Multifunctional surface cleaning machine with good exhaust effect

A multi-functional, cleaning machine technology, applied to cleaning equipment, exhaust diffuser, vacuum cleaners, etc., can solve problems such as abnormal work, affecting the electrical connection of suction source components, vibration of suction source components, etc., to improve efficiency and reduce The danger of people blowing, the effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

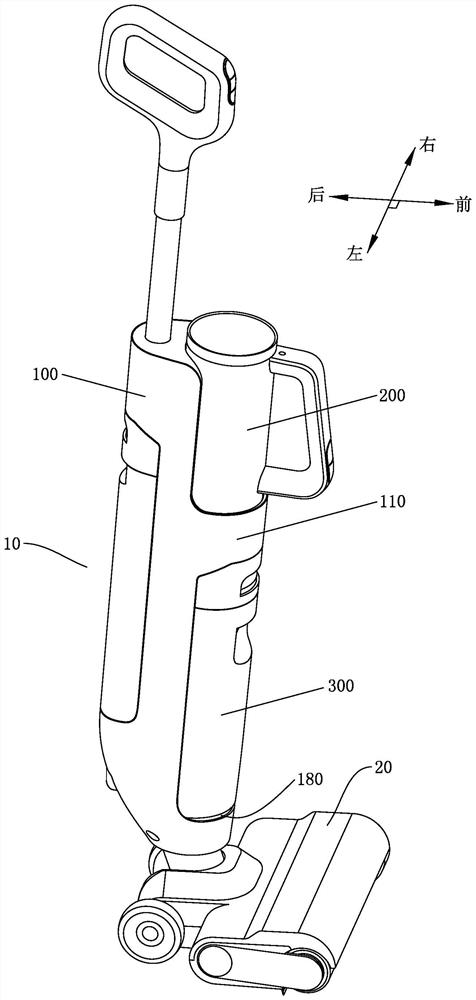

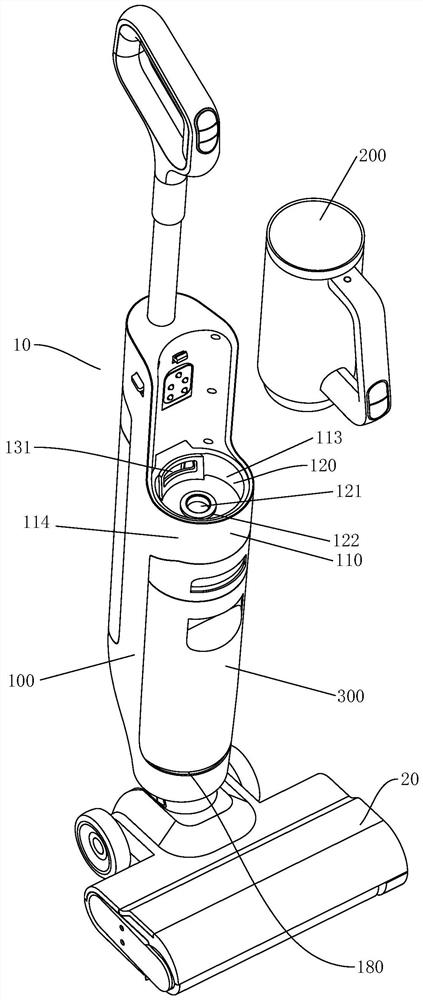

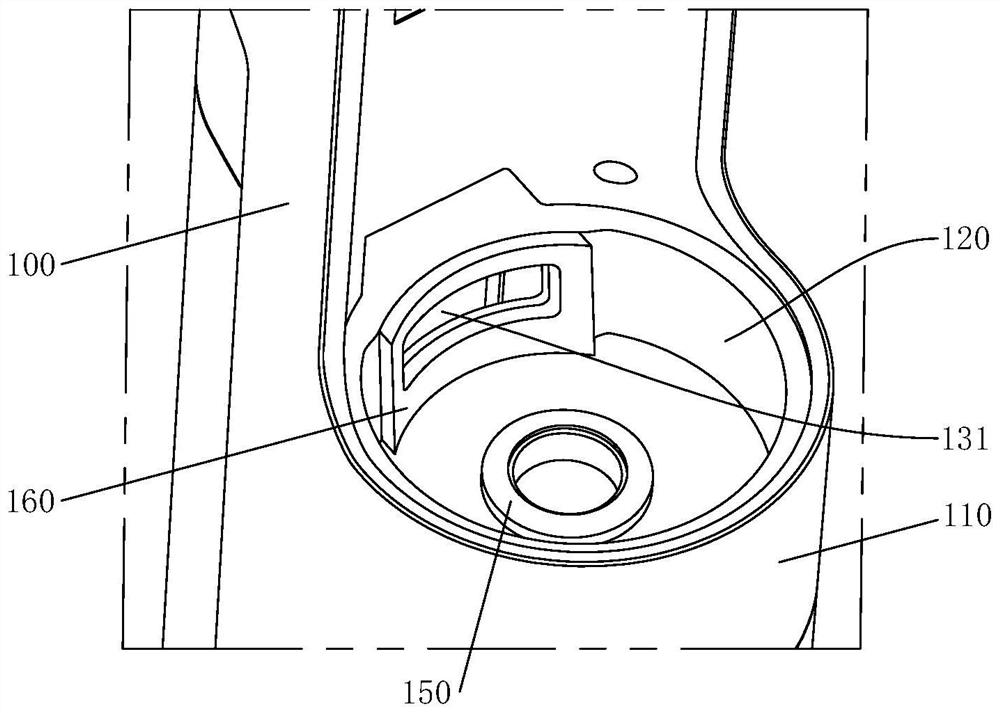

[0047] As an embodiment of the multifunctional surface cleaning machine of the present invention, as Figure 1 to Figure 9As shown, it includes a fuselage 10 with a positioning part 110 and a ground brush 20 pivotally connected to the bottom of the fuselage 10. The positioning part 110 protrudes outward from the fuselage 10. The upper and lower suction source assembly 200 and the dirt bucket 300 . The suction source assembly 200 is provided with an air inlet 210 and an air outlet 220, and the positioning part 110 is provided with a wind direction conversion chamber 120, and the center of the bottom wall of the wind direction conversion chamber 120 is provided with a vent 121 communicating with the dirt bucket 300, An isolating ring 122 is arranged around the vent 121 to isolate the wind direction conversion chamber 120 from the vent 121, and a sound-insulating gasket 150 is arranged inside the isolating ring, and the positioning part 110 includes a circular inner shell 113 and...

Embodiment 2

[0075] As an embodiment of the multifunctional surface cleaning machine of the present invention, as Figure 10 to Figure 12 As shown, the air exhaust cavity 130 is arranged in the positioning portion 110 and extends downward, the inlet 131 of the exhaust cavity 130 is arranged in the air direction conversion cavity 120, the inlet 131 of the exhaust cavity 130 is arranged around the vent 121, and the The inlet 131 of the exhaust chamber 130 is fan-shaped, and the outlet 132 of the exhaust chamber 130 is arranged near the fuselage 10. The projection of the outlet 132 in the horizontal plane does not fall in the inlet 131, and the outlet 132 of the exhaust chamber 130 Located on the bottom side of the positioning part 110, such a structure makes the inlet 131 and outlet 132 of the exhaust chamber not facing each other, ensuring that the wind will not be discharged directly, but enters the exhaust air through the inlet 131 of the exhaust chamber 130 In the cavity 130, the exhaust...

Embodiment 3

[0083]combine Figure 13 The difference between the present embodiment and the first embodiment is that: an air inlet 210 and an air outlet 220 are respectively provided on the front surface of the suction source assembly 200 . Specifically, the air inlet 210 and the air outlet 220 are arranged at different heights on the end surface. Preferably, the air outlet 220 is arranged around the air inlet 210, at Figure 13 , the air outlet 220 is higher than the air inlet 210 .

[0084] In order to make the air inlet passage 111 and the air inlet 210 can seal butt fit, the bottom wall of the wind direction conversion chamber 120 is provided with a sealing ring 150 located on the outer periphery of the top end of the air inlet passage 111 . The positioning part is provided with a buffer cavity, the air outlet of the suction source assembly is connected to one end of the buffer cavity in the wind direction conversion cavity, the buffer cavity is hidden inside the positioning part, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com