White-light-permeable composite film layer as well as preparation method and application thereof

A composite film layer and white light technology, which is applied in optics, optical components, instruments, etc., can solve the problems that cannot be satisfied, the vacuum degree of the coating film and the evaporation parameters of the coating film cannot meet the white light of the PVD indium-coated layer, and there is no high-grade silver-colored texture of metal plating, etc. To achieve a variety of structural effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

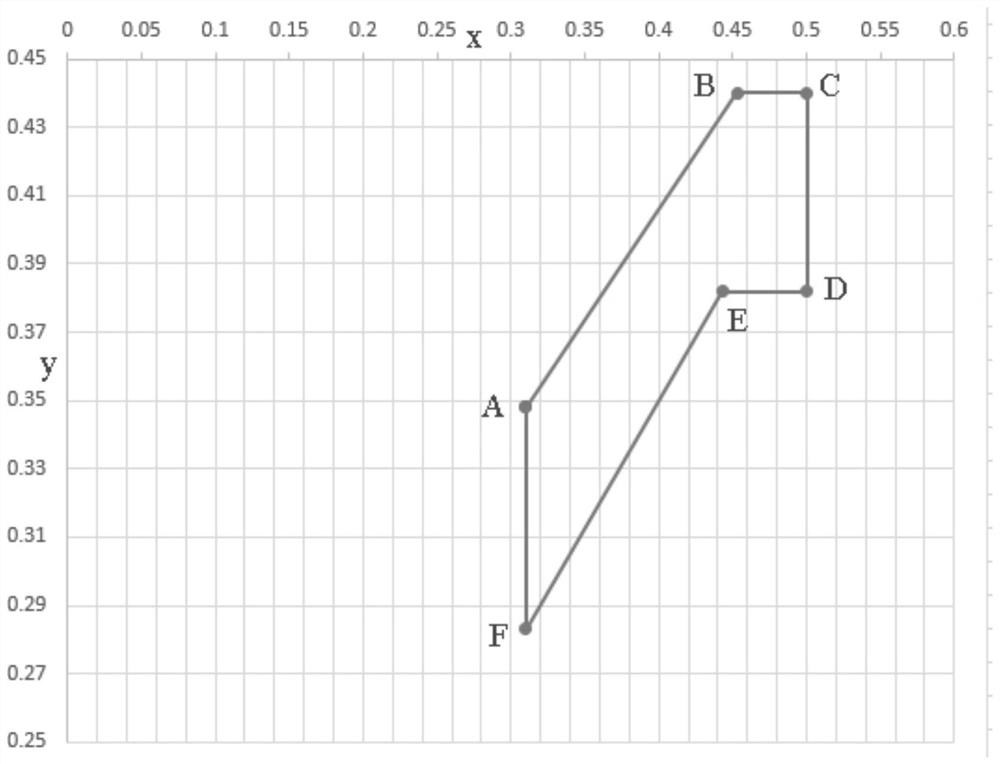

Image

Examples

preparation example Construction

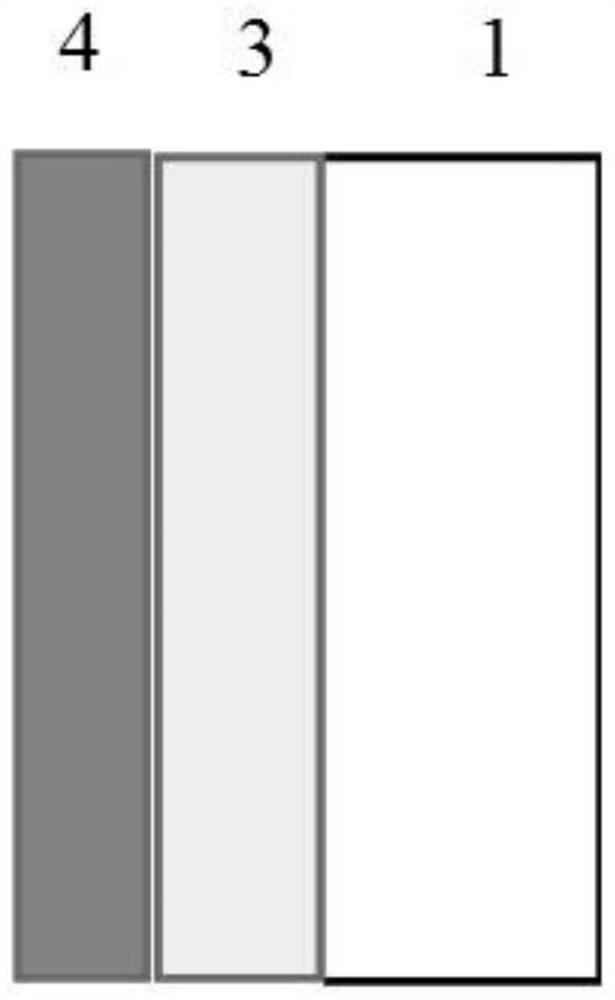

[0054] The preparation method of the composite film layer that can transmit white light comprises the following steps:

[0055] Mix transparent plastic with blue pigment and purple pigment (add 0.5-8 parts of blue pigment and 0-2 parts of purple pigment to 100 parts of transparent plastic), and inject to form transparent panel 1;

[0056] On one side of the transparent panel 1, indium plating is evaporated by physical vapor deposition (PVD) to form an indium plating layer 3;

[0057] A transparent paint is coated on the indium-plated layer 3 to form a transparent paint layer 4, that is, a composite film layer that can transmit white light is obtained.

[0058] Examples of transparent plastics are polycarbonate, PVC, PET or PP transparent plastics.

[0059] The transparent coating that forms the transparent coating layer is a mixture of transparent, liquid epoxy resin or acrylic resin as the main component, which can be used in various coating processing operations. to the pr...

Embodiment 1

[0074] The preparation method of the white light-permeable composite film layer of this embodiment is specifically as follows:

[0075] Mix 100 parts of transparent polycarbonate plastic and 4 parts of sky blue pigment (average particle size is 300nm) with CMYK value of C45 M10 Y10K0, and inject to form a transparent panel with a thickness of 5mm;

[0076] On one side of the transparent panel, evaporate indium plating by physical vapor deposition to form a PVD indium plating layer with a thickness of 18nm;

[0077] The transparent paint is sprayed on the PVD indium-plated layer, and after curing, a transparent paint layer with a thickness of 20 μm is formed to obtain a white light-transmitting composite film layer.

Embodiment 2

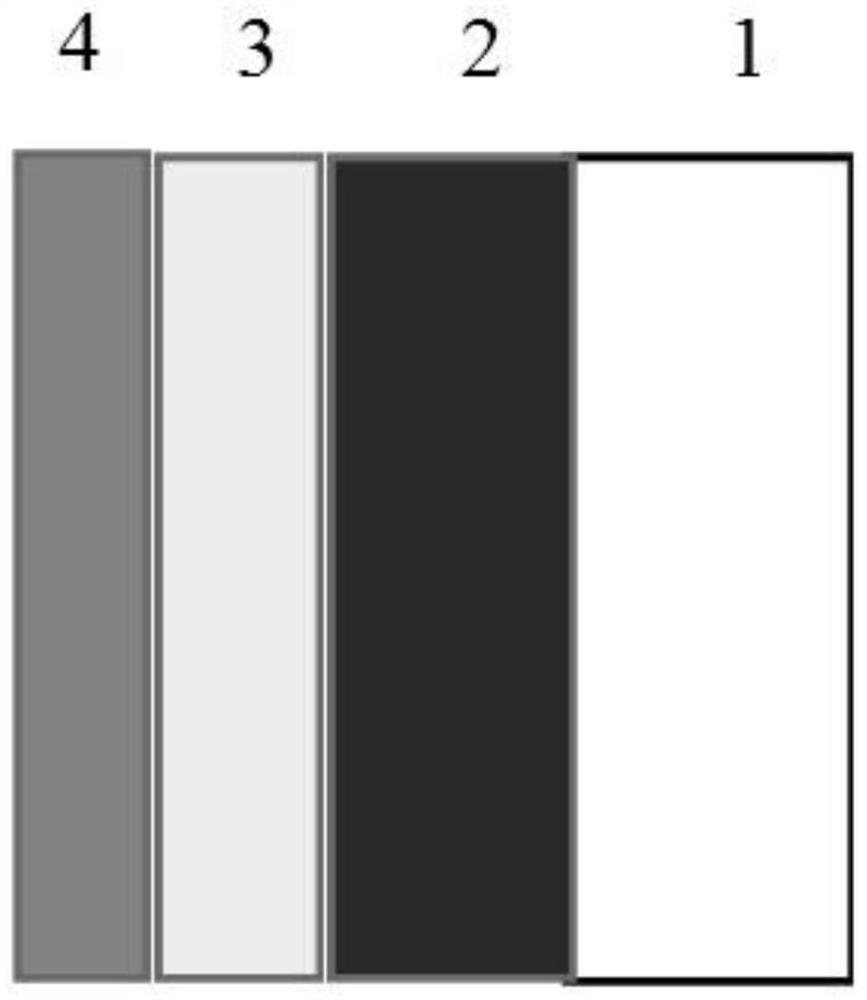

[0079] The preparation method of the white light-permeable composite film layer of this embodiment is specifically as follows:

[0080] Mix 100 parts of transparent polycarbonate plastic, 3 parts of azure pigment (average particle size 500nm) with CMYK value of C70 M10 Y0 K0 and 0.5 parts of maroon pigment (average particle size of 400nm) with CMYK value of C45 M70Y50 K0 , injection molding to form a transparent panel with a thickness of 7mm;

[0081] Spray transparent primer slurry on one side of the transparent panel, and form a transparent primer layer with a thickness of 20 μm after curing;

[0082] Evaporate indium plating on the transparent primer layer by physical vapor deposition to form a PVD indium plating layer with a thickness of 25nm;

[0083] The transparent paint is sprayed on the PVD indium plating layer, and after curing, a transparent paint layer with a thickness of 25 μm is formed to obtain a white light-transmitting composite film layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap