Pyrolysis processing device and method for preparing biochar by recycling waste

A waste recycling and processing device technology, applied in grain processing, petroleum industry, special dry distillation, etc., can solve problems such as excessive pyrolysis, retention, waste of energy, etc., achieve high-efficiency pyrolysis, improve efficiency, and avoid excessive heat solution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

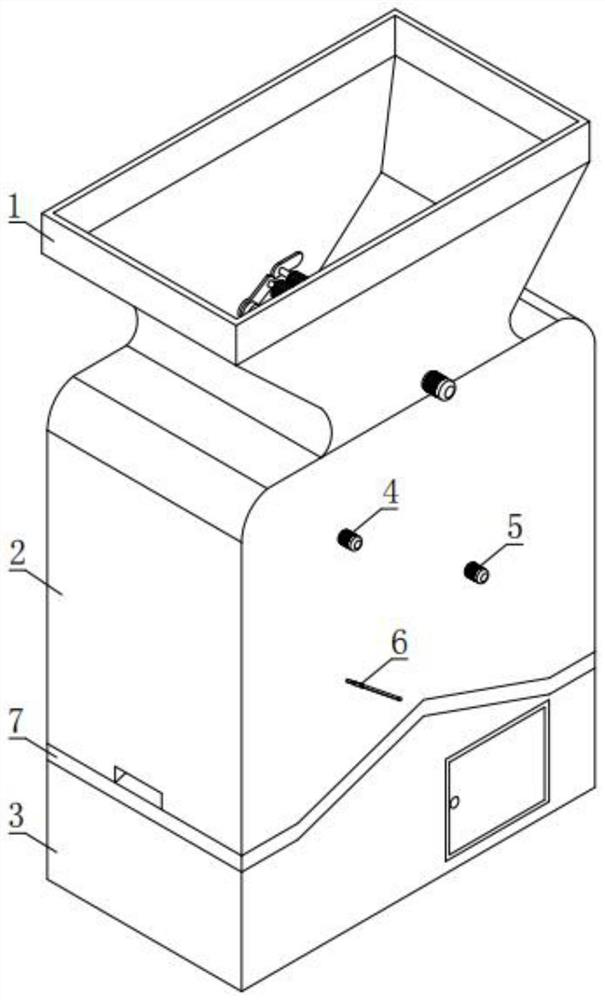

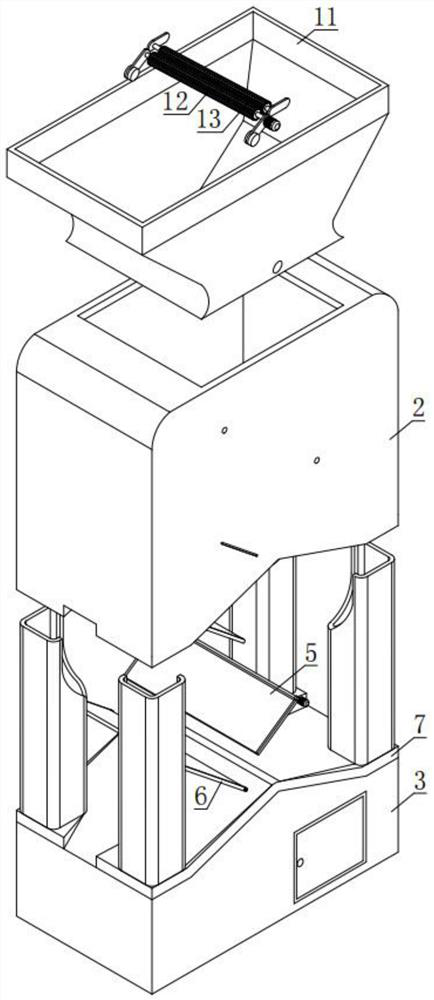

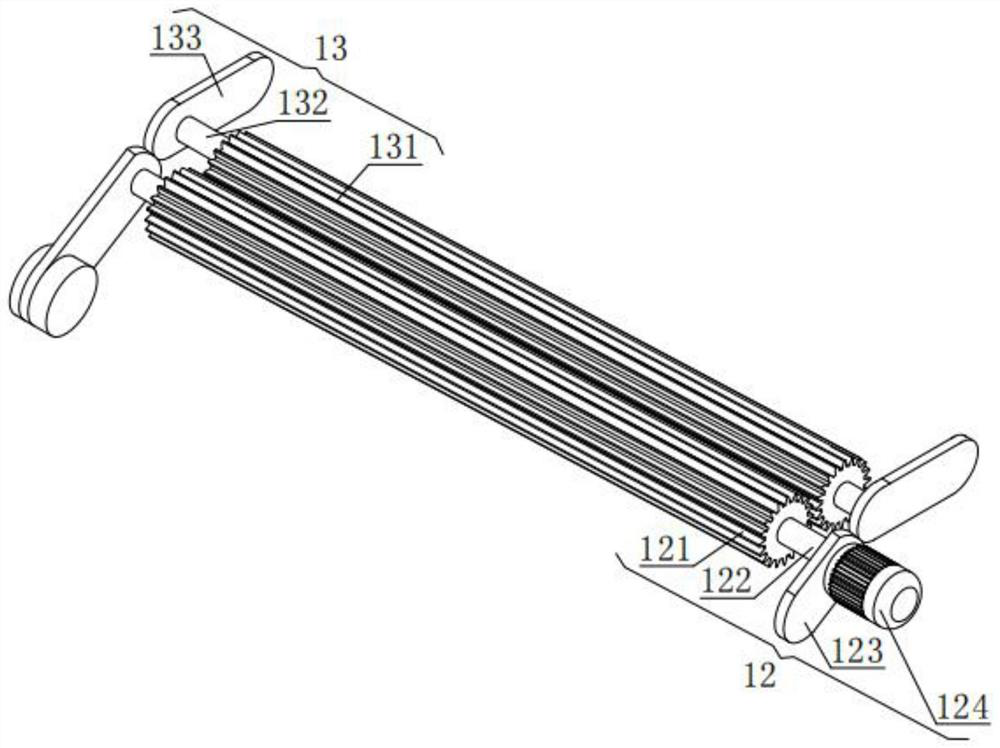

[0037] refer to figure 1 , a pyrolysis processing device for preparing biochar for waste recycling, comprising a feed mechanism 1, a pyrolysis shell 2, a pyrolysis base 3, a first catalytic assembly 4, a second catalytic assembly 5, a material distribution assembly 6 and a pyrolysis Platform 7, the pyrolysis shell 2 is double-layered, and its interior is hollow to form a cavity filled with molten salt. The molten salt is used as a heat exchange medium to provide a carrier for the secondary utilization of heat, and the pyrolysis shell 2 The inner layer is a heat conducting layer, the outer layer of the shell is an insulating layer, the upper end of the pyrolysis shell 2 is equipped with a feeding mechanism 1, and the middle part of the pyrolysis shell 2 is equipped with a pyrolysis platform 7, and the pyrolysis platform The lower end of 7 is equipped with a pyrolysis base 3, and the cavity between the pyrolysis platform 7 and the pyrolysis shell 2 is sequentially provided with ...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that the structure of the material distribution assembly 6 is different. In this embodiment, the steel baffle plate 61 and the material distribution side plate 62 are slidingly connected. By loosening the bolts on the L-shaped handle 63, Pull the L-shaped handle 63 again, the position of the steel baffle 61 can be moved along the strip hole 64 on the material distribution side plate 62, and then adjust the distance between the steel baffle 61 and the raised top of the pyrolysis platform 7, and then Regulate the size of the carbon that can be discharged along the outlet on the left side of the pyrolysis platform 7;

[0049] refer to Figure 8 to Figure 9 , the material distribution assembly 6 includes a steel baffle 61 and a material distribution side plate 62, the middle part of the side wall of the steel baffle 61 is fixedly connected with an L-shaped handle 63, and the material distribution side plate 62 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com