Method for preparing bio-oil by catalytic pyrolysis of microalgae with high fat content by molecular sieve

A technology of catalytic pyrolysis and molecular sieve, which is used in biological raw materials, catalytic cracking, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of high energy consumption and high operating costs of fluidized bed reactors, and achieve low energy consumption and good market application. Prospect, Yield and High Quality Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Nannochloropsis was collected, dried, crushed and sieved, and the microalgae powder with a particle size of less than 0.45mm was taken as the experimental raw material.

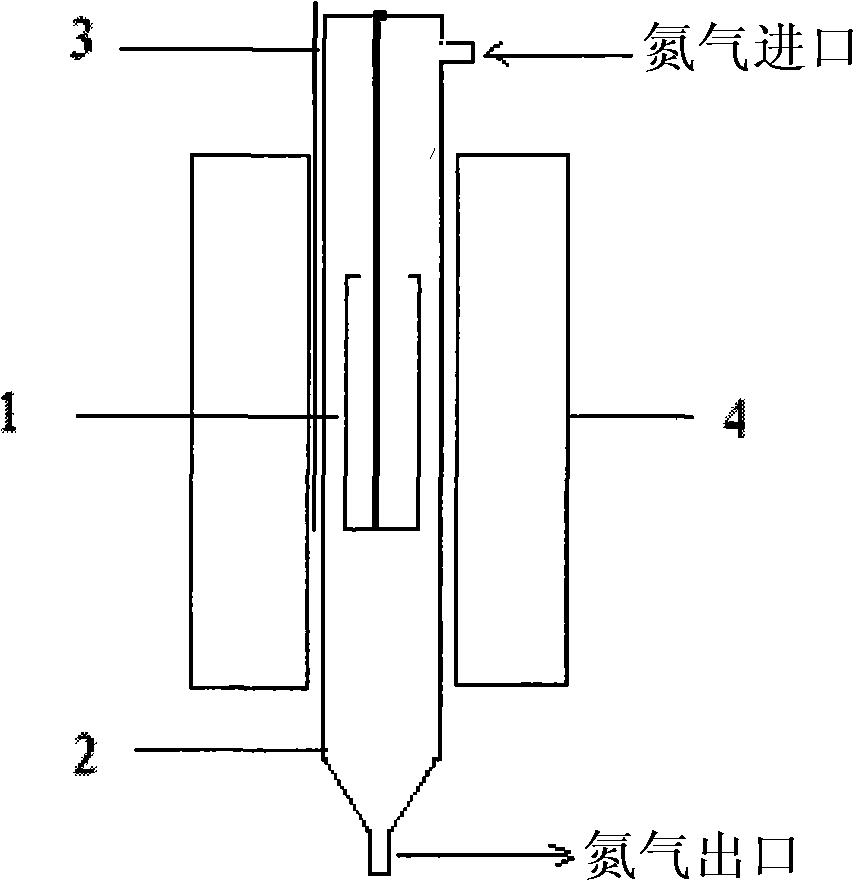

[0013] Take 1 gram of Nannochloropsis powder, fully mix it with 0.5 gram of HZSM-5 (microalgae powder: HZSM-5=2:1), and put it into a fixed-bed reactor. Nitrogen was used as the carrier gas, and the flow rate of the carrier gas was controlled at 30ml / min. Using an external electric furnace as a heat source, the descending fixed-bed reactor was raised from room temperature to 300°C at a rate of 10°C / min, and kept at this temperature for 1 hour. The gas generated in the reaction is taken out of the reactor by the carrier gas, and condensed in the condenser to obtain bio-oil. Finally, a bio-oil yield of 32% (mass fraction) was obtained.

Embodiment 2

[0015] Take 1 gram of Nannochloropsis powder, fully mix it with 0.75 gram of HZSM-5 (microalgae powder: HZSM-5=4:3), and put it into a fixed-bed reactor. Nitrogen was used as the carrier gas, and the flow rate of the carrier gas was controlled at 30ml / min. Using an external electric furnace as a heat source, the descending fixed-bed reactor was raised from room temperature to 400°C at a rate of 10°C / min, and kept at this temperature for 1 hour. The gas generated in the reaction is taken out of the reactor by the carrier gas, and condensed in the condenser to obtain bio-oil. Finally, a bio-oil yield of 53% (mass fraction) was obtained.

Embodiment 3

[0017] Take 1 gram of Nannochloropsis powder, fully mix it with 1 gram of HZSM-5 (microalgae powder: HZSM-5=1:1), and put it into a fixed-bed reactor. Nitrogen was used as the carrier gas, and the flow rate of the carrier gas was controlled at 40ml / min. Using an external electric furnace as a heat source, the descending fixed-bed reactor was raised from room temperature to 500°C at a rate of 10°C / min, and kept at this temperature for 1 hour. The gas generated in the reaction is taken out of the reactor by the carrier gas, and condensed in the condenser to obtain bio-oil. Finally, a bio-oil yield of 41% (mass fraction) was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com