Implementation method of semiconductor blue laser module with adjustable pulse width

A realization method and laser technology, applied in the direction of semiconductor lasers, semiconductor laser devices, lasers, etc., can solve the problems of inability to switch pulse width freely, low peak power, small volume, etc., and achieve flexible and adjustable power, high cost performance, and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

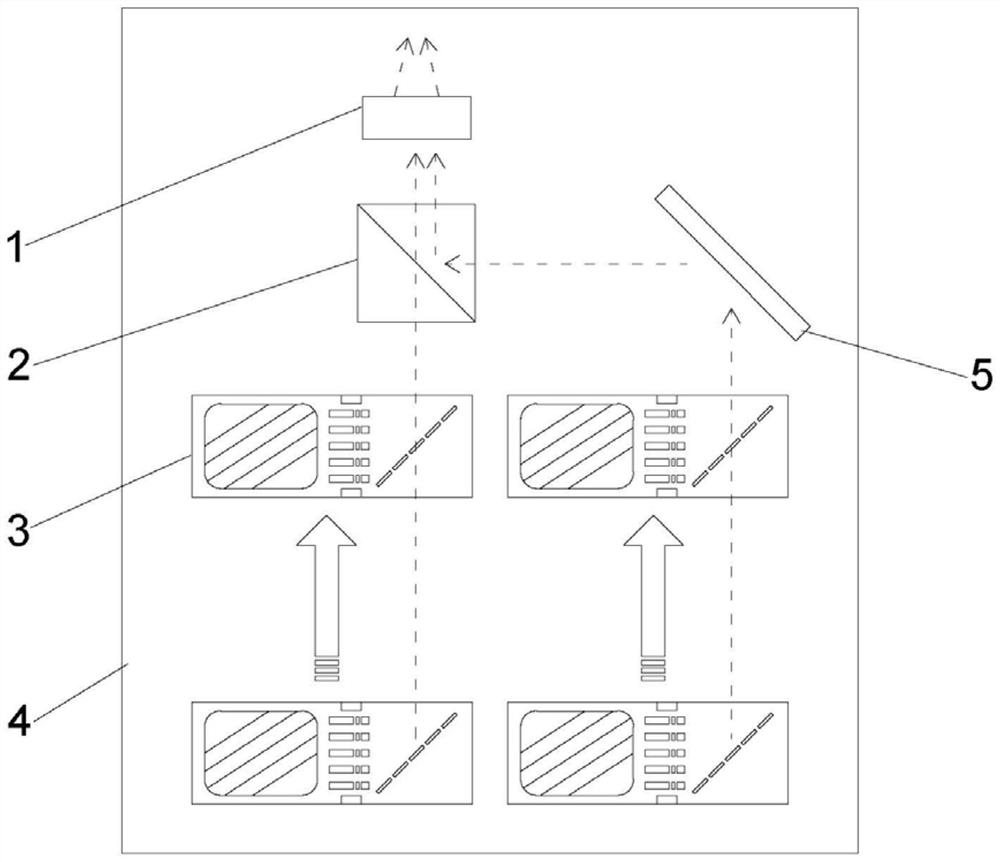

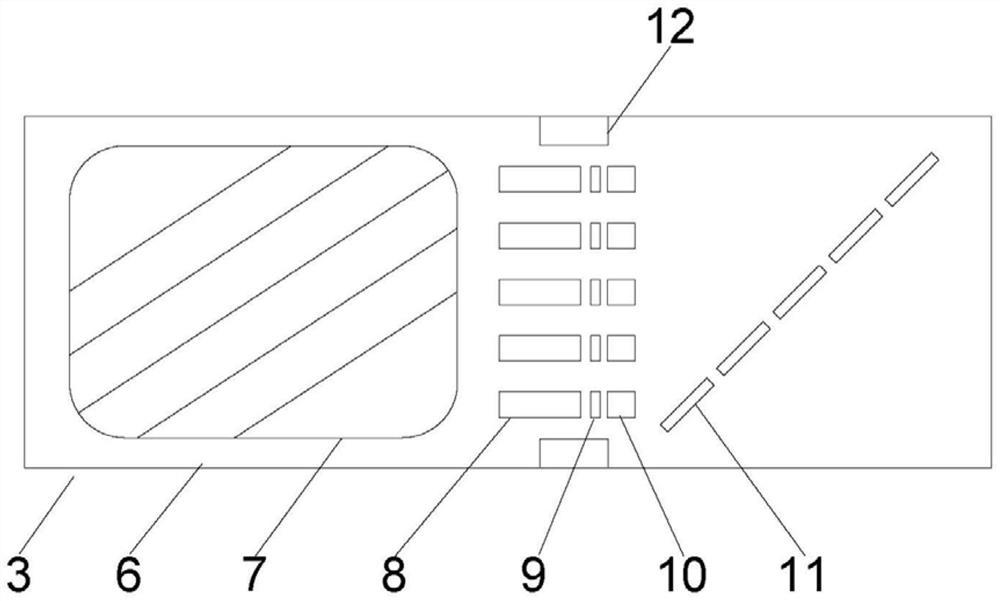

[0029] Such as figure 1 and figure 2 In the described embodiment, a method for realizing an adjustable pulse width semiconductor blue light laser module includes the packaging of the sub-module 3 and the overall assembly of the laser module, and the packaging of the sub-module 3 includes the following steps:

[0030] Step 1, packaging several COS blue light semiconductor laser chips 8 at equal intervals on the heat sink carrier 6;

[0031] Step 2, install the drive circuit control board 7 and the high-speed photodetector PD chip 12 on the heat sink carrier 6, and realize the positive and negative connections between the drive circuit control board 7 and the COS blue light semiconductor laser chip 8 respectively through gold wire bonding. Pole and the positive and negative poles of the high-speed photodetector PD chip 12 are electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com