Ni/Ti aperiodic multilayer film, preparation method and application thereof, and Ni/Ti aperiodic multilayer film neutron super-reflector

A non-periodic, multi-layer film technology, applied in the direction of material analysis, instruments, and measuring devices using wave/particle radiation, can solve problems such as roughness and diffusion, film microstructure and poor quality of interface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a Ni / Ti aperiodic multilayer film, comprising the following steps:

[0027] in N 2 , O 2 In a mixed atmosphere of Ar and Ar, a Ni layer is sputtered on the surface of the substrate to obtain NiN x o y layer; the value range of x is 0≤x<1, and the value range of y is 0≤y<1;

[0028] In an Ar atmosphere, the NiN x o y The Ti layer is sputtered on the surface of the layer to obtain the Ti layer;

[0029] Repeat the process of sputtering Ni layer and sputtering Ti layer to obtain the Ni / Ti aperiodic multilayer film;

[0030] The number of repetitions is ≥1.

[0031] In the present invention, unless otherwise specified, all preparation materials are commercially available products well known to those skilled in the art.

[0032] The invention is in N 2 , O 2 In a mixed atmosphere of Ar and Ar, a Ni layer is sputtered on the surface of the substrate to obtain NiN x o y layer; the value range of x is 0≤x<1, and the valu...

Embodiment 1

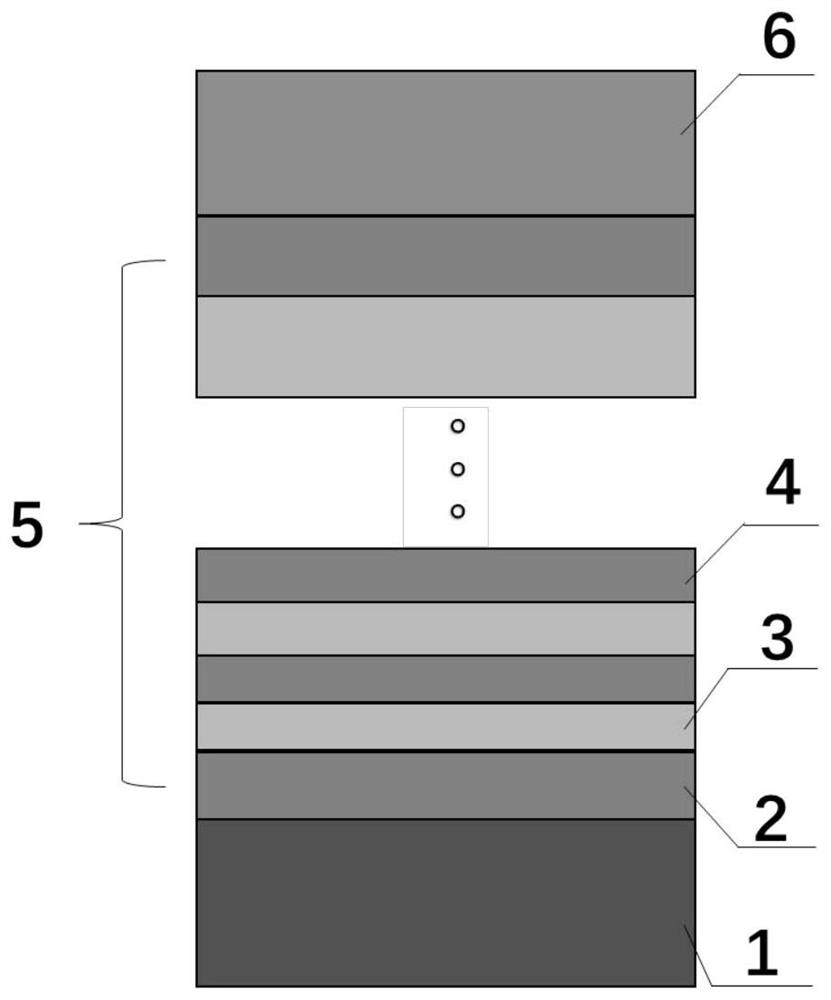

[0058] Ni / Ti aperiodic multilayer neutron superreflector:

[0059] Substrate: float glass with a thickness of 5mm;

[0060] Base layer: Ti layer with a thickness of 10nm;

[0061] Ni / Ti non-periodic multilayer film: NiN with alternate stacking arrangement x o y layer and Ti layer, the number of alternation is 90, NiN x o y The thickness of the Ti layer is 7-19nm (increase layer by layer from the inside to the outside, the thickness of the innermost layer is 7nm, and the thickness of the outermost layer is 19nm), the thickness of the Ti layer is 7-27nm (increase layer by layer from the inside to the outside, The thickness of the innermost layer is 7nm, the thickness of the outermost layer is 27nm), 0≤x<1, 0≤y<1;

[0062] Ni cap layer: Ni layer with a thickness of 50nm;

[0063] making process:

[0064] After the float glass with a thickness of 5 mm is pretreated to remove impurities on the surface, a Ti layer with a thickness of 10 nm is sputtered to obtain a bottom laye...

Embodiment 2

[0068] Ni / Ti aperiodic multilayer neutron superreflector:

[0069] Substrate bottom: float glass with a thickness of 5nm;

[0070] Base layer: Ti layer with a thickness of 10nm;

[0071] Ni / Ti non-periodic multilayer film: NiN with alternate stacking arrangement x o y layer and Ti layer, the number of alternation is 199, NiN x o y The thickness of the layer is 5-14nm (increase layer by layer from inside to outside, the thickness of the innermost layer is 5nm, the thickness of the outermost layer is 14nm), the thickness of Ti layer is 4-12nm (increase layer by layer from inside to outside, The thickness of the innermost layer is 4nm, the thickness of the outermost layer is 12nm), 0≤x<1, 0≤y<1;

[0072] Ni cap layer: a Ni layer with a thickness of 60nm;

[0073] making process:

[0074] After the float glass with a thickness of 5 mm is pretreated to remove impurities on the surface, a Ti layer with a thickness of 10 nm is sputtered to obtain a bottom layer;

[0075] On t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| interface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com