Self-calibration method and device for spatial attitude of optical displacement measuring head

A space attitude and self-calibration technology, applied in the direction of optical devices, measuring devices, surveying and navigation, etc., can solve problems such as difficulty in adapting to high-efficiency and normalized calibration, high cost, and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

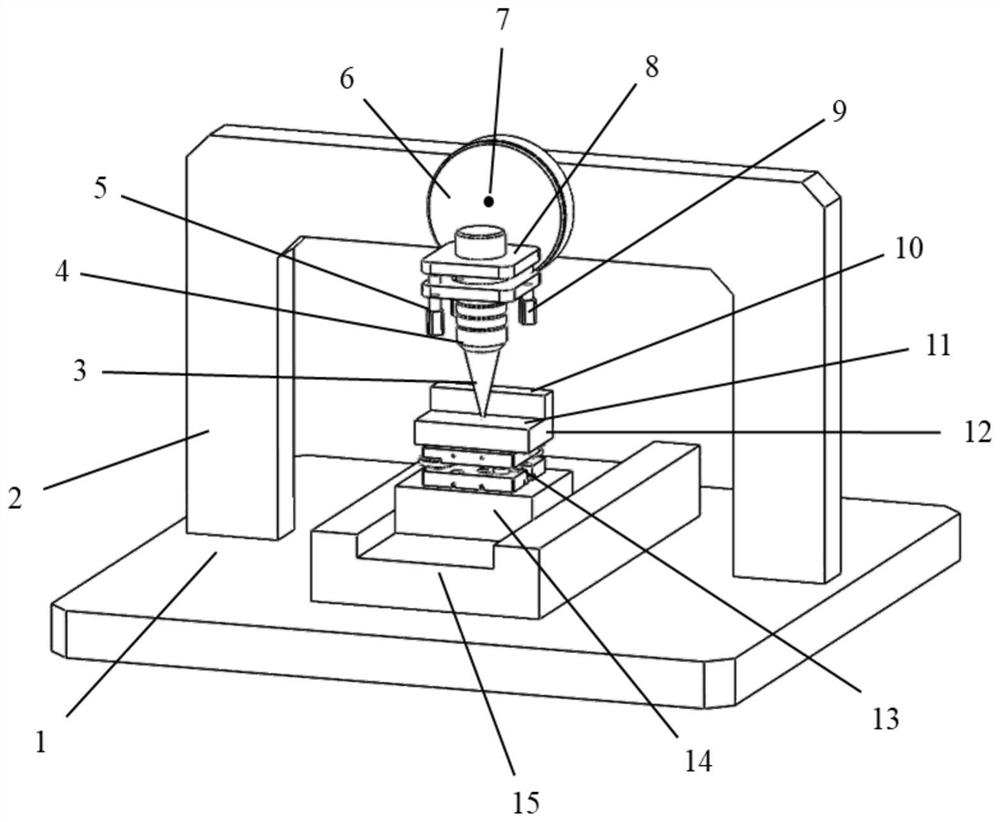

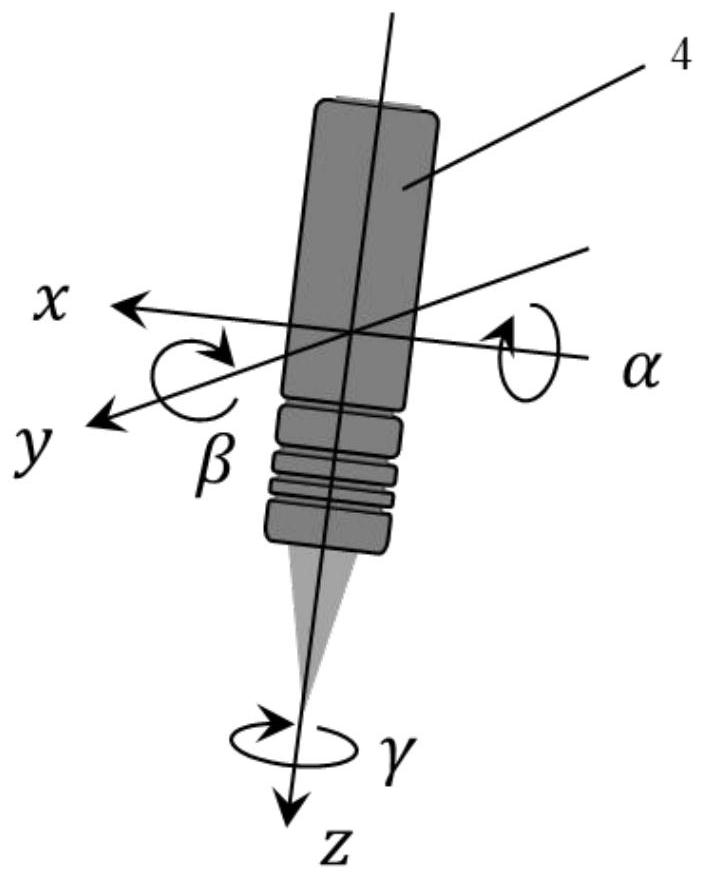

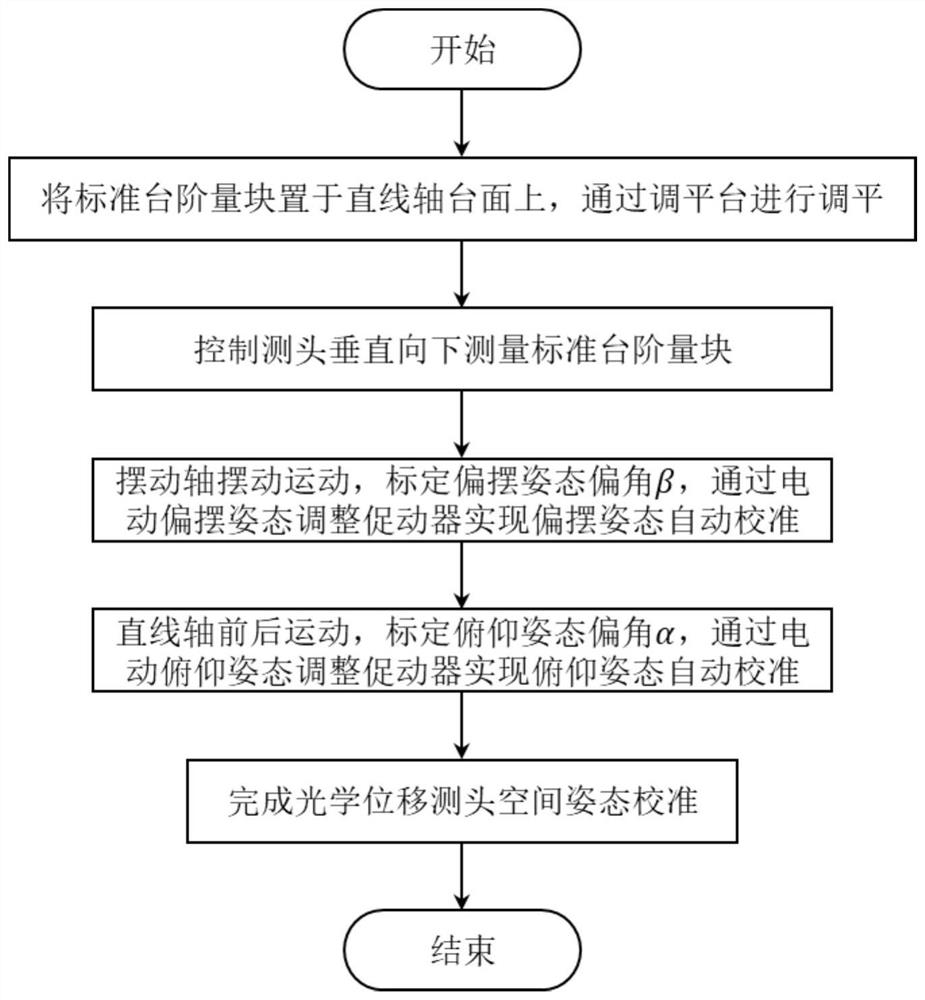

[0047] like figure 1 As shown, the gantry (2) is installed on the base (1), the center of the gantry (2) fixes the oscillating table (6), and rotates around the rotation center (7), and the electric adjustment frame (8) is installed on the oscillating table (6). ), the electric adjustment frame is driven by the electric pitch attitude adjustment actuator (5) and the electric yaw attitude adjustment actuator (9) to adjust the attitude of the optical displacement measuring head (4). A linear motion axis stator (15) and a linear motion axis mover (14) are installed at the center of the base (1). The workpiece adjustment platform (13) and the standard step gauge block (12) are installed successively on the top. The optical displacement measuring head (4) emits a measuring beam (3), which can obtain the position measurement of the high surface (10) of the standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com