Test device for automatically and synchronously collecting and clamping attitude and orbit control engine products

A technology of automatic synchronization and test device, which is applied in the direction of engine test, machine/structural component test, measurement device, etc., can solve the problems of large measurement error, artificial physical strength, long test time, etc., to improve accuracy and stability stability, avoid time out-of-sync, reduce the effect of operation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

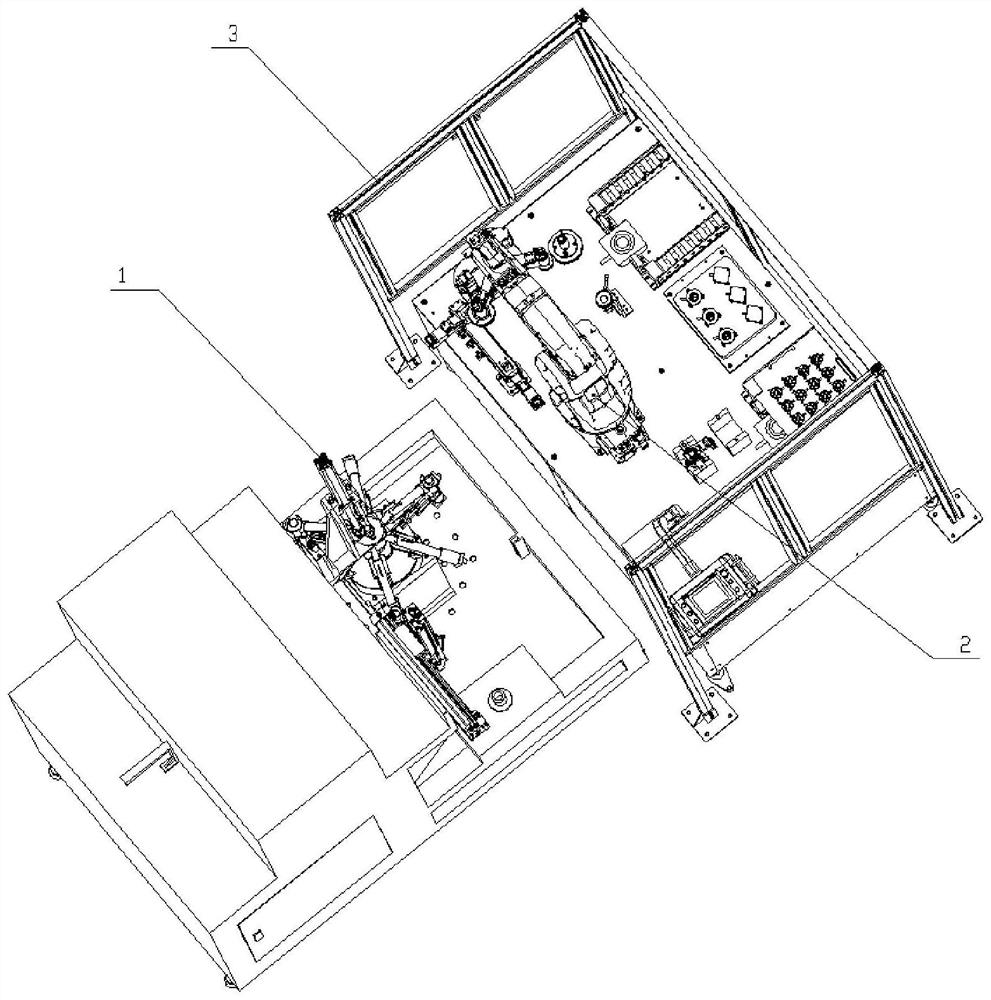

[0048] Such as figure 1 As shown, the test device for automatic synchronous collection and clamping of attitude-orbit control engine products provided by the present invention includes automatic synchronous collection device 1 and robot automation system 2; wherein:

[0049] Such as figure 2 As shown, the automatic synchronous collection device 1 includes a cabinet body, a process system, a tooling pressing mechanism, multiple sets of connecting rod devices, a rotating index plate, a lifting cylinder and a weighing mechanism; wherein:

[0050] The cabinet body 101 is used to provide installation space. The tooling pressing mechanism, rotating index plate, lifting cylinder and weighing mechanism are installed on the cabinet body 101 respectively, and the process system is installed in the cabinet body 101;

[0051] The tooling pressing mechanism 102 is installed on the lateral mounting plate 124 of the cabinet body 101 through the Z-direction manual translation mechanism 106,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com