Two-cavity type heat conduction switch for extremely low temperature equipment and extremely low temperature equipment

An ultra-low temperature, cavity-type technology, applied in the field of two-cavity thermal conduction switches and ultra-low temperature equipment, can solve problems such as unknown reliability and achieve the effect of high thermal conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

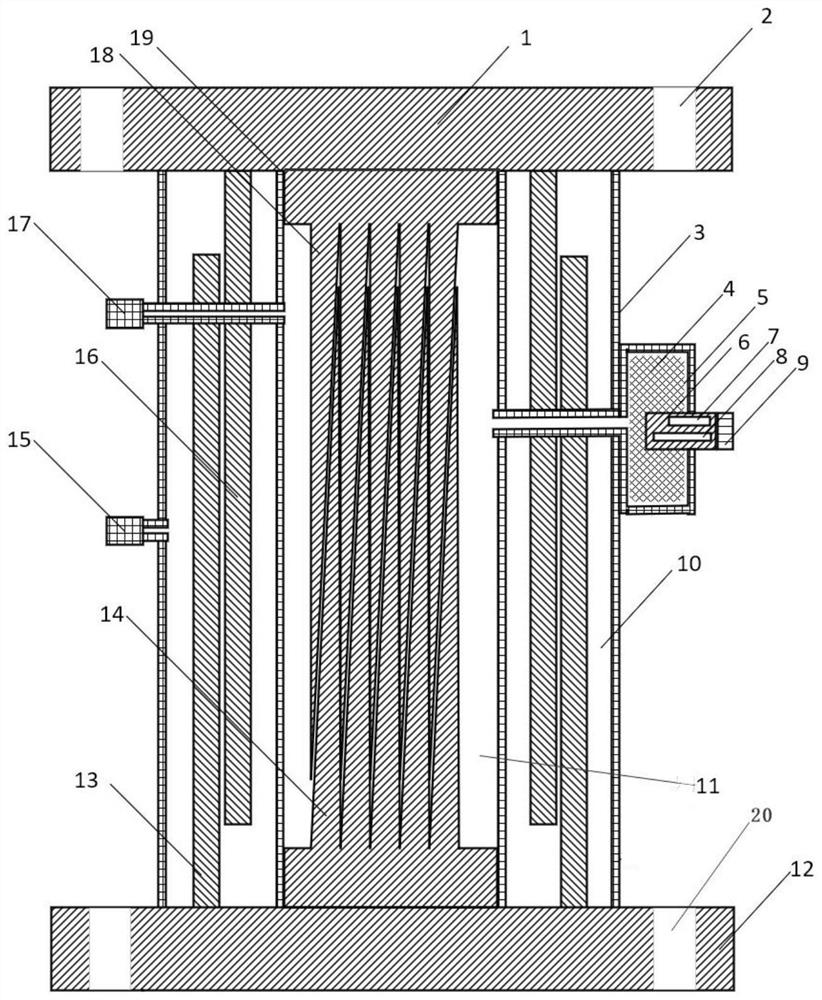

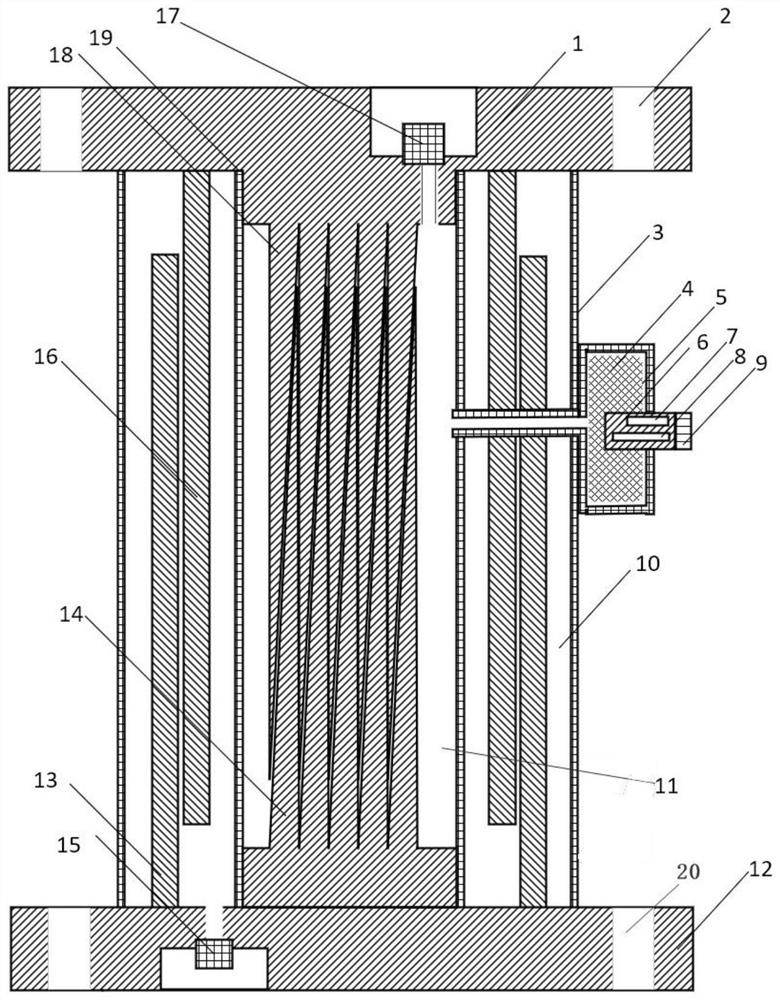

[0046] This embodiment provides a two-cavity heat conduction switch (hereinafter referred to as a thermal switch) for extremely low temperature equipment, wherein, in the field of low temperature equipment, extremely low temperature refers to equipment that can provide a temperature range below 1K, such as figure 1 As shown, it includes: an upper fixing plate 1, a lower fixing plate 12, an outer cavity wall 3 and an inner cavity wall 19;

[0047] The outer cavity wall 3 is arranged between the upper fixed plate 1 and the lower fixed plate 12, and the three form a closed cavity, that is, an external cavity 10; the external cavity 10 is provided with an external cavity heat conduction device And the two constitute an external switch;

[0048] The inner cavity wall 19 is arranged between the upper fixing plate 1 and the lower fixing plate 12, and the three form a closed cavity, that is, the inner cavity 11, and the inner cavity wall 19 is arranged on the outer cavity wall. 3. In...

Embodiment 2

[0076] This embodiment provides an extremely low temperature device, in which the two-cavity heat conduction switch for the extremely low temperature device described in any one of Embodiment 1 is set.

[0077] In summary, the present invention provides a two-cavity heat conduction switch for extremely low temperature equipment. The heat switch combines an active heat switch and a passive heat switch to achieve a two-stage cooling effect. The main feature of the thermal switch is that the thermal switch mainly has a double-layer chamber structure, and two different working media are used in the two chambers: such as helium and nitrogen, so that the thermal switch can have two switching points. In the cooling process of extremely low temperature equipment, in order to have a higher thermal conductivity in the high temperature area, the nitrogen in the outer cavity is in a gaseous state, and the thermal switch is turned on. After reaching the nitrogen liquefaction temperature, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com