Device and method for extracting gold from gold concentrate through non-cyanide leaching

A gold concentrate and leaching technology, applied in the field of gold concentrate, can solve the problems of easily corroded equipment, human health impact, high toxicity of chemicals, etc., and achieve the effects of less corrosiveness, simple structure and less toxicity of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

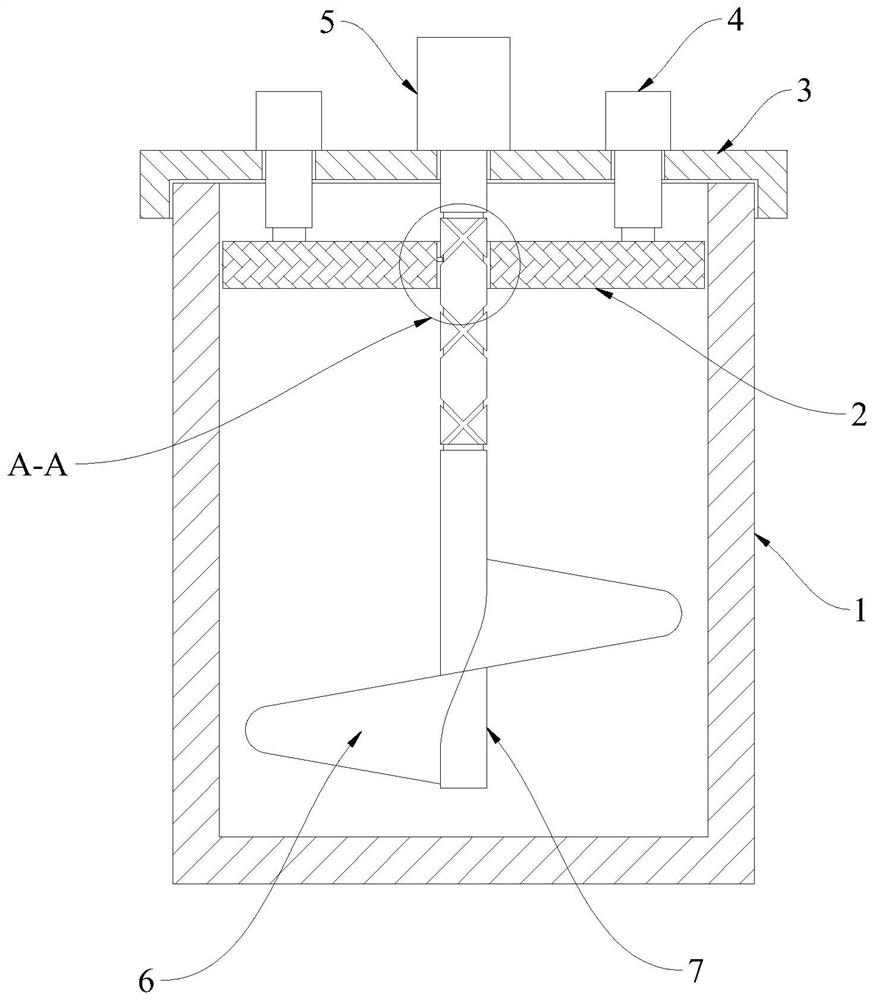

[0031] The method for extracting gold by non-cyanide leaching of gold concentrate proposed by the present invention has the following steps:

[0032] S1: The gold concentrate is ball milled, and at least 90% of the gold concentrate particle size after ball milling is less than 200 mesh;

[0033] S2: Add the gold concentrate ball-milled in S1 into the tank, and add leachate into the tank at the same time, the mass-volume ratio of the gold concentrate to the leachate is 1g:3mL;

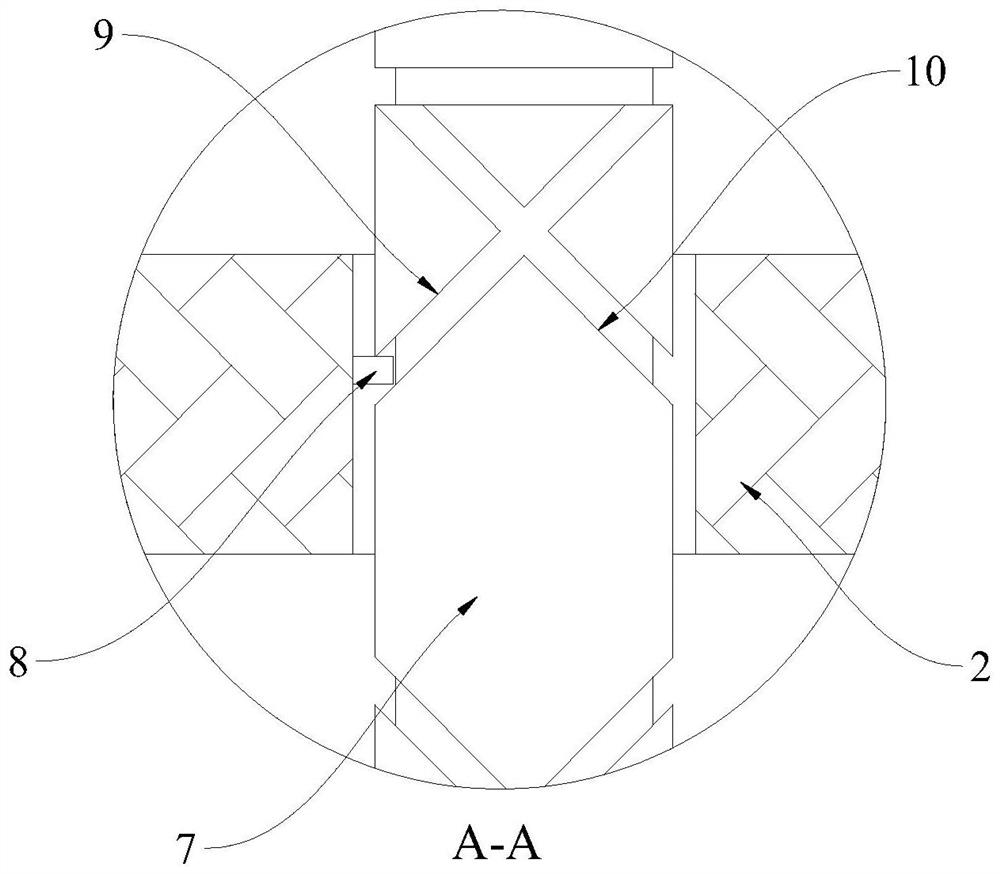

[0034] S3: The rotation of the stirring shaft is controlled by the drive motor, and the stirring shaft drives the material to rotate. At the same time, the pressure regulating plate moves back and forth along the reversing thread on the stirring shaft to achieve the purpose of continuously adjusting the pressure in the tank. The maximum pressure in the adjusted tank is 0.5 MPa;

[0035] S4: During the leaching process, the tank body is heated to the preset temperature through the heating module, then t...

Embodiment 2

[0040] The method for extracting gold by non-cyanide leaching of gold concentrate proposed by the present invention has the following steps:

[0041] S1: The gold concentrate is ball milled, and at least 90% of the gold concentrate particle size after ball milling is less than 200 mesh;

[0042] S2: Add the gold concentrate ball-milled in S1 into the tank, and add leachate into the tank at the same time, the mass-volume ratio of the gold concentrate to the leachate is 1g:2mL;

[0043] S3: The rotation of the stirring shaft is controlled by the drive motor, and the stirring shaft drives the material to rotate. At the same time, the pressure regulating plate moves back and forth along the reversing thread on the stirring shaft to achieve the purpose of continuously adjusting the pressure in the tank. The maximum pressure in the adjusted tank is 0.4 MPa;

[0044] S4: During the leaching process, the tank body is heated to the preset temperature through the heating module, then t...

Embodiment 3

[0049] The method for extracting gold by non-cyanide leaching of gold concentrate proposed by the present invention has the following steps:

[0050] S1: The gold concentrate is ball milled, and at least 90% of the gold concentrate particle size after ball milling is less than 200 mesh;

[0051] S2: Add the gold concentrate ball-milled in S1 into the tank, and add leachate into the tank at the same time, the mass-volume ratio of the gold concentrate to the leachate is 1g:4mL;

[0052] S3: The rotation of the stirring shaft is controlled by the drive motor, and the stirring shaft drives the material to rotate. At the same time, the pressure regulating plate moves back and forth along the reversing thread on the stirring shaft to achieve the purpose of continuously adjusting the pressure in the tank. The maximum pressure in the adjusted tank is 0.6 MPa;

[0053] S4: During the leaching process, the tank body is heated to the preset temperature through the heating module, then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com