Automatic forming equipment for spring hook

A technology of automatic forming and spring hooks, which is applied in the direction of hook fasteners, clothing, fasteners, etc., can solve the problems of time-consuming and labor-intensive, difficult to process in large quantities, and achieve the effect of improving enterprise productivity and saving manpower for handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention is further described below in combination with the accompanying drawings.

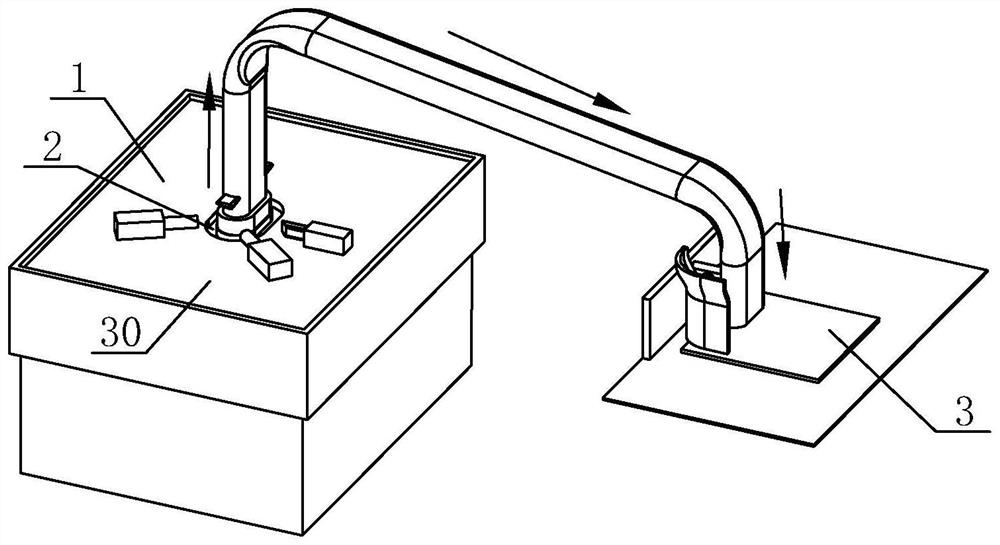

[0033] as Figure 1 The automatic forming equipment of the spring hook shown in the figure includes a bending device 1 for bending the wire X1 and a stamping cutting device 3 for stamping and cutting. The wire X1 is a bending semi-finished product after being processed by the bending device 1, the bending semi-finished product X2 is a spring hook semi-finished product after being processed by the stamping cutting device 3, and a conveying device 2 is arranged between the bending device 1 and the stamping cutting device 3.

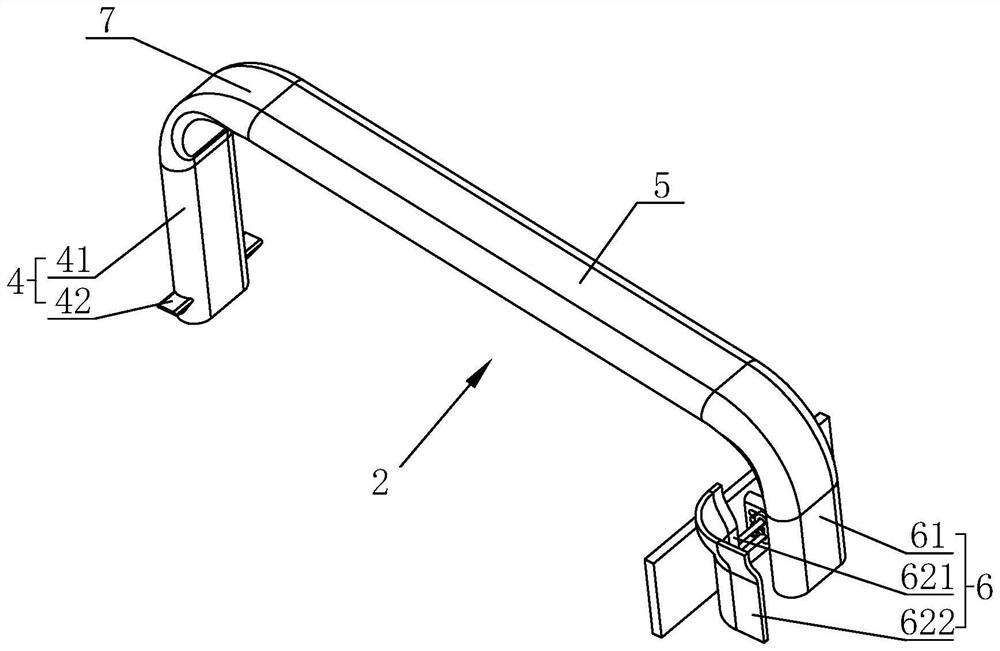

[0034] as Figure 2 It is shown in the structural diagram of the conveyor 2. The conveyor 2 includes an access mechanism 4, a middle track 5 and a placement mechanism 6. The middle track 5 is connected between the access mechanism 4 and the placement mechanism 6, the access mechanism 4 is connected to the discharge end of the bending device 1, and the placement mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com