat 3 1701 is fixedly installed on the top of the bottom plate 1, communication pipe 1 1702 is fixedly installed on the installation seat On the outside of the third 1701, the outer side of the communication pipe one 1702 is fixedly installed with the installation seat four 1703, and the top of the installation seat four 1703 is provided with a control valve 1704;

[0044] Intercommunication pipe one 1702 and control valve 1704 are provided with the same four groups, intercommunication pipe one 1702 is located between material delivery pipe two 16 and storage box 18, intercommunication pipe one 1702, material delivery pipe two 16 and storage box 18 are connected to each other Pass;

[0045] Specifically, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com