Process of preparing rich furol biological oil by biomass microwave catalytic pyrolysis

A microwave catalysis and biomass technology, which is used in the preparation of liquid hydrocarbon mixtures and the petroleum industry, can solve the problems of polluted environment, low product yield, long reaction time, etc., and achieves high utilization value, short reaction time, and high selection. sexually generated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

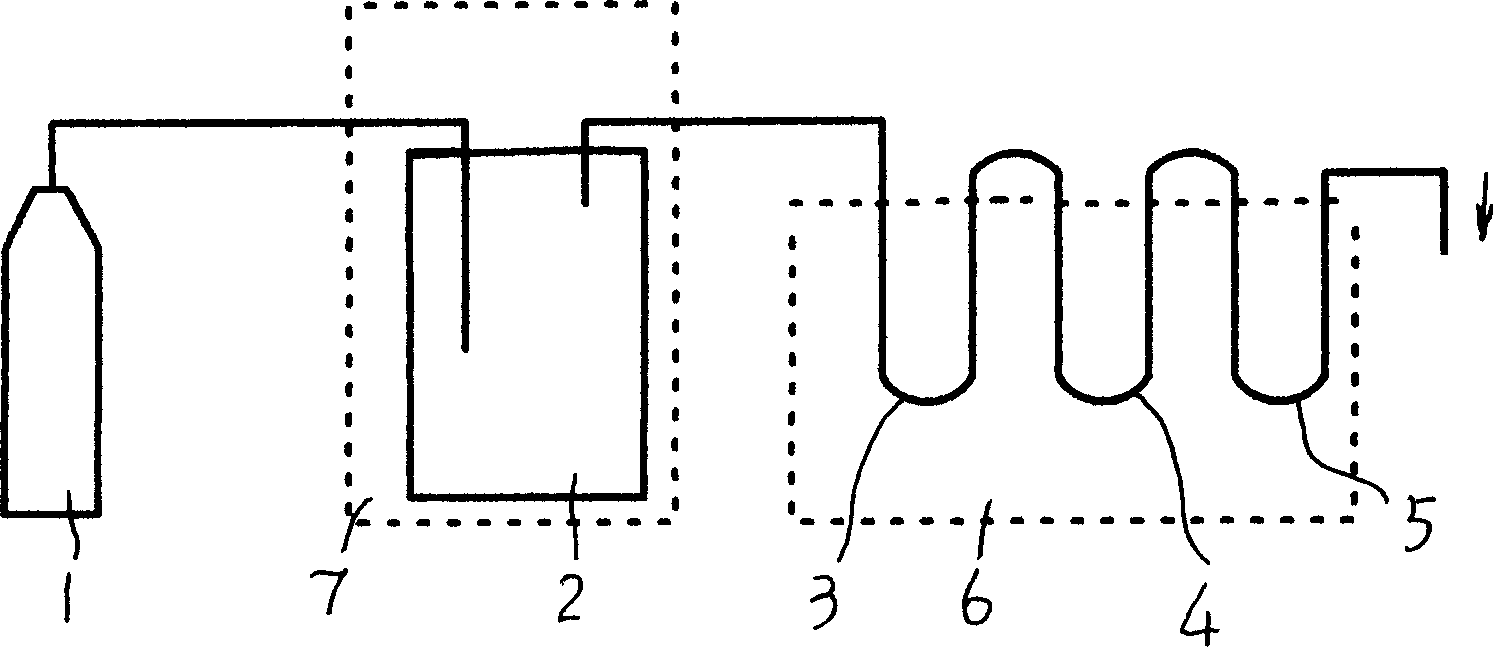

Method used

Image

Examples

Embodiment 1

[0029] Using pine sawdust as raw material, crush it to less than 1mm, and follow the above steps for raw material preparation, charging, air venting and microwave cracking. The cracking time is 12 minutes, and the liquid product is collected. The liquid product yield is 26.0%, the furfural content is 50.0%, and the water content is 27.7%.

Embodiment 2

[0031] Using cotton stalk sawdust as raw material, the same steps as in Example 1 were adopted to collect the liquid product. The liquid product yield is 18.7%, the furfural content is 36.5%, and the moisture content is 33.2%.

Embodiment 3

[0033] Using Chinese fir sawdust as raw material, adopt the same steps as in Example 1 to collect the liquid product. The liquid product yield is 24.7%, the furfural content is 43.6%, and the water content is 28.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com