Staggered inner claw tooth type shrimp head removing method and system

A technology of claws and shrimp heads, which is applied in the field of staggered internal claws as a shrimp decapitation method and system, can solve the problems of increasing the risk of cross-contamination between humans and shrimps, easily cutting off too much shrimp meat, and being unsuitable for processing, etc., to achieve saving Labor cost, good effect, and accurate adjustment of spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

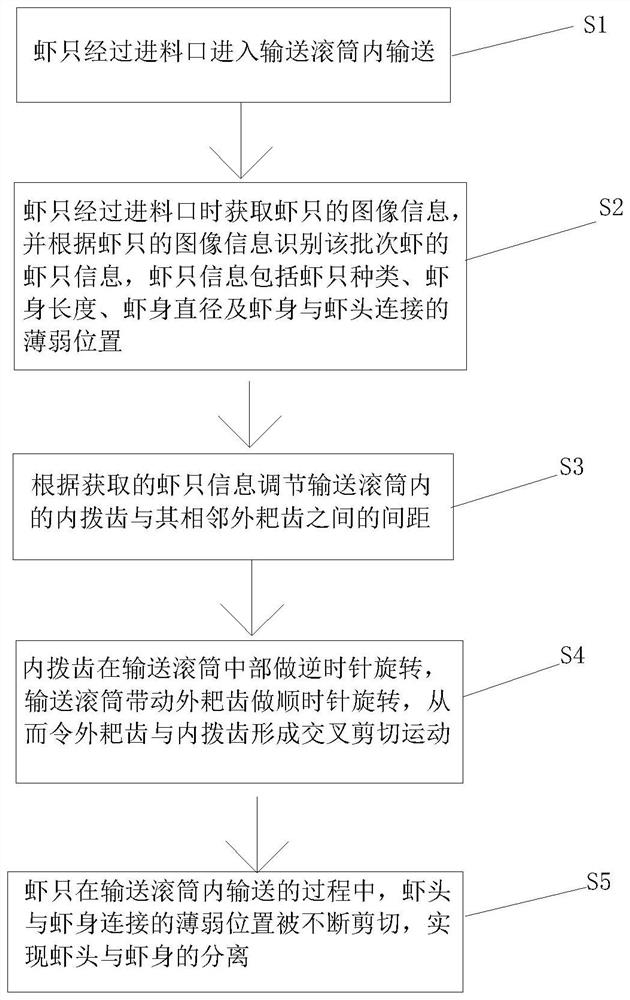

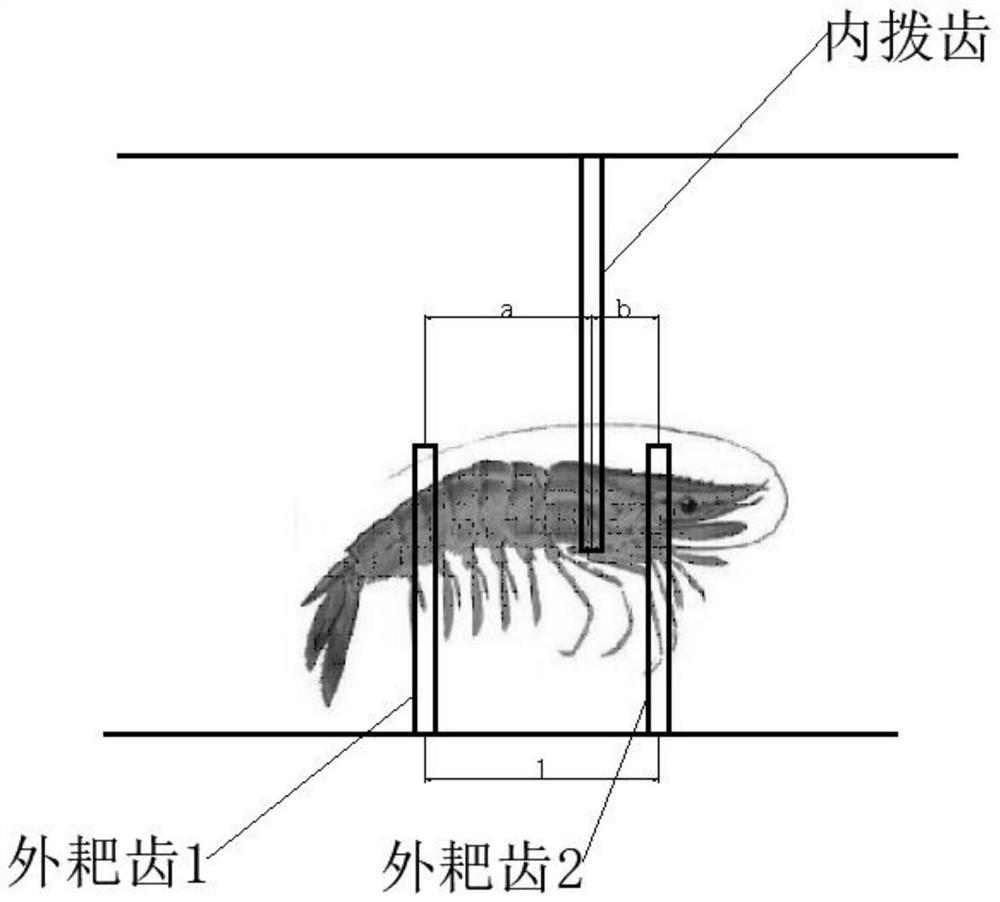

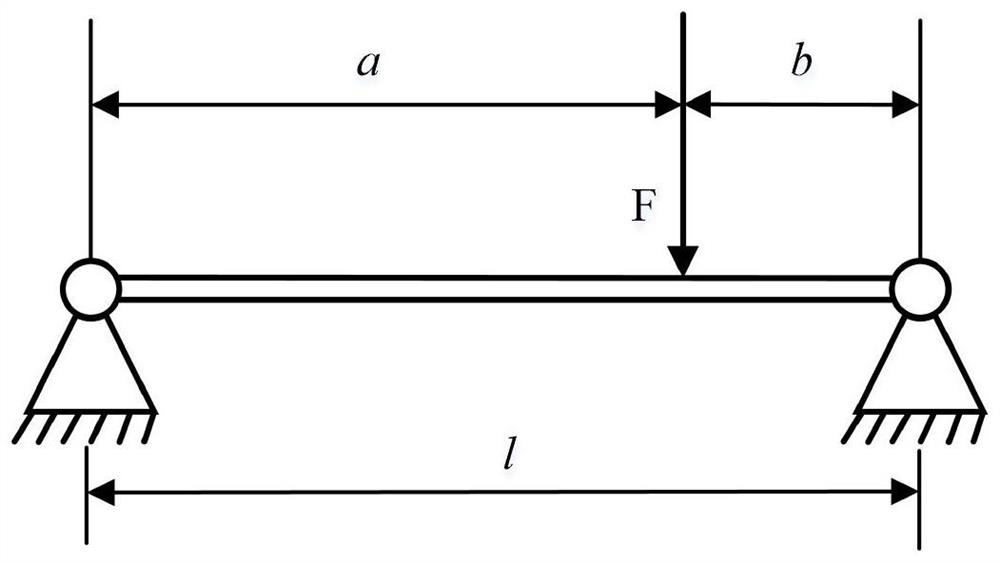

[0051] In one embodiment, the present invention discloses a method for decapitating shrimp with staggered inner claw teeth, the method includes the following steps:

[0052] S1: Shrimp only enters the conveying drum through the feeding port for conveying.

[0053]In this embodiment, a feeding funnel is provided at one end of the conveying drum, and a feeding port is provided above the feeding funnel, and the shrimp enters the conveying drum only through the feeding port of the feeding funnel, and the shrimps are transported to the conveying drum by the conveying drum the other end of the

[0054] S2: Obtain the image information of the shrimp wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com