Catalytic conversion method for preparing light olefins and aromatic hydrocarbons from biological oil

A catalytic conversion method and technology of bio-oil, which is applied in the field of catalytic conversion of bio-oil, can solve the problems of insufficient and effective use of straight-chain hydrocarbon groups, and achieve the effect of high bio-oil conversion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

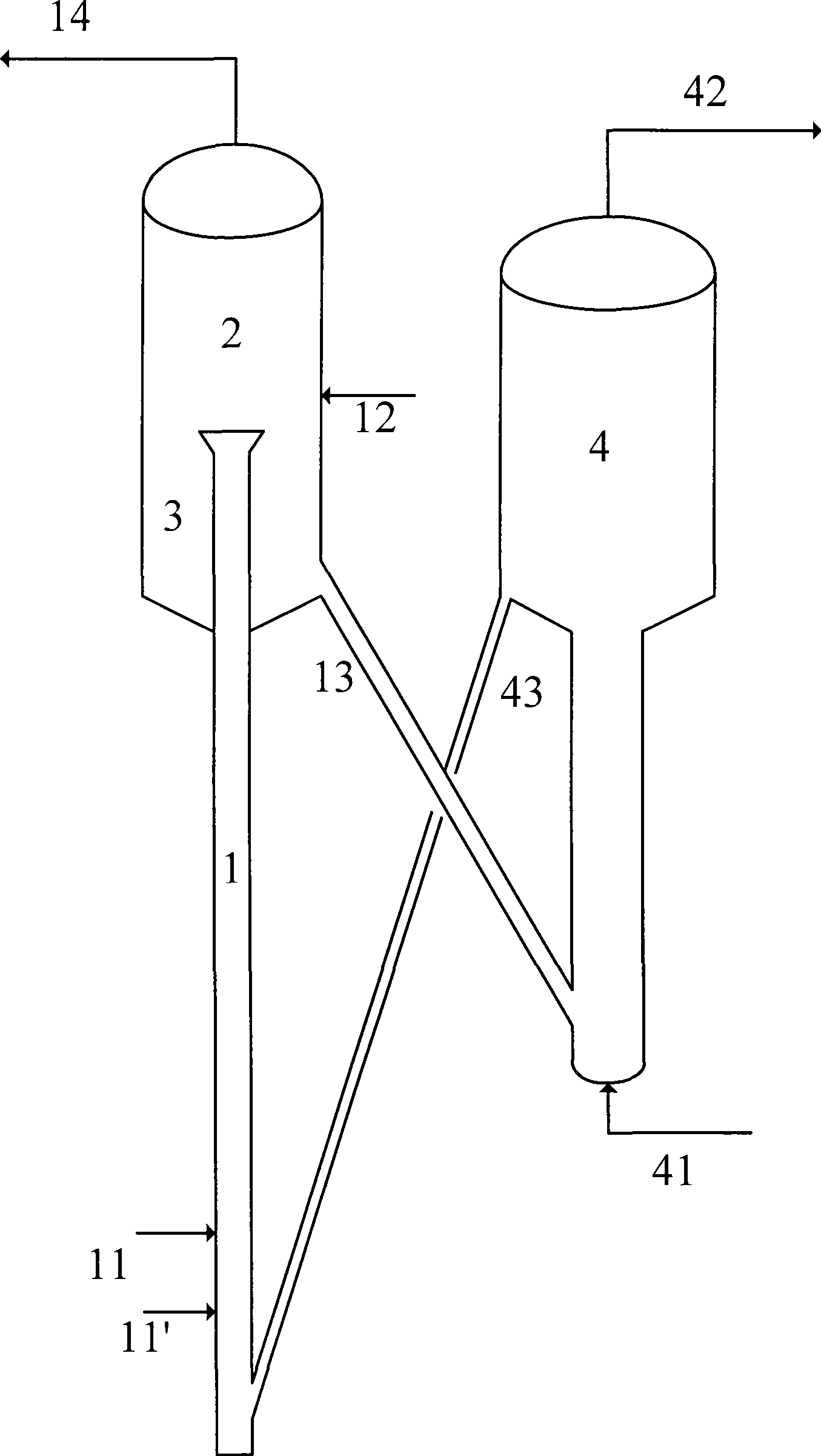

Method used

Image

Examples

Embodiment 1~4

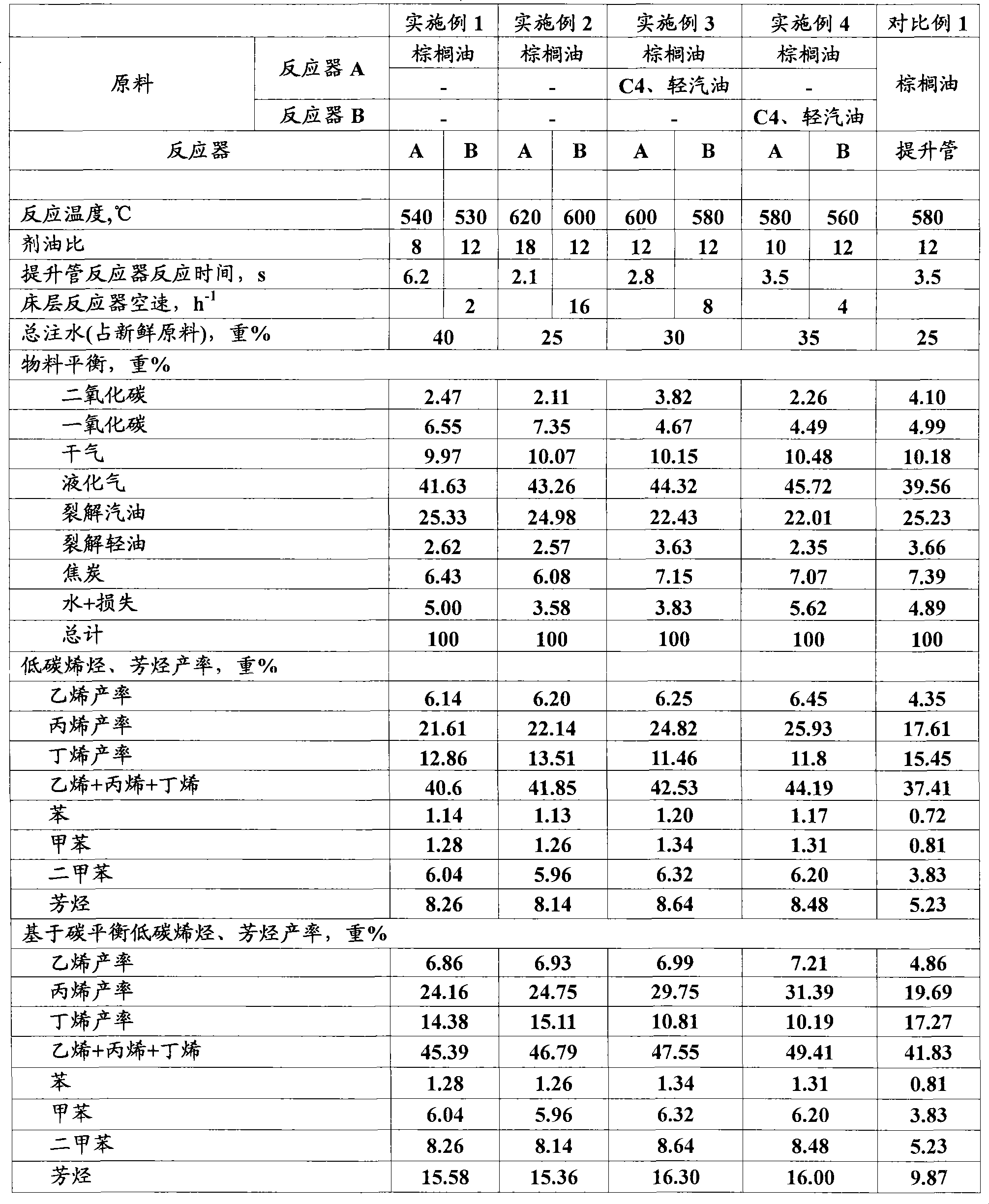

[0042] Examples 1-4 illustrate the effect of using the bio-oil catalytic conversion method provided by the present invention.

[0043] The catalyst (containing 10% by weight of zeolite beta, 20% by weight of ZSM-5 zeolite, and the balance as a carrier, all based on the total weight of the catalyst) was aged at 800°C with 100% steam for 10 hours, using a medium-sized test device, compounded The catalyst loading in the reactor was 60 kg.

Embodiment 1

[0044] Adopt the compound reactor of riser+fluidized bed in embodiment 1, palm oil only enters riser reactor 1;

Embodiment 2

[0045] In the embodiment 2, the composite reactor of riser+fluidized bed is adopted, palm oil enters riser reactor 1, and back refining C4 and light gasoline components also enter riser reactor 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com