Sliding rail type air composite suspension

A sliding rail type, air technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of poor vibration damping performance, shortened service life, reduced vibration damping performance, etc., to improve ride comfort and control. Effects of improved stability, passability, and high-speed stability, and reduced vibration displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

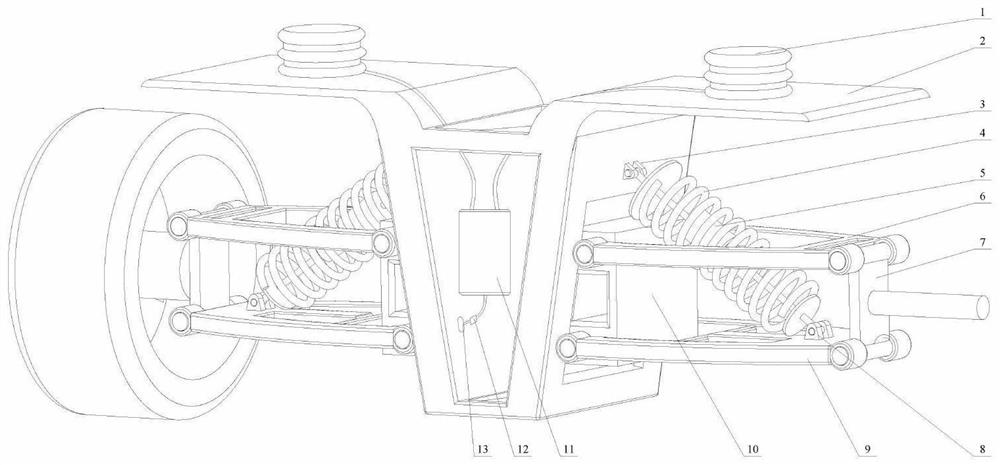

[0031] A slide rail type air composite suspension of the present invention comprises a vehicle axle 2, an upper swing arm 6, a lower swing arm 9, a damping spring 4, and a shock absorber 5, and is characterized in that:

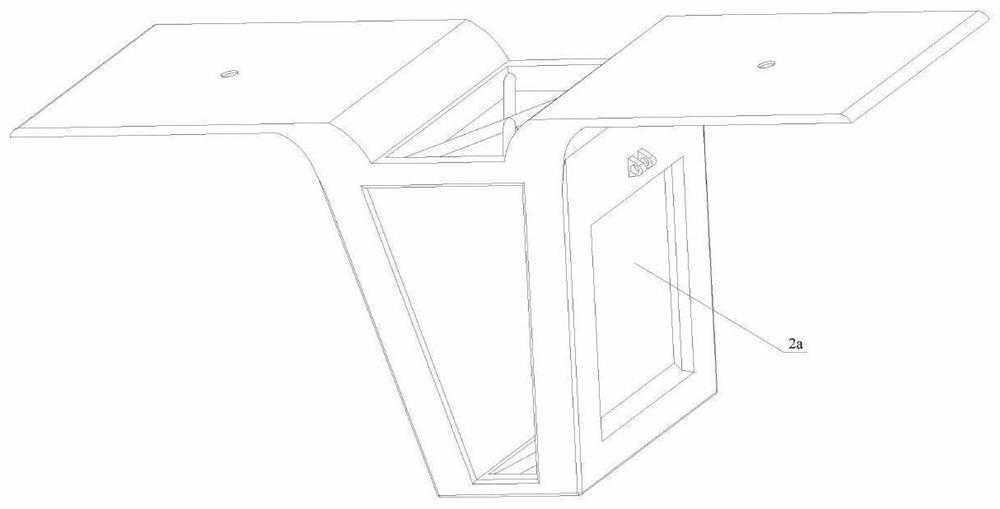

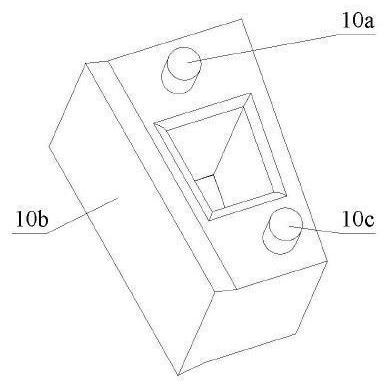

[0032] It also includes a mounting plate 7 , a swing arm support frame 10 , an air spring 1 , an air spring storage tank 11 , a displacement sensor 13 and an electric control unit 2 .

[0033] The mounting plate shaft 7e on the said automobile mounting plate 7 is axially connected with the wheel hub shaft of the tire, and is relatively stationary; Hinged, the other end 6c, 6d of the upper swing arm 6 is hinged with the upper swing arm mounting column 10a of the swing arm support frame 10; Hinged, the other end 9c, 9d of the lower swing arm 9 is hinged with the lower swing arm mounting column 10c of the swing arm support frame 10; the guide rail slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com