Static pressure pipe pile with high bearing capacity

A technology of static pressure pipe and bearing capacity, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve problems such as poor penetration rate, reduced service life of pipe string, and crack of pipe string, so as to reduce energy loss, The effect of increasing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

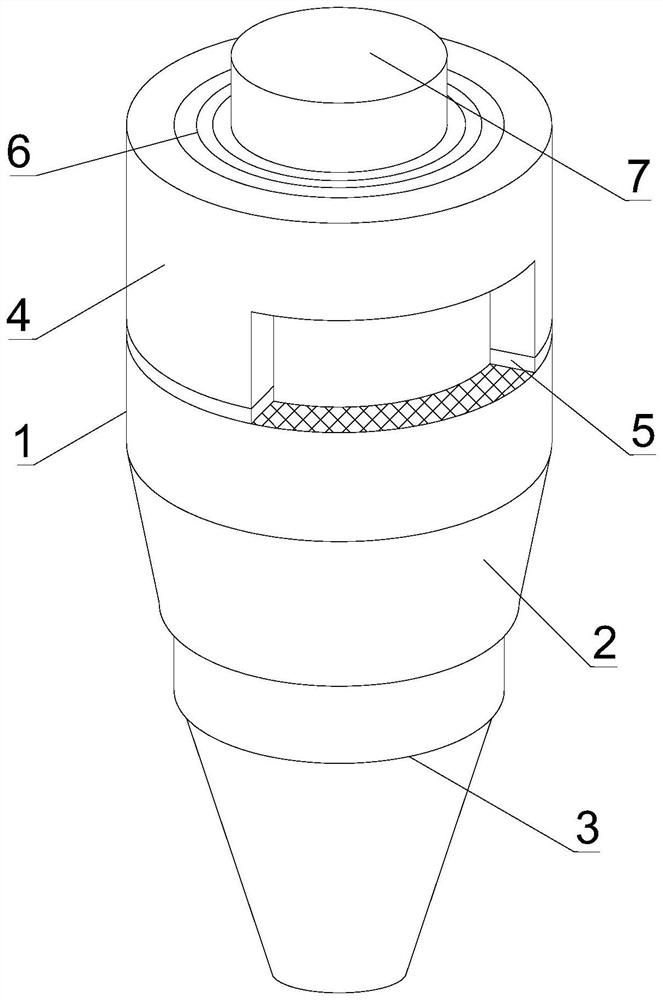

[0040] Such as Figure 1-7As shown, the present invention provides a static pressure pipe pile with high bearing capacity, which includes a load-bearing static pressure column 1. The soil-breaking cone head 3, the top outer surface of the pressure-resistant pipe column body 2 is coated with a butt joint sealing soft rubber 5, the top outer surface of the butt joint sealing soft rubber 5 is provided with a casing 4, and the top inner outer surface of the casing 4 is provided with a The wear-resistant and waterproof ferrule 6, the soil-breaking cone 3, the pressure-resistant pipe column body 2, the casing 4 and the wear-resistant waterproof ferrule 6 are provided with a high-strength cement pouring body 7 on the inner and outer surfaces of the wear-resistant and waterproof ferrule 6, and the pressure-resistant pipe column body 2 includes Expansion extrusion block 28 .

[0041] In this embodiment, a pile driver is used to drive the soil-breaking cone head 3 into a suitable posit...

Embodiment 2

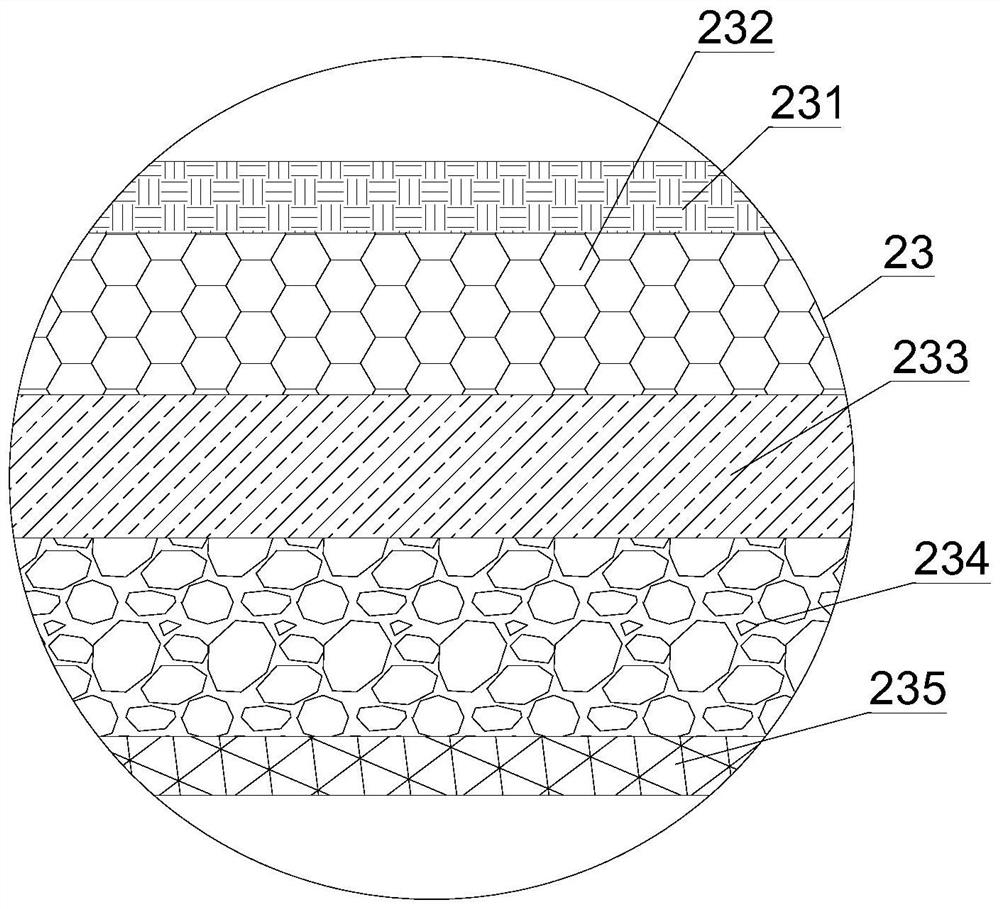

[0043] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a butt joint groove 2 31 is provided on the top outer surface of the soil-breaking cone head 3, and a butt joint groove 2 31 is provided on the inner and outer surface of the butt joint groove 2 31. There is a wear-resistant and anti-falling butt joint layer 32, a trapezoidal cavity 33 is arranged on the bottom inner surface of the soil-breaking cone head 3, and a trapezoidal compression support column 34 is fixedly connected to the top inner surface of the trapezoidal cavity 33, and the trapezoidal compression support column 34 Fixedly connected with trapezoidal casing 35 on both sides of the bottom end, on the top inner surface of trapezoidal casing 35 and on the bottom outer surface of breaking soil cone 3, be provided with broken cone 36.

[0044] In this embodiment, equipment is used to drive the soil-breaking cone 3 into the ground, cooperat...

Embodiment 3

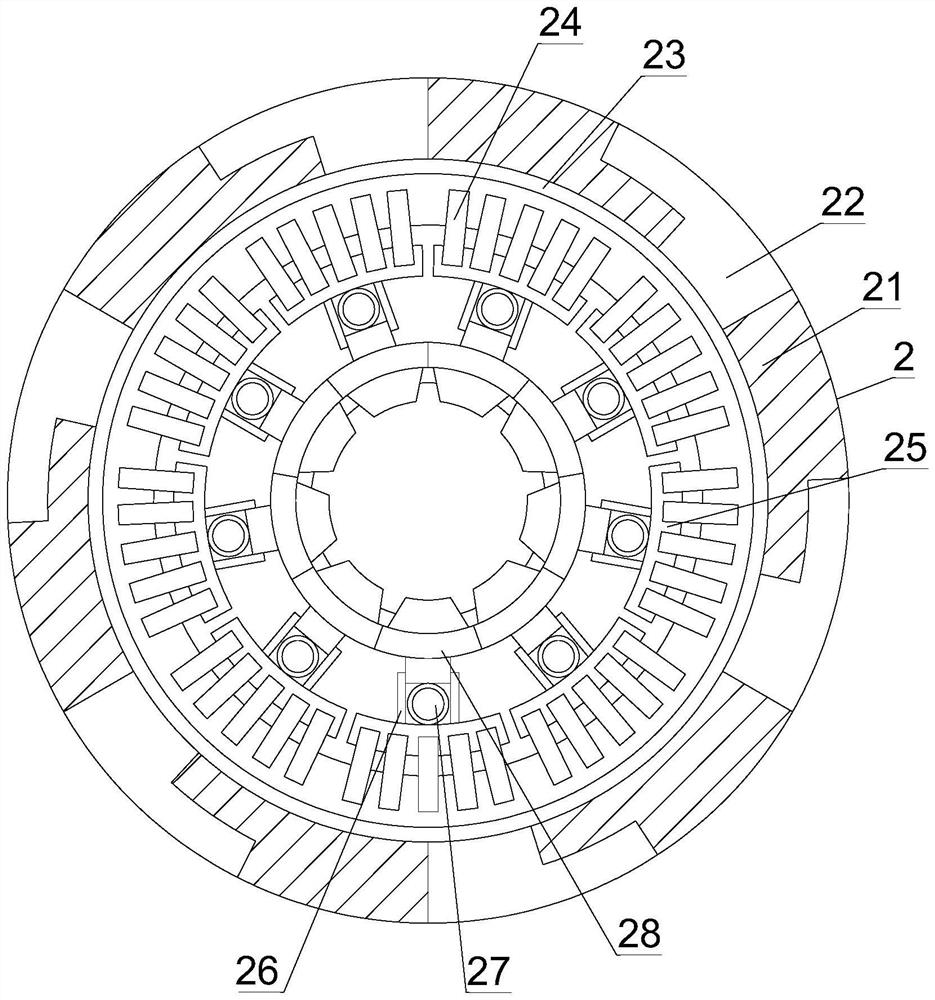

[0046] Such as Figure 1-7 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, a butt joint groove 21 is provided on the top outer surface of the pressure-resistant pipe body 2, and the inside and outside of the pressure-resistant pipe body 2 The surface is provided with a compression protection layer 23, and the inner surface of the compression protection layer 23 is provided with a clamping anti-shattering steel nail 24, and one end of the clamping anti-shattering steel nail 24 is fixedly connected with an arc-shaped butt plate 25, the arc-shaped The outer surface of the docking plate 25 is fixedly connected with a partition 26, the outer surface of the arc-shaped docking plate 25 is provided with an expansion high elastic ring 27, and the outer surface of one end of the expansion extrusion block 28 is connected to the outer surface of the expansion high elastic ring 27 The inner surfaces of both sides of the casing 4 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com