Condenser heat transfer tube cavitation jet cleaning device and cleaning method thereof

A technology for cleaning devices and condensers, applied to cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve problems such as cavitation bubbles in difficult pipe sections, and achieve good cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

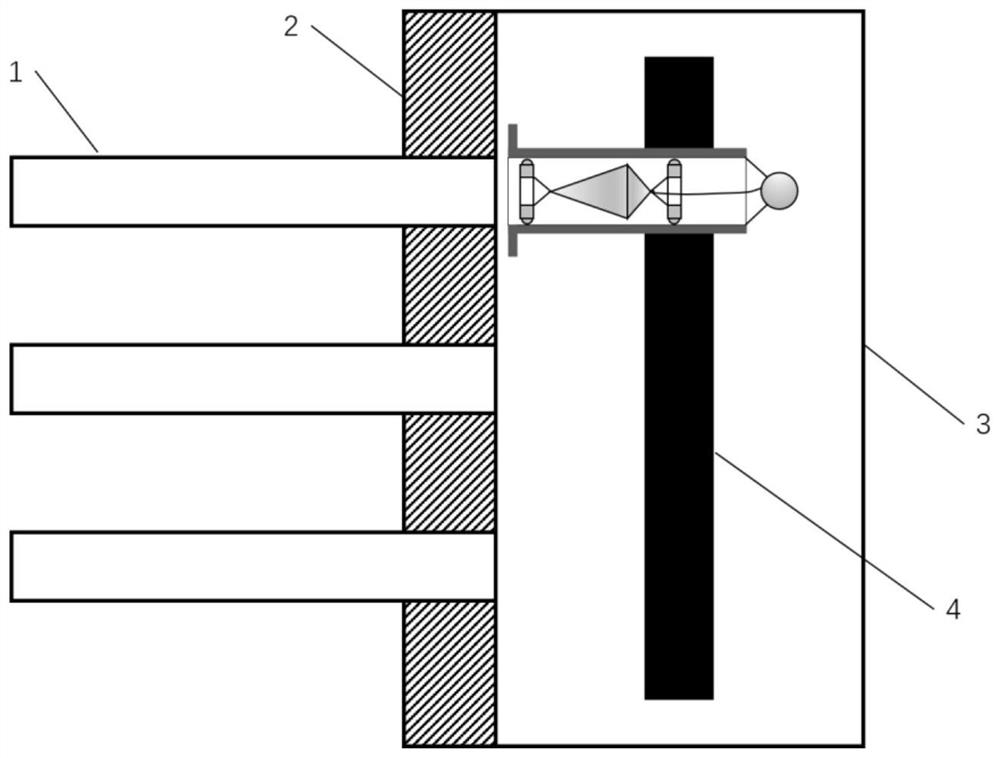

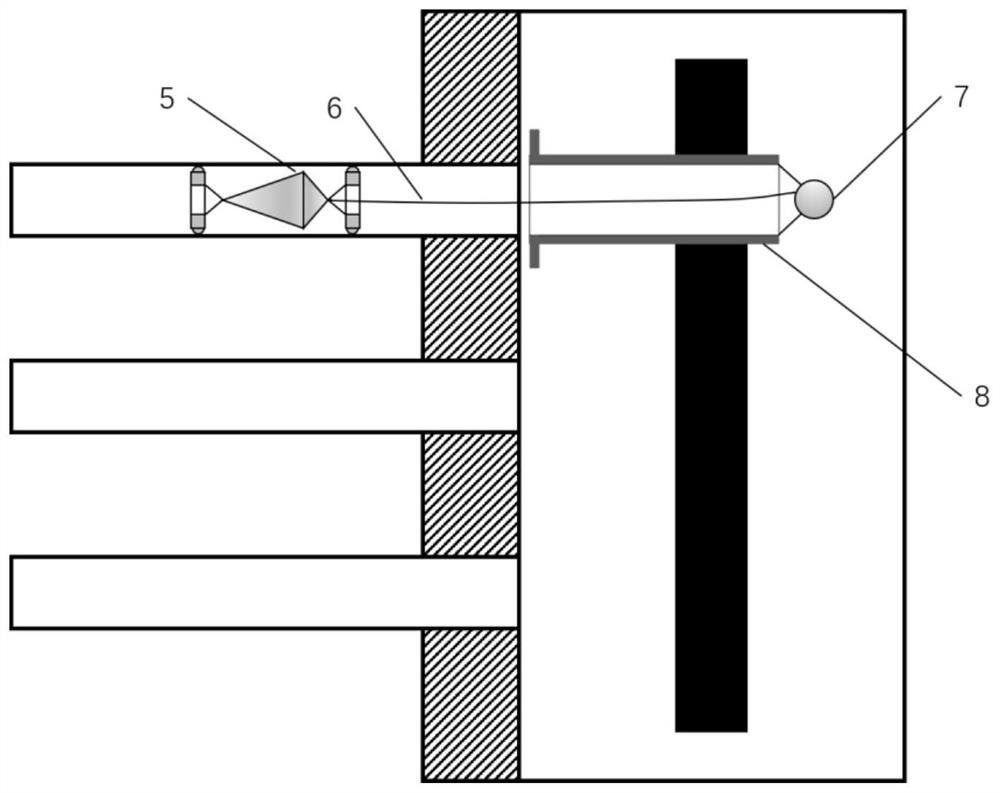

[0039] Example: see attached Figure 1-3 , the present invention provides a technical solution: a condenser heat transfer tube cavitation jet cleaning device, which includes:

[0040] Condenser inlet water chamber 3;

[0041] Condenser tube plate 2, condensate tube plate 2 is fixedly arranged on the left side wall of condenser water inlet water chamber 3;

[0042] Condenser heat transfer tube 1, multiple condenser heat transfer tubes 1 are provided, and each condenser heat transfer tube 1 is connected to the condenser water inlet water chamber 3 through the condenser tube plate 2;

[0043] The positioning mechanism 4, the positioning mechanism 4 is fixedly arranged in the water inlet chamber 3 of the condenser, the positioning mechanism 4 includes a sliding seat and a sliding block controlled by a two-dimensional robot positioning system, and a sliding block is installed on the sliding seat;

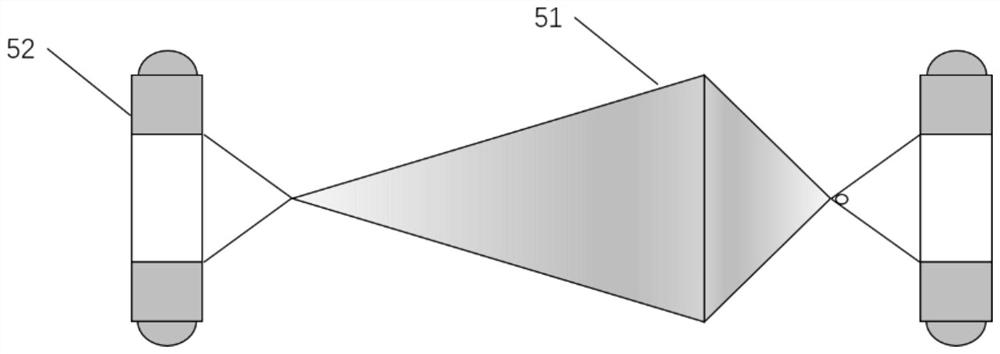

[0044] And a cleaning mechanism, the cleaning mechanism is fixedly installed on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com