Distributed powder spraying system and method

A distributed, powder-spraying technology, applied in the field of powder-spraying metallurgy, can solve the problems of difficulty in increasing powder-spraying points, low production efficiency, and small powder storage capacity, and achieves improved powder-spraying efficiency, increased maintenance difficulty, and powder storage capacity. And the effect of large amount of powder spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The powder spraying system of this embodiment is applied to a scrap steel continuous preheating electric arc furnace, and is provided with 3 powder spraying working points (dusting working points A, B, C), and the maximum powder consumption is 2000kg / furnace.

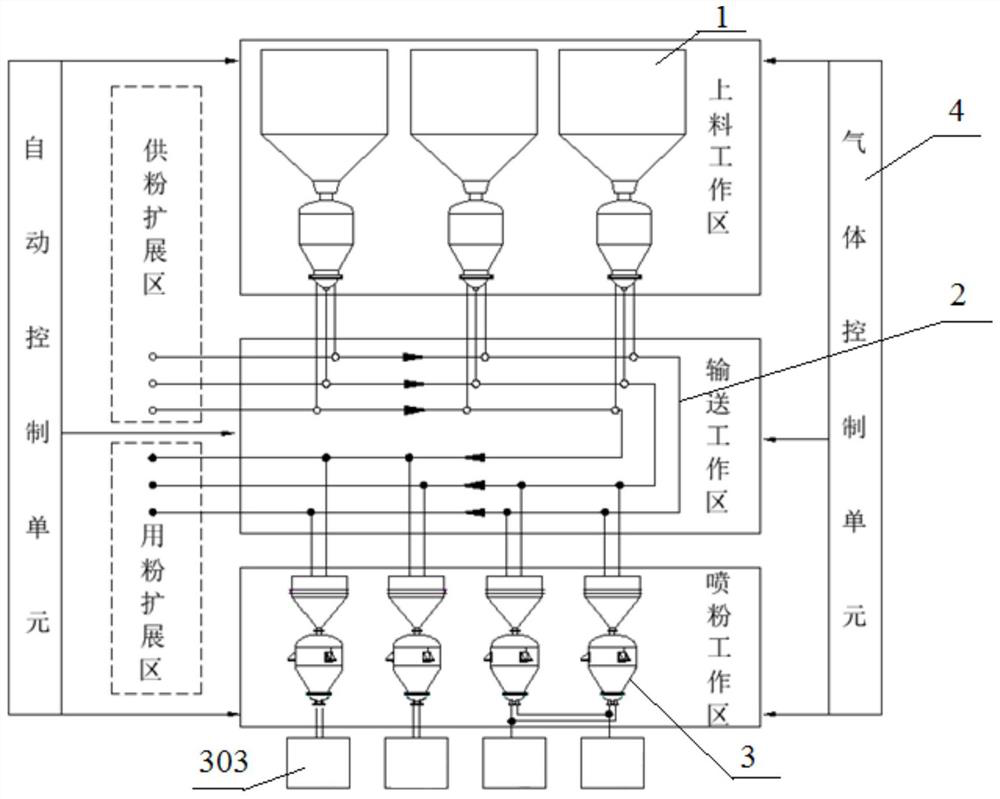

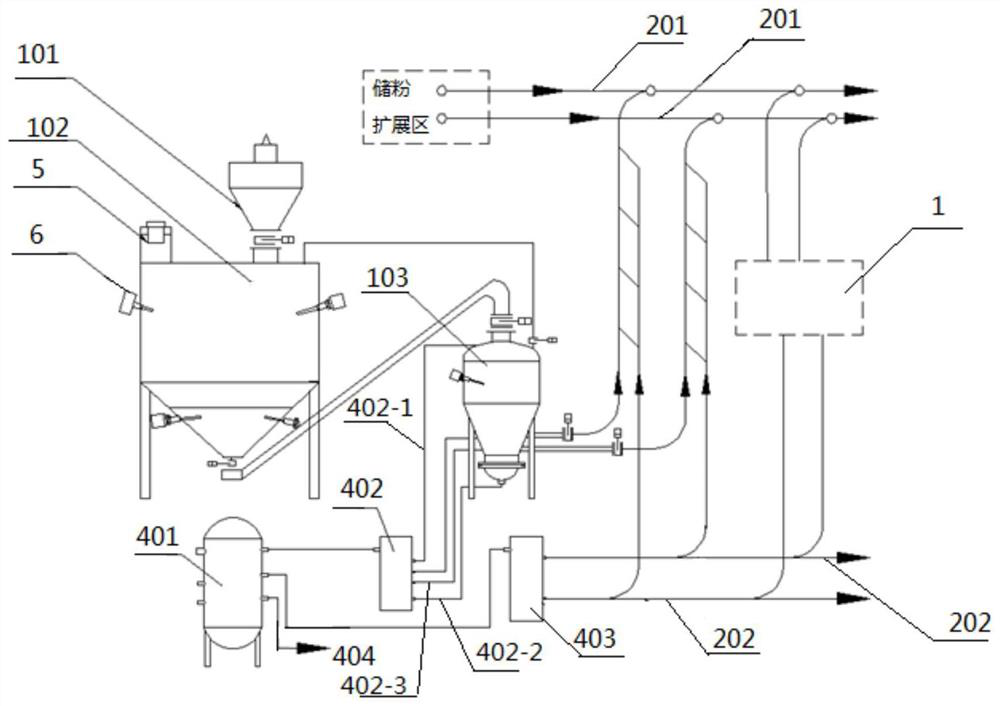

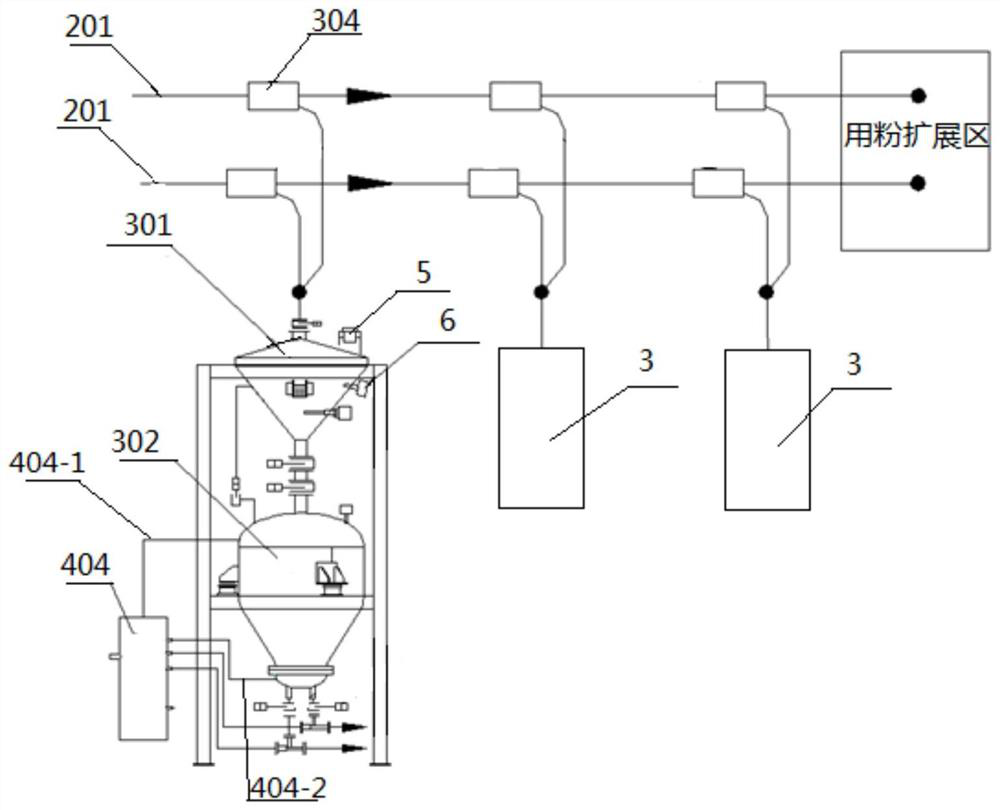

[0085] powder spraying system (such as Figure 6 Shown) includes 2 storage modules (storage modules A, B), 2 delivery modules (delivery modules A, B), and 3 powder spraying modules (powder spraying modules A, B, C). Distributed layout design is carried out according to the process requirements. The material storage module is located 100 meters away from the powder spraying point of the furnace. The powder spray module is located near the electric arc furnace on the electric arc furnace platform. The sending device of each material storage module communicates with each The powder conveying main pipeline of each conveying module is connected, and a valve is set on the pipeline between the sending device and the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com