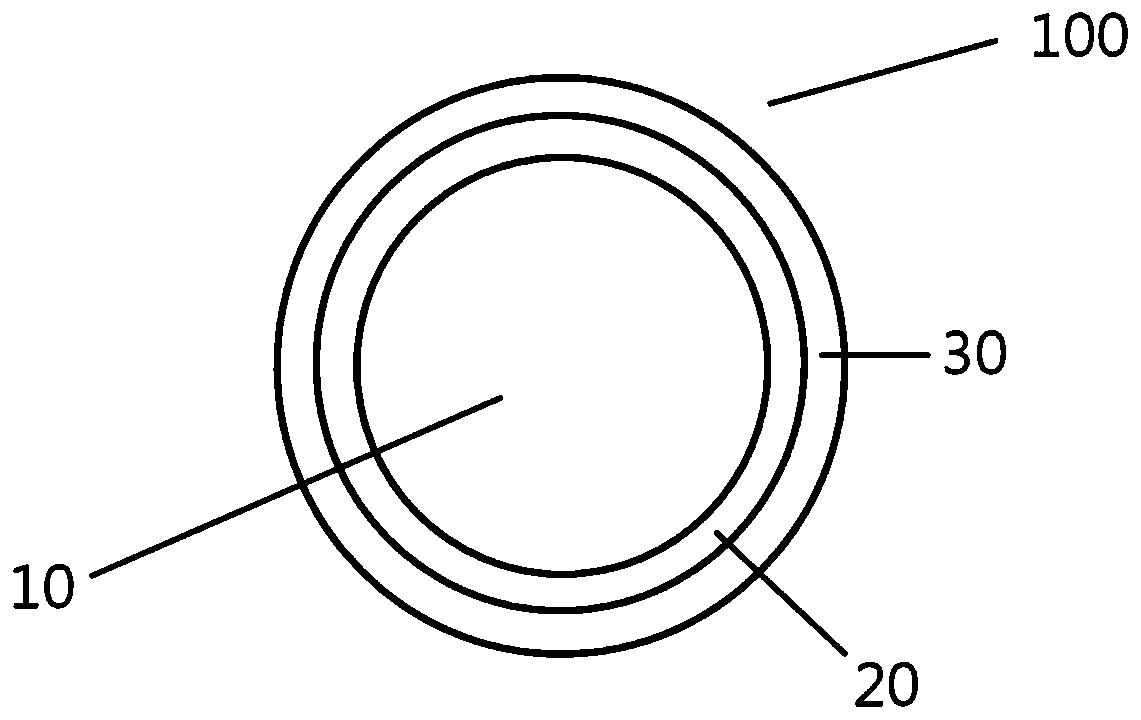

Spherical zinc oxide powder coated with natural substance, method for producing same, and cosmetic composition containing same

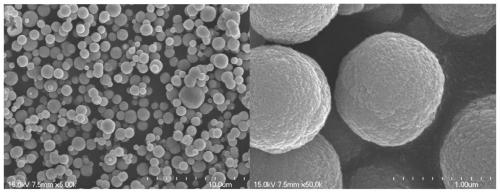

A technology of cosmetic composition and zinc oxide powder, which is applied in the field of zinc oxide powder, can solve the problems of reduced sense of use, uneven particle shape, poor sphericity, etc., to improve safety, Improved cost competitiveness and excellent particle dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

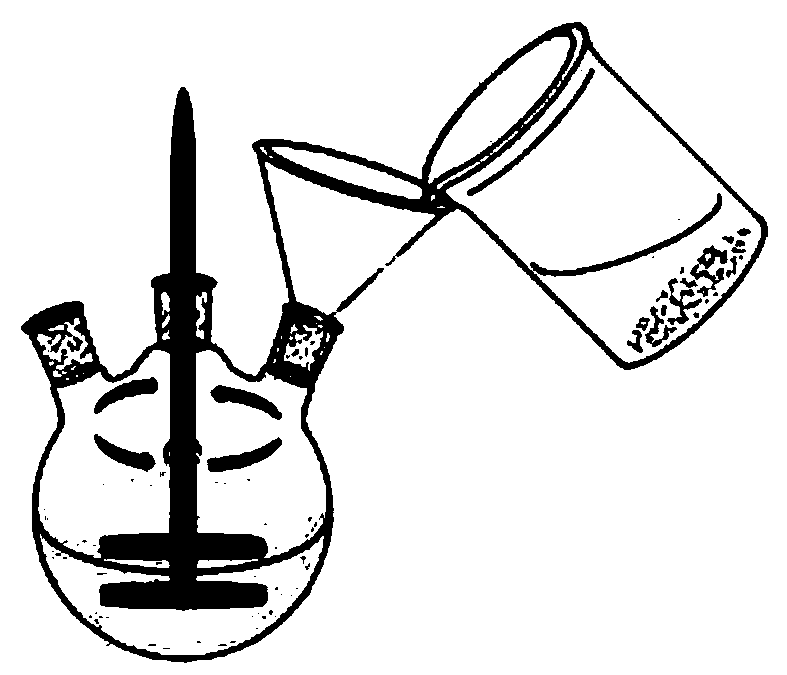

[0071] In a reactor, 1000 g of water, 200 g of amorphous zinc oxide, and 400 g of citric acid were mixed and stirred for dissolution. Into the above reactor such as figure 2 In this way, 350 g of NaOH (700 g of NaOH diluted to 50% by weight) was injected into the reactor along the wall surface of the reactor. When the above-mentioned input of NaOH, the stirring speed of the reactor was slowly accelerated from 100rpm to 400rpm in 10 minutes, and the input speed of sodium hydroxide was slowly reduced from 10ml / s to 5ml / s according to the mode of 0.05ml per second. And, it was further stirred for 10 minutes at 400 rpm as the final stirring speed, so that the total stirring time was 20 minutes. At this time, the stirring temperature was 60°C.

[0072] Next, after decelerating the stirring speed of the reactor to 150 rpm, dehydration reaction was performed at 95 degreeC for 24 hours.

[0073] Next, 40 g of TEOS and 40 g of ethanol were mixed and charged into the reactor, and re...

Embodiment 2

[0076] In said Example 1, except having used cocoa butter instead of lauroyl lysine, the spherical zinc oxide powder coated with cocoa butter was produced by the method similar to said Example 1.

Embodiment 3

[0078] In said Example 1, except having used lecithin instead of lauroyl lysine, the spherical zinc oxide powder coated with lecithin was produced by the method similar to said Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com