High-strength composite bottom enamel non-stick pan

A non-stick pan and composite bottom technology, which is applied to special materials for cooking utensils, cooker brackets, kitchen utensils, etc., can solve problems such as deviation, inclination, low heat conversion efficiency, and increased pot bottom contact strength and area. , to achieve the effect of reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

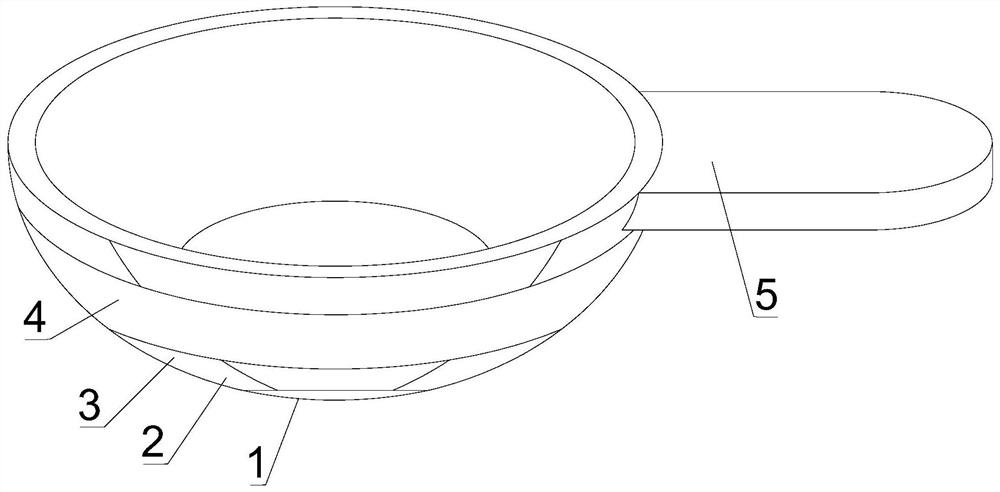

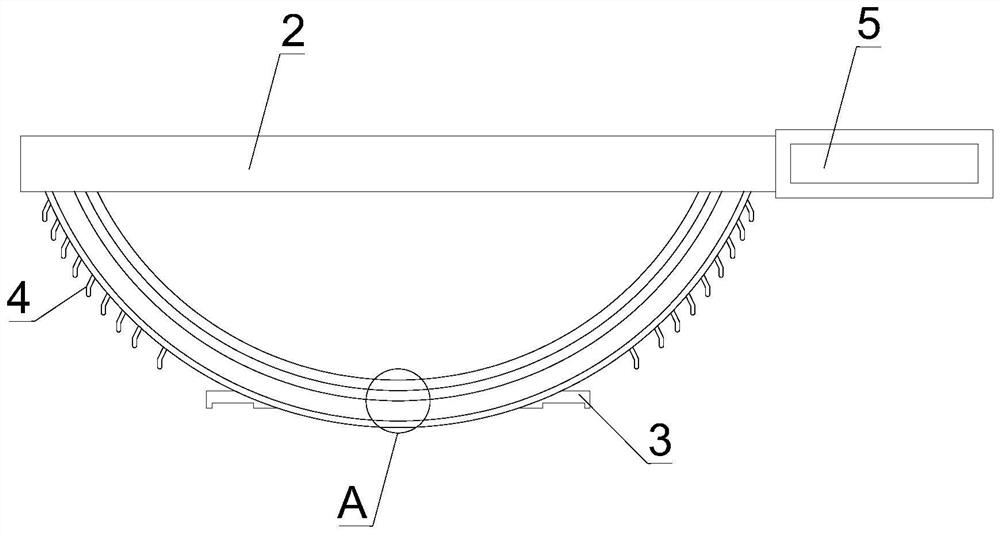

[0038] like Figure 1-8 As shown, the present invention provides a high-strength composite bottom enamel non-stick pan, comprising a composite enamel non-stick pan body 1, the composite enamel non-stick pan body 1 includes a composite pan bottom 2, and the bottom outer surface of the composite pan bottom 2 is arranged There is a gas stove support lap joint 3, a side waste heat recovery layer 4 is arranged on the outer surface around the bottom of the composite pan bottom 2, and a non-stick pan handle 5 is detachably installed on the upper right outer surface of the composite pan bottom 2 .

[0039] In this embodiment, the composite pan bottom 2 can be picked up by the non-stick pan handle 5, which can provide certain stability when the composite pan bottom 2 is placed on the stove with the gas stove support lap adapter 3, and the side The waste heat recovery layer 4 recovers and reuses the heat on the outer surface around the bottom of the composite pot bottom 2 .

[0040] l...

Embodiment 2

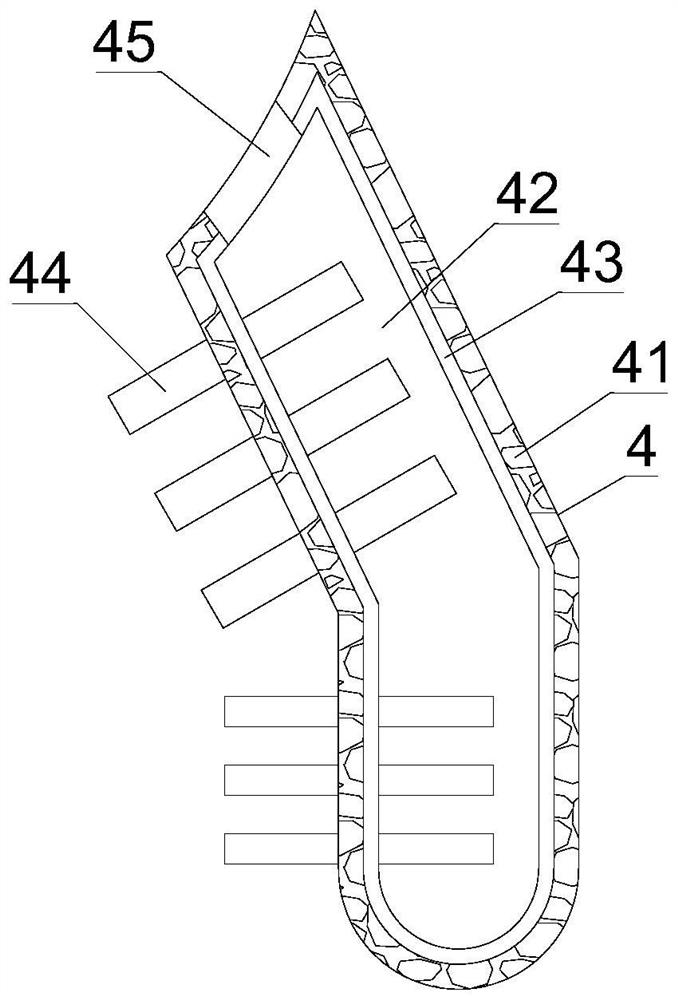

[0043] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the side waste heat recovery layer 4 includes an L-shaped guide block 41, and an L-shaped cavity 42 is arranged inside the L-shaped guide block 41 , the inner outer surface of the L-shaped cavity 42 is detachably connected with an insulating layer 43, and the left outer surface of the L-shaped flow guide block 41 is detachably connected with a heat-absorbing strip 44, and one end of the heat-absorbing strip 44 passes through The outer surfaces of the L-shaped flow guide block 41 and the insulation layer 43 extend to the inside of the L-shaped cavity 42 , and a heat transfer port 45 is arranged on the top of the L-shaped flow guide block 41 .

[0044] In this embodiment, the radians on both sides of the composite pot bottom 2 provide flow radians for the fire source and heat flow, and then block the flowing fire source and heat flow through the L-shap...

Embodiment 3

[0046] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, strip-shaped hollow grooves 31 are arranged on the outer surfaces of the front and rear sides of the gas stove bracket overlapper 3, and the strip-shaped hollow grooves 31 The inner surface of both sides is detachably connected with a side lap buffer wire 32, and the inner surface of the bar-shaped cavity 31 is slidably overlapped with a moving wheel 33, and one end of the central rotating shaft of the moving wheel 33 is movably connected with a limit bar 35. , one end of the central rotating shaft of moving wheel 33 is movably connected with connecting bracket bar 34, and a limit bar 35 is arranged on one end of connecting bracket bar 34, and the inside of limit bar 35 is provided with triangular cavity 36, and the limit bar 35 An overlapping stepped groove 37 is provided on the outer surface of the bottom, and an overlapping heat-resistant layer 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com