Pipeline corrosion monitoring method and system and electronic equipment

A pipeline and preset position technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as large deviation, deviation of test results, and inability to effectively evaluate the safety status of corroded pipe sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

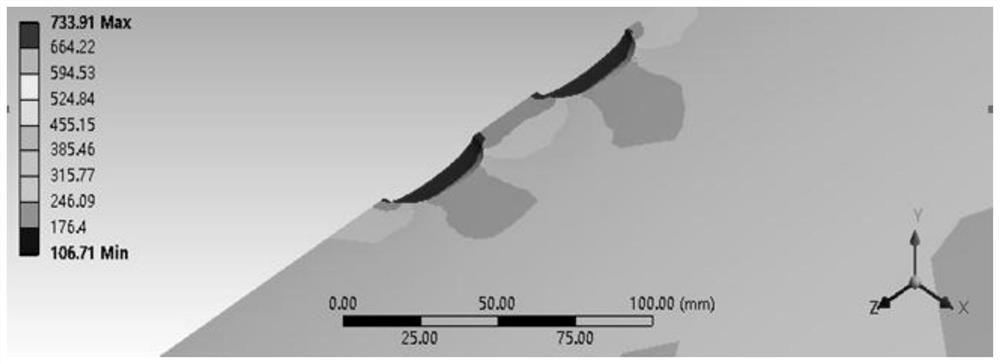

Examples

Embodiment Construction

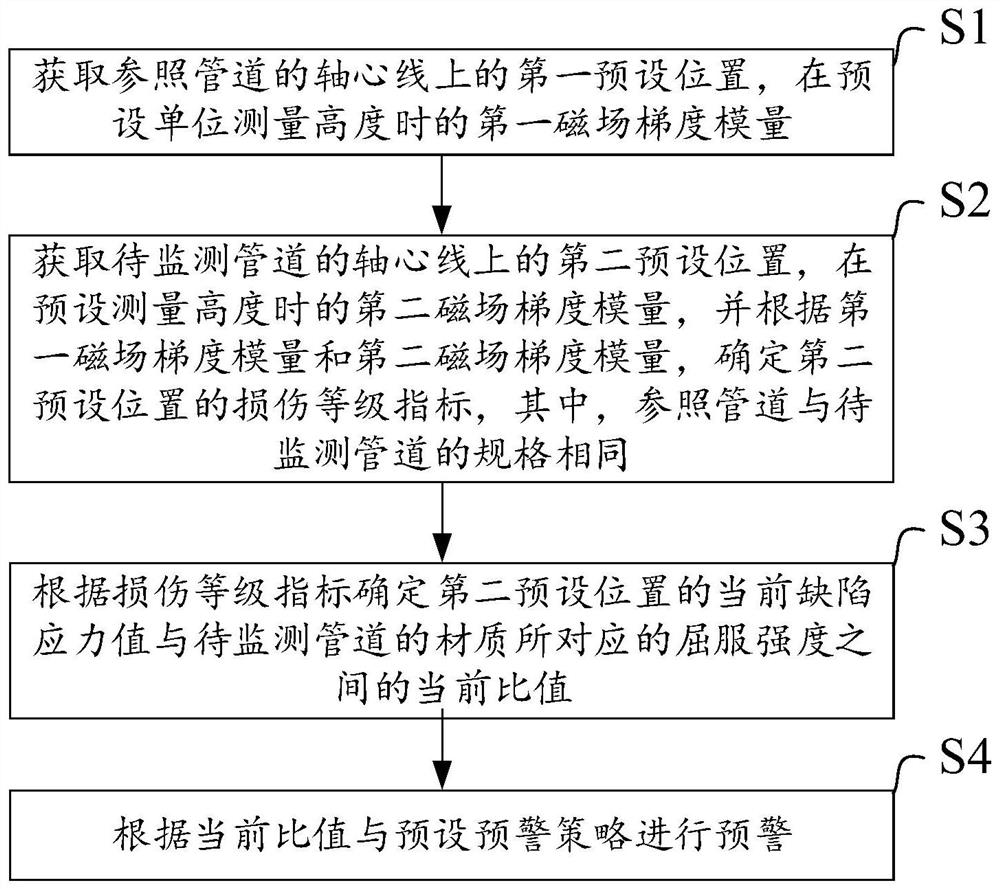

[0061] like figure 1 As shown, a method for monitoring pipeline corrosion in an embodiment of the present invention includes the following steps:

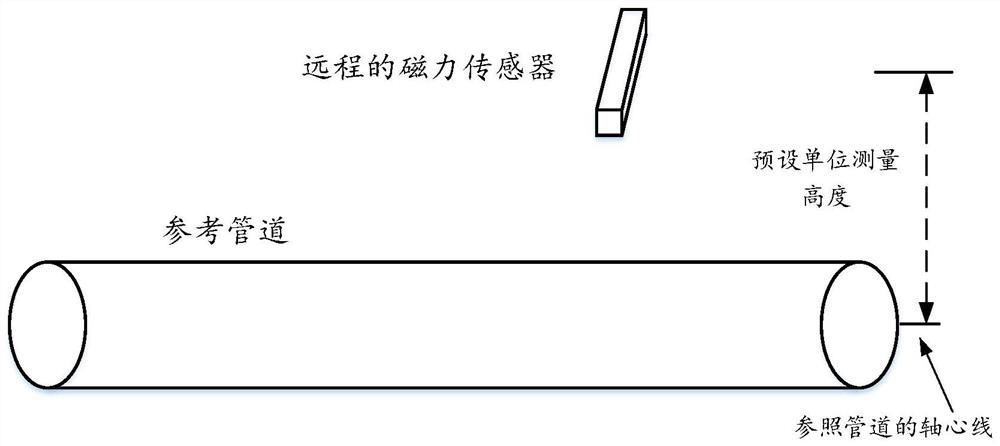

[0062] S1. Obtain the first magnetic field gradient modulus when measuring the height in preset units at the first preset position on the axis line of the reference pipeline;

[0063] Among them, the reference pipeline can be understood as a standard pipeline in compliance with industrial application standards, free from any corrosion and other damages and defects;

[0064] The first preset position can be an artificially selected position, or any position on the axis line of the reference pipeline. Since the reference pipeline is not subject to any corrosion and other damages and defects, when the first preset position is the reference At different positions on the axis line of the pipeline, the obtained first magnetic field gradient modulus at the preset unit measurement height has very little deviation and can be considered to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com