Hydrophobic polysaccharide microspheres, preparation method thereof and cosmetics

A technology of hydrophobicity and hydrophobicity modification, which is applied in cosmetics, cosmetic preparations, dressing preparations, etc. It can solve the problems of poor hydrophobicity of natural polysaccharide microspheres and achieve a smooth and delicate hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

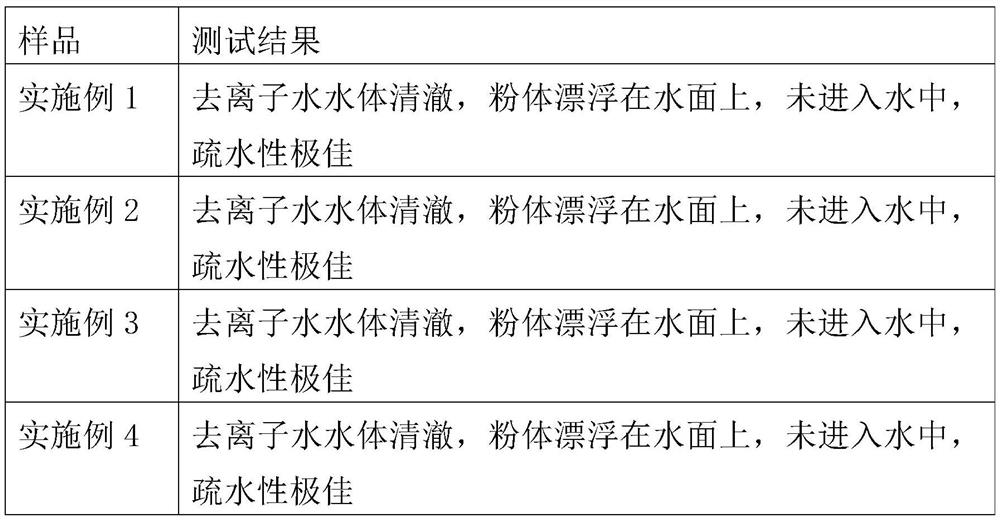

Examples

preparation example Construction

[0024] Preparation of Hydrophobic Polysaccharide Microspheres

[0025] An embodiment of the first aspect of the present application provides a method for preparing hydrophobic polysaccharide microspheres, which includes the following steps: providing polysaccharide microspheres made of natural polysaccharide materials; the hydrophobic modification step includes mixing a lauroyl lysine solution with the prepared polysaccharide microspheres. The polysaccharide microspheres are contacted so that lauroyl lysine is bound to at least part of the surface of the polysaccharide microspheres to obtain hydrophobic polysaccharide microspheres.

[0026] Natural polysaccharide microspheres are a class of natural polysaccharide materials with the advantages of being renewable, biodegradable, safe and pollution-free, chemically stable, easy to modify, and biocompatible, such as cellulose, chitin, and chitosan. Wait. Compared with inorganic microspheres and organic polymer microspheres, natu...

Embodiment 1

[0057] The preparation method of the hydrophobic polysaccharide microspheres provided in this embodiment comprises the following steps:

[0058] Dissolve 0.2g lauroyl lysine powder in 39.8g sodium carbonate / sodium bicarbonate buffer solution (pH range 9-10); disperse 2g cellulose ball powder in 38g citric acid / sodium citrate buffer solution (pH range 9-10); Range 4-5), add 0.6g sodium chloride aqueous solution (30% mass concentration), stir at 600rpm for 1h; slowly add lauroyl lysine solution (drop rate 0.5g / min) to the cellulose microsphere dispersion liquid, After the dropwise addition, stirring was continued for 1 h; deionized water was centrifuged, the precipitate in the system was washed three times, and cellulose microspheres modified with lauroyl lysine were obtained after freeze-drying.

Embodiment 2

[0060] The preparation method of the hydrophobic polysaccharide microspheres provided in this embodiment comprises the following steps:

[0061] Dissolve 0.5g lauroyl lysine powder in 39.5g borax / sodium hydroxide buffer solution (pH range 9-10); disperse 3g chitosan microsphere powder in 37g citric acid / sodium citrate buffer solution ( pH range 4-5), add 0.6g magnesium chloride aqueous solution (20% mass concentration), stir at 300rpm for 1h; slowly add lauroyl lysine solution dropwise to the chitosan microsphere dispersion (drop rate 0.3g / min), After the dropwise addition was completed, stirring was continued for 1 h; the precipitate in the system was obtained by suction filtration, washed with deionized water three times, and freeze-dried to obtain lauroyl lysine-modified chitosan microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com