Robot workpiece automatic hanging system based on visual identification detection

A visual recognition and robot technology, applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of using multiple cameras, unstable visual recognition analysis and processing, and difficult installation space location, so as to improve the level of automation, The effect of solving deformation and offset problems, precise deformation and offset problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

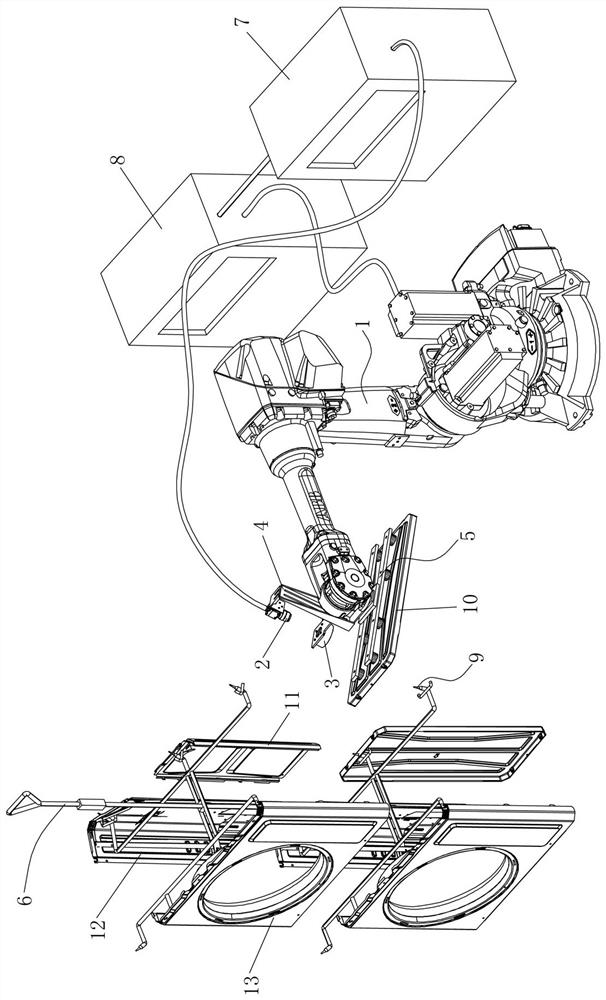

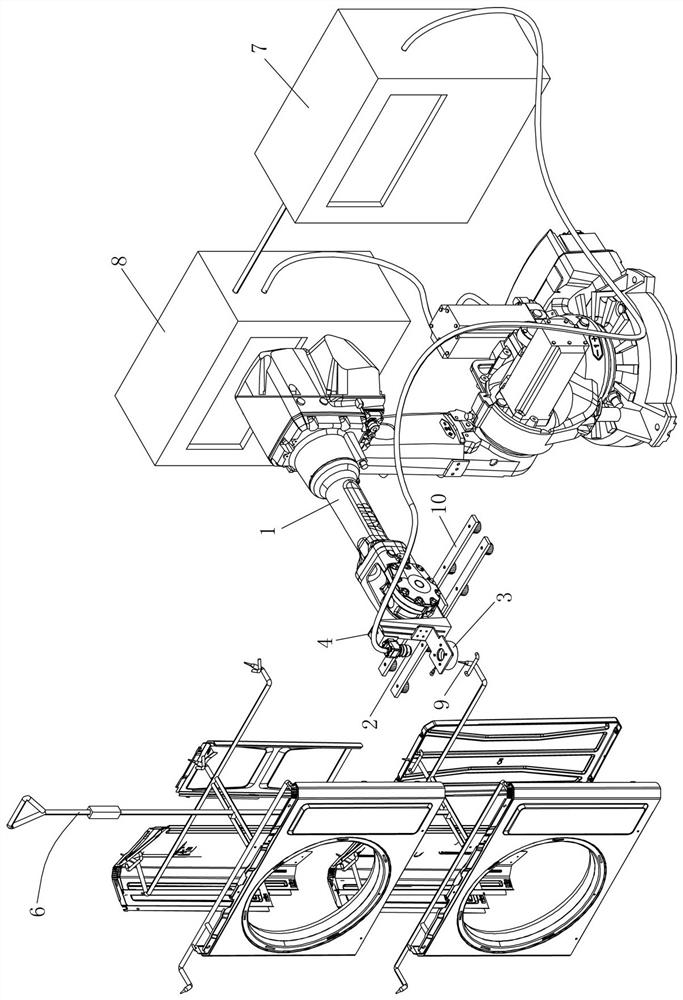

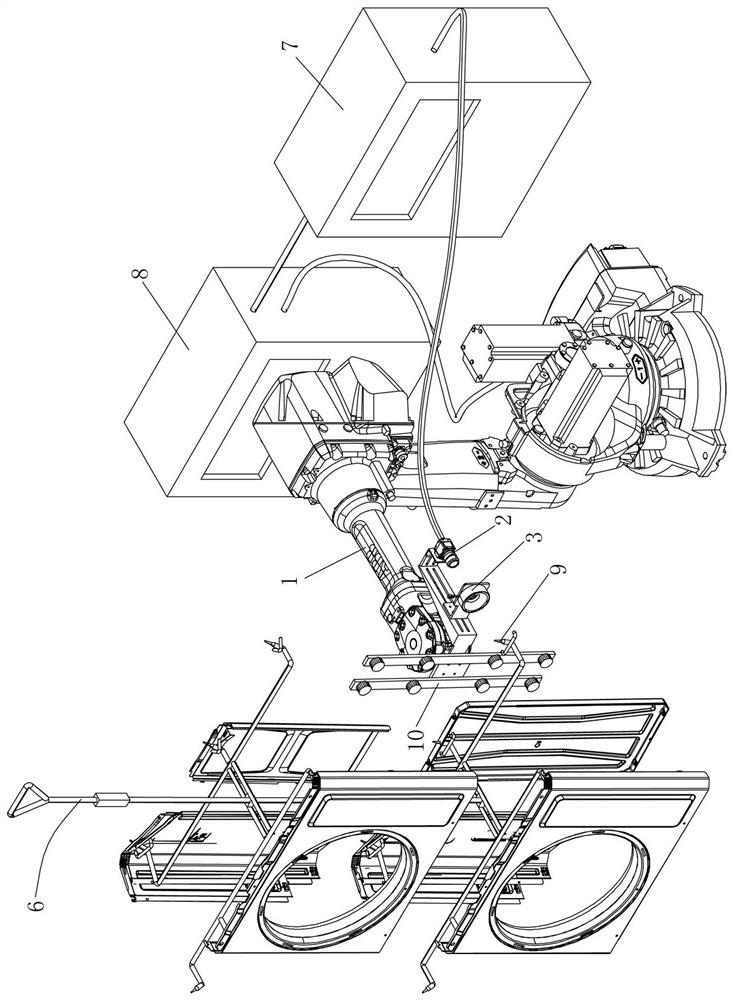

[0023] Such as Figure 1 to Figure 3 Shown is a robot workpiece automatic hanging system based on visual recognition detection, the system includes a robot arm 1, a camera 2, a light source 3, a camera bracket 4, a mechanical manual fixture 5, a workpiece hanger 6, and a visual recognition analysis system 7 And the robot control system 8, the light source 3 is a ring light source, the camera 2 adopts the model CA-H048MK camera of Japan Keyence Co., Ltd., and the visual recognition analysis system 7 adopts the vision controller model of Japan Keyence Co., Ltd. Identification analysis system.

[0024] The camera bracket 4 and the mechanical manual fixture 5 are all installed on the front end of the robot arm 1, the camera 2 is installed on the camera bracket 4, the light source 3 is also installed on the camera bracket 4, and is located in front of the camera 2, the camera 2 and the light source 3 are both It is connected with the visual recognition analysis system 7, and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com