Verification and calibration system of high-pressure oil flowmeter and working method of verification and calibration system

A technology of calibration system and flowmeter, applied in the field of verification and calibration of high-pressure oil flowmeter, can solve the problems of different resistance and driving force, the influence of the inability to assess the measurement accuracy, and the inability to assess the influence of the measurement accuracy of the high-pressure flowmeter to achieve accurate verification. Calibration, the effect of large direct economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

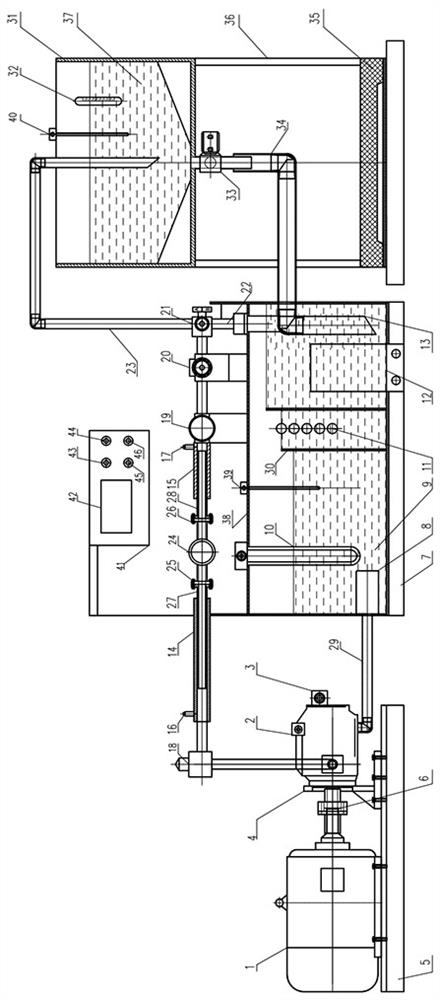

[0030] The specific embodiment of the specific solution of the present invention will be further elaborated in conjunction with the accompanying drawings.

[0031] As shown in the figure, a verification and calibration system for a high-pressure oil flowmeter includes an adjustable stepless variable high-pressure liquid supply device, a working fluid parameter guarantee system, a working fluid delivery control test flowmeter clamping system, and a working fluid weighing measurement systems and process control systems.

[0032]1. Adjustable stepless variable high pressure liquid supply device: including variable frequency motor 1, servo variable plunger pump 2, servo flow regulator 3, pump bracket 4, base 5, coupling 6 as shown in the figure. 1 is connected to the servo variable plunger pump 2 through the coupling 6, the servo flow regulator 3 is set on the servo variable plunger pump 2, and the servo variable plunger pump 2 is guaranteed with the working fluid parameters throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com