Preparation process of amino acid treated composite powder capable of keeping makeup, controlling oil and not draining

A non-sticky, amino acid technology, which is applied in the field of composite powder preparation technology, can solve the problems of high adsorption amount of squalane, inability to evenly attach, and dryness, etc., to reduce the amount of adsorption, improve the feeling of dryness, and eliminate false whites The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

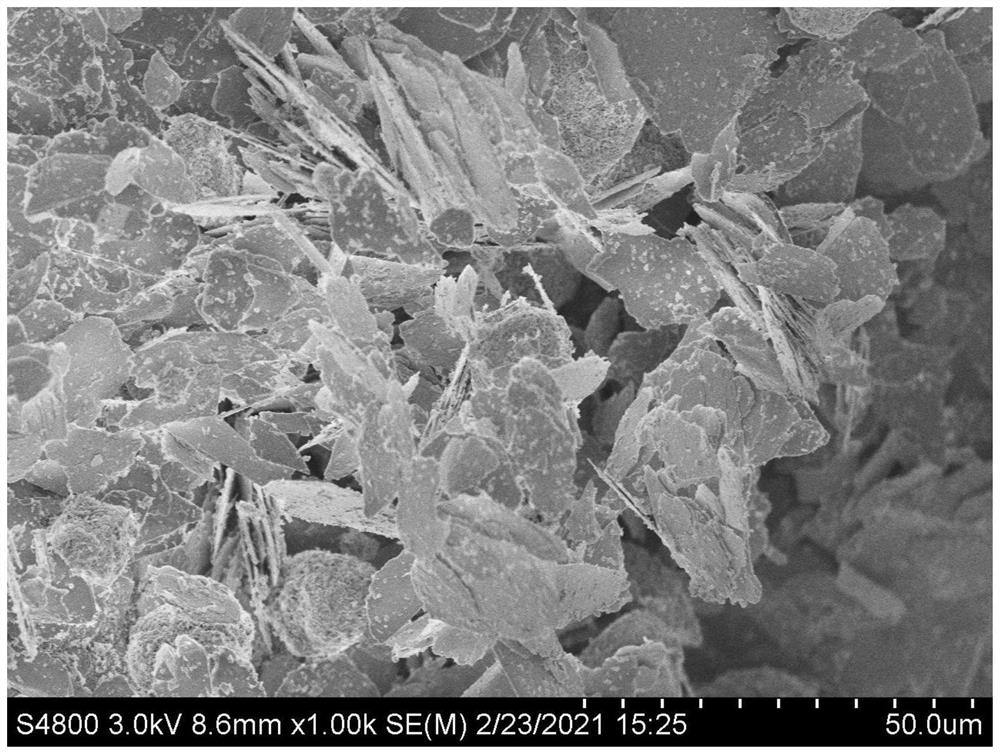

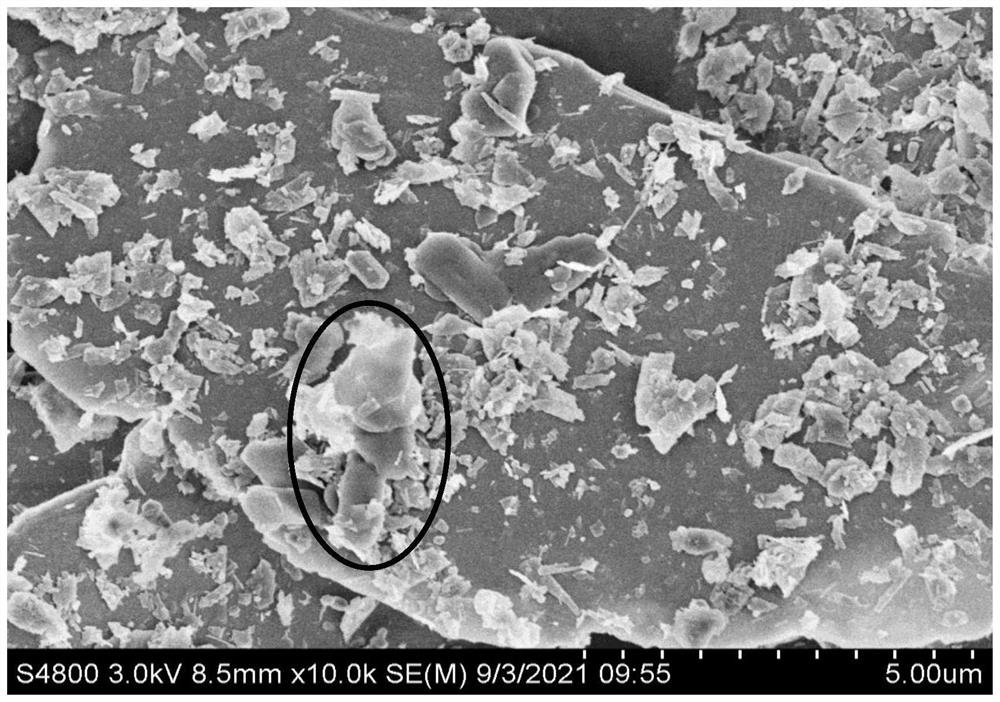

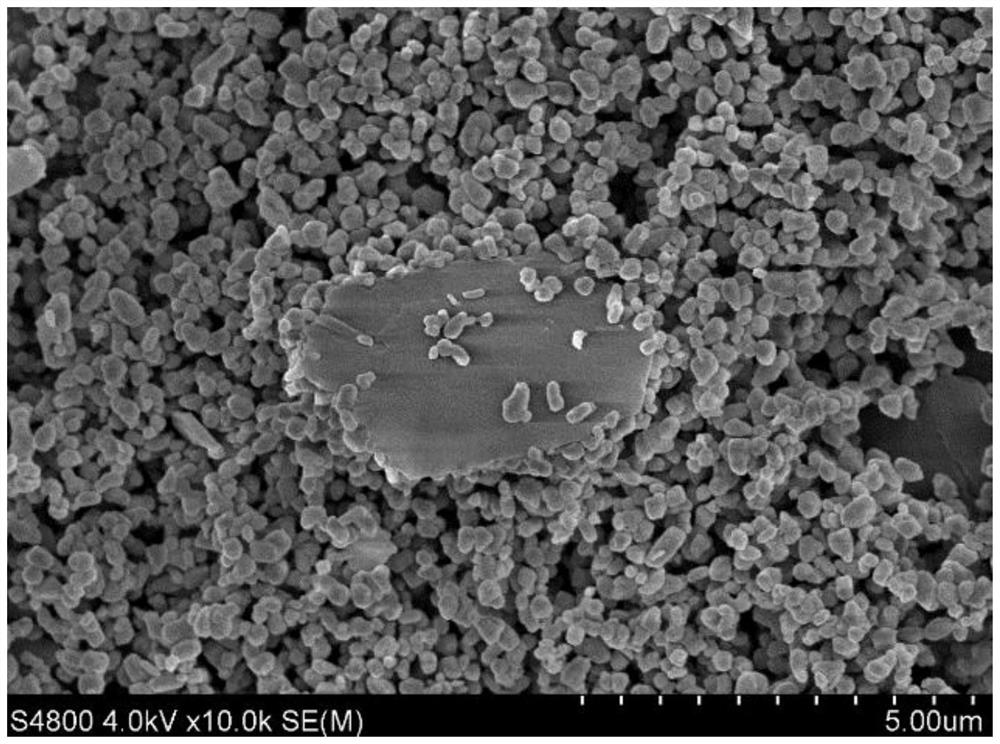

Image

Examples

Embodiment 1

[0037] A preparation process of amino acid-treated composite powder for long-lasting makeup, oil control and non-drying, which comprises the following steps:

[0038] (1) According to the weight calculation, weigh the materials to be delivered:

[0039] Component A: 66 parts of synthetic fluorophlogopite;

[0040] Component B: 15 parts of hydroxyapatite;

[0041] Component C: 10 parts of zinc oxide;

[0042] Component D: 5 parts of lauroyl lysine;

[0043] Component E: 4 parts of triethoxyoctylsilane;

[0044] (2) Component A is placed in the reactor, put in 3-5 times the deionized water according to the weight of component A, the rotation speed of the reactor is set at 300-500rpm, the temperature is set at 60-80°C, and continuous dispersion 20-40 minutes;

[0045] (3) supplement 60-80 DEG C deionized water of 1-2 times according to component A weight in reactor;

[0046] (4) Component B is put into the slurry in the reactor, and then component C is added, and the rotati...

Embodiment 2

[0056] A preparation process of amino acid-treated composite powder for long-lasting makeup, oil control and non-drying, which comprises the following steps:

[0057] (1) According to the weight calculation, weigh the materials to be delivered:

[0058] Component A: 83 parts of mica;

[0059] Component B: 10 parts of hydroxyapatite;

[0060] Component C: 3 parts of zinc oxide;

[0061] Component D: 2 parts of at least one of lauroyl sarcosine;

[0062] Component E: 2 parts of at least one of triethoxyoctylsilane and polydimethylsiloxane;

[0063] (2) Component A is placed in the reactor, put in 3-5 times the deionized water according to the weight of component A, the rotation speed of the reactor is set at 300-500rpm, the temperature is set at 60-80°C, and continuous dispersion 20-40 minutes;

[0064] (3) supplement 60-80 DEG C deionized water of 1-2 times according to component A weight in reactor;

[0065] (4) Component B is put into the slurry in the reactor, and then c...

Embodiment 3

[0075] A preparation process of amino acid-treated composite powder for long-lasting makeup, oil control and non-drying, which comprises the following steps:

[0076] (1) According to the weight calculation, weigh the materials to be delivered:

[0077] Component A: 75 parts of talcum powder;

[0078] Component B: 12 parts of hydroxyapatite;

[0079] Component C: 5 parts of zinc oxide;

[0080] Component D: 4 parts of at least one of lauroyl lysine and lauroyl sarcosine;

[0081] Component E: 4 parts of at least one of triethoxyoctylsilane and polydimethylsiloxane;

[0082] (2) Component A is placed in the reactor, put in 3-5 times the deionized water according to the weight of component A, the rotation speed of the reactor is set at 300-500rpm, the temperature is set at 60-80°C, and continuous dispersion 20-40 minutes;

[0083] (3) supplement 60-80 DEG C deionized water of 1-2 times according to component A weight in reactor;

[0084] (4) Component B is put into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com