Tunnel support for drilling and blasting and TBM combined construction and support construction method thereof

A combination and tunnel technology, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve the problems of easy landslides, poor support effect, landslides at the entrance of the tunnel, etc., and achieve the effect of avoiding the collapse of the tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

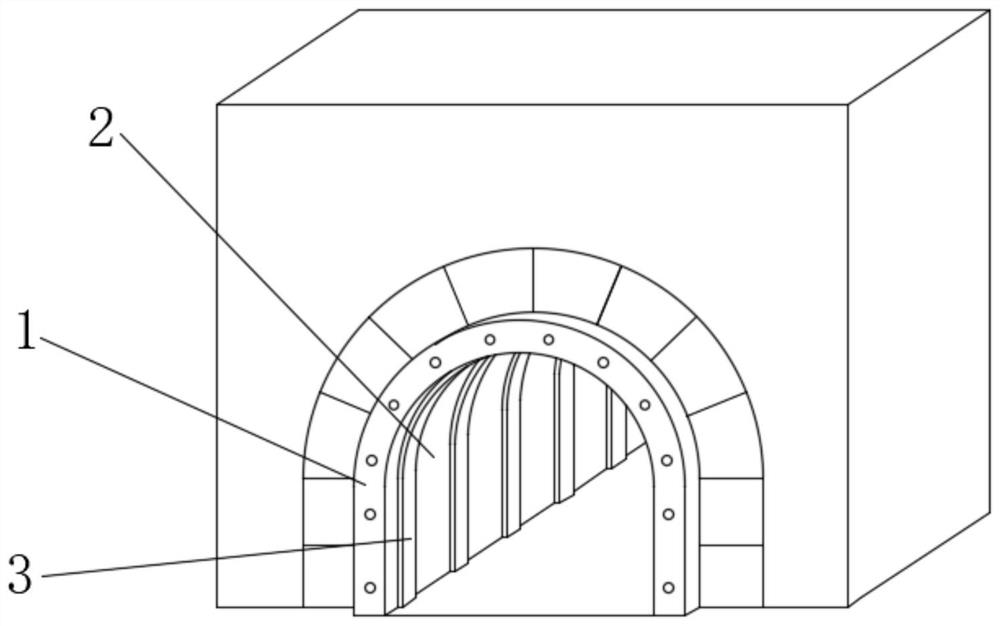

[0035] Such as Figure 1 to Figure 8 Shown: A tunnel support for drilling and blasting + TBM combined construction, including

[0036] The opening supporting assembly 1 is arranged on the outside of the opening of the drilled tunnel for supporting the opening, and it consists of a pre-buried pipe 5 inserted in the opening hole 4 at the opening, through wire binding and the pre-embedded pipe 5. The buried pipe 5 is fixedly connected to the hole pre-embedded steel bar 8, and the reinforcement steel plate 6 attached to the outer wall of the hole and located outside the embedded pipe 5;

[0037] The hole wall support assembly 2 is arranged inside the drilled tunnel for supporting the hole wall, and it is composed of the pre-buried pipe 5 inserted in the hole wall drill hole 10 provided by the hole wall, and the wire and the described The pre-embedded steel bars 11 fixedly connected to the embedded pipe 5, and the precast concrete slabs 12 that pass through the embedded pipe 5 and...

Embodiment 2

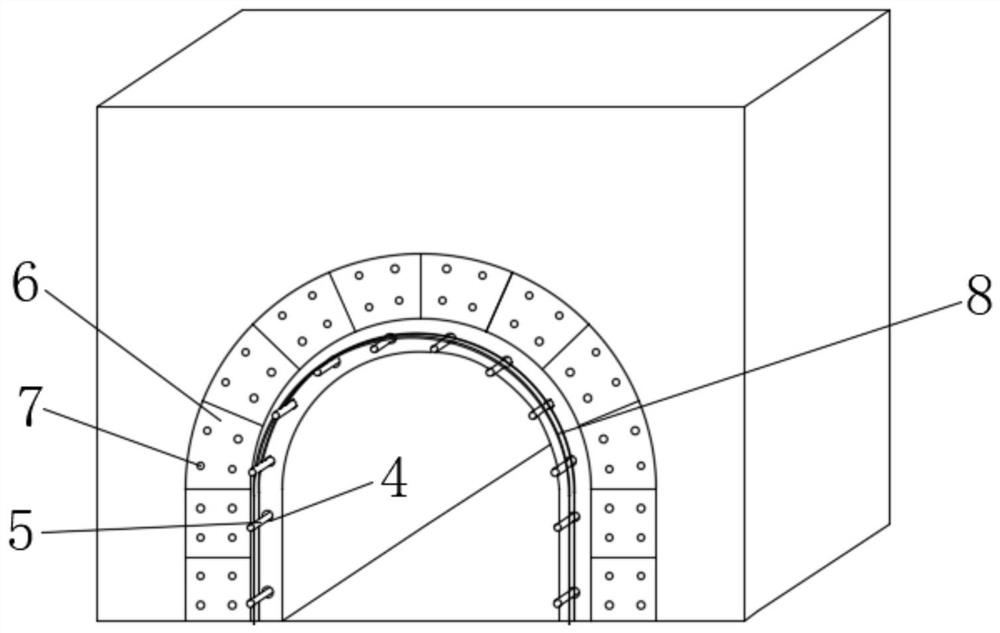

[0043] Such as Figure 1 to Figure 8 As shown, a tunnel support for drilling and blasting + TBM combined construction, including

[0044] The opening supporting assembly 1 is arranged on the outside of the opening of the drilled tunnel for supporting the opening, and it consists of a pre-buried pipe 5 inserted in the opening hole 4 at the opening, through wire binding and the pre-embedded pipe 5. The buried pipe 5 is fixedly connected to the hole pre-embedded steel bar 8, and the reinforcement steel plate 6 attached to the outer wall of the hole and located outside the embedded pipe 5;

[0045] The hole wall support assembly 2 is arranged inside the drilled tunnel for supporting the hole wall, and it is composed of the pre-buried pipe 5 inserted in the hole wall drill hole 10 provided by the hole wall, and the wire and the described The pre-embedded steel bars 11 fixedly connected to the embedded pipe 5, and the precast concrete slabs 12 that pass through the embedded pipe 5 ...

Embodiment 3

[0050] A tunnel support for drilling and blasting+TBM combined construction, the support method includes the following steps:

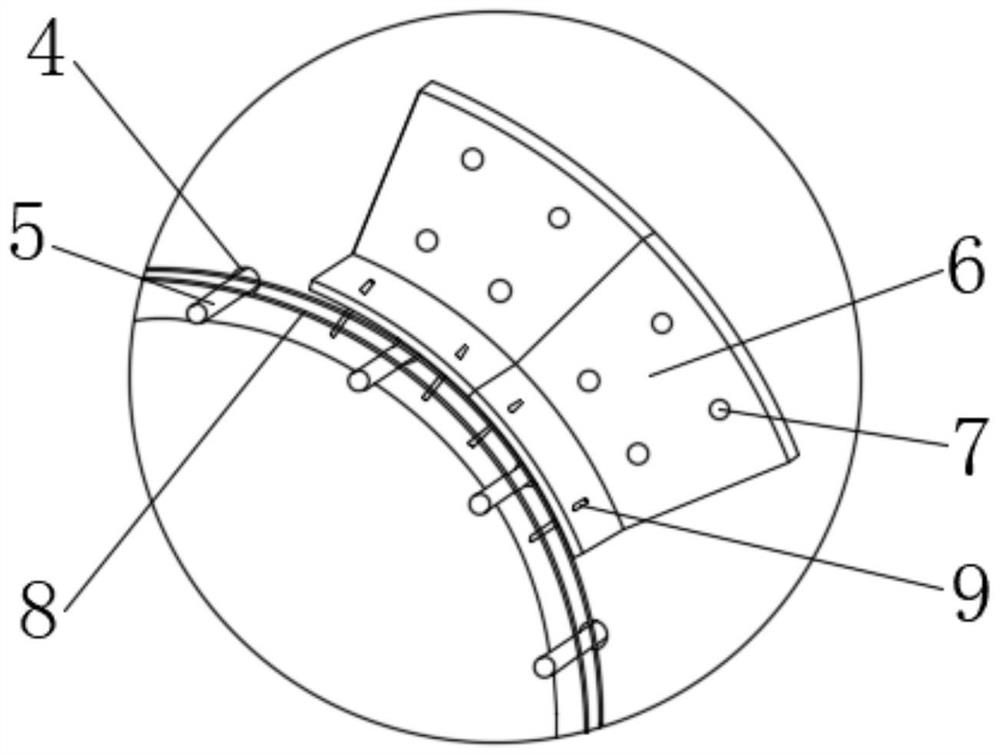

[0051] Step 1. Plan the size of the tunnel according to the construction drawing, and evenly open several hole holes 4 in an arc shape on the outside of the hole, and install pre-buried pipes 5 in the holes, and then fill the holes by grouting into the pipes. Make the pre-embedded pipe 5 firmly inserted in the drill hole, and then bind two arc-shaped pre-embedded steel bars 8 at the entrance of the hole, and connect several pre-embedded pipes 5 at the entrance to form an arc-shaped reinforcement cage like structure,

[0052] Step 2: One side of the reinforced steel plate 6 is fixedly connected to the outer side wall of the hole through the fixing pin 7, the other side of the reinforced steel plate 6 passes through the pre-embedded rod 9, and the pre-embedded rod 9 passes through one end of the reinforced steel plate 6 and The pre-embedded steel bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com